Processing technology of spinning belt pulley with inner and outer lug bosses

A processing technology and pulley technology, applied in the field of spinning pulley processing technology, can solve problems such as low cost, waste of materials, high energy consumption efficiency, etc., and achieve the effects of wide sources, convenient process and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and a preferred embodiment:

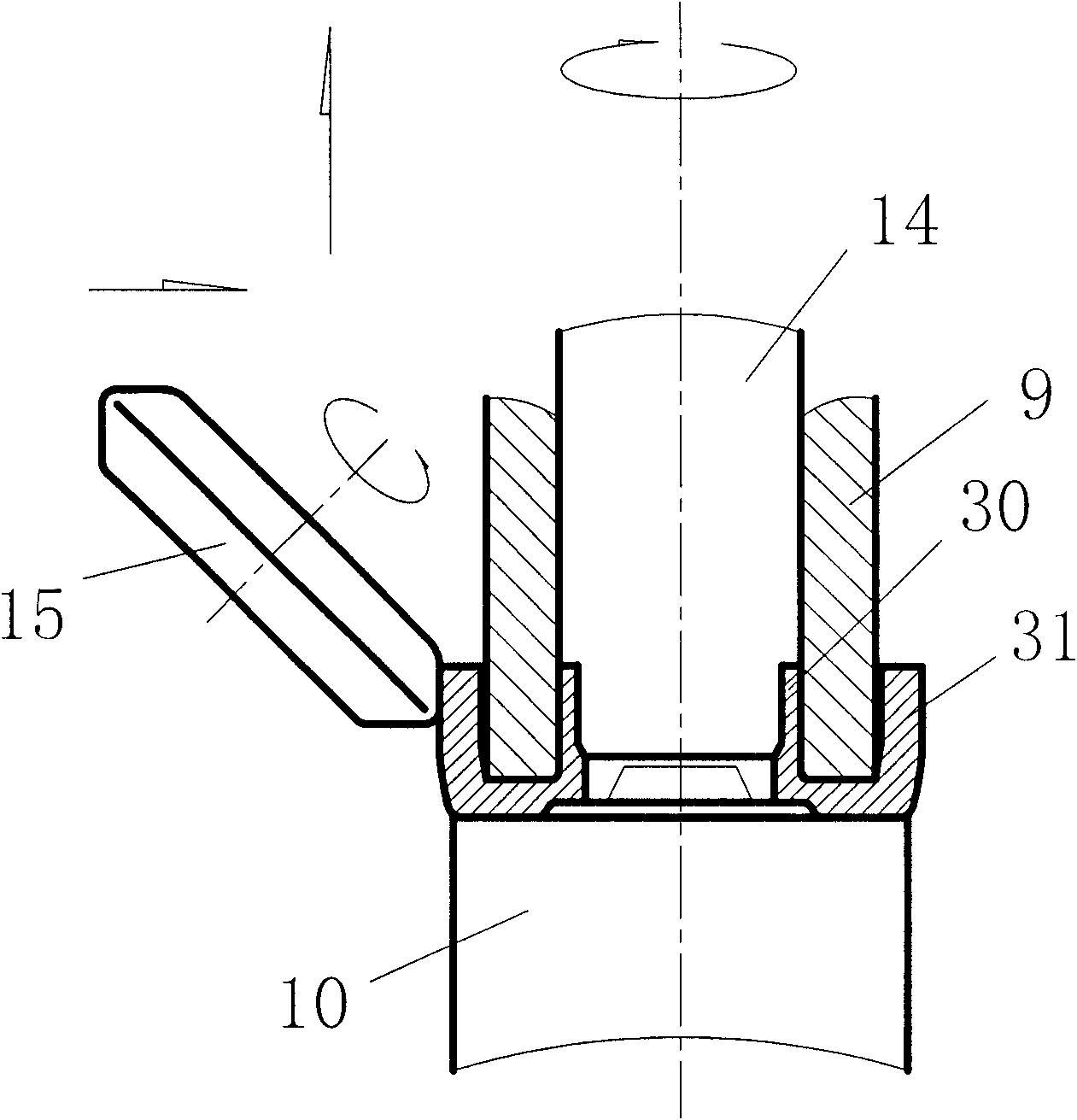

[0033] The processing technology of the spinning belt pulley with inner and outer bosses, including stamping and preforming the blank, and reprocessing the preformed blank (such as figure 2 , 3 , shown in 4), the reprocessed preformed blank is carried out by spinning (such as Figure 5 , 6 shown).

