Electric rail-defect detecting car

A rail flaw detection car, electric technology, applied in the direction of railway inspection car, etc., can solve the problems of low detection efficiency, poor detection effect, high detection cost, etc., and achieve the effect of high detection efficiency, easy disassembly and assembly, and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