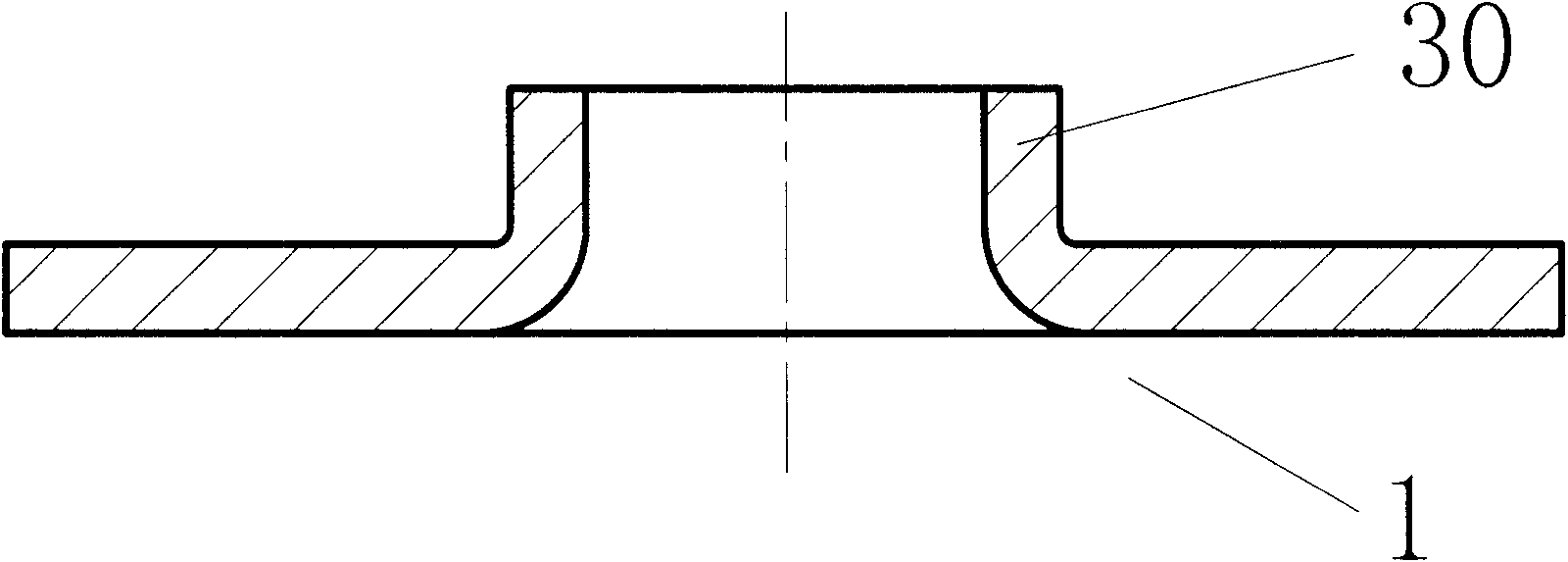

[0034] First, carry out stamping preforming to blank, be that blank is stretched and punched through stamping, makes it form the A preformed blank 1 of the flange shape disk shape with inner boss 30 (its cross-sectional view is as follows figure 1 shown).

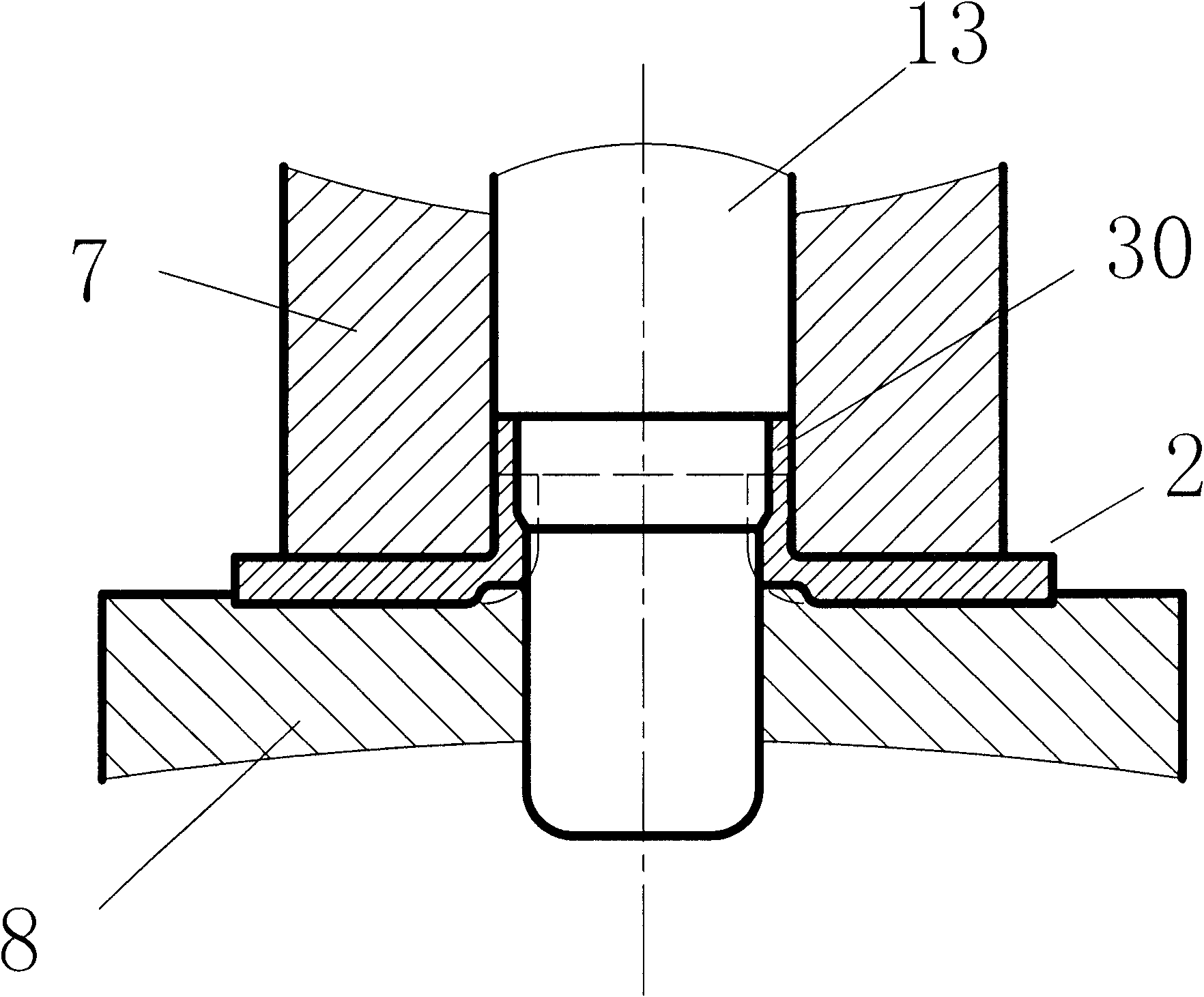

[0035] Secondly, the reprocessing of the preform is to extrude the A preform 1 into a B preform 2 with a predetermined size through cold extrusion. During cold extrusion, the A preform blank 1 is clamped between the stamping upper die 7 and the stamping lower die 8, and the stamping core 13 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com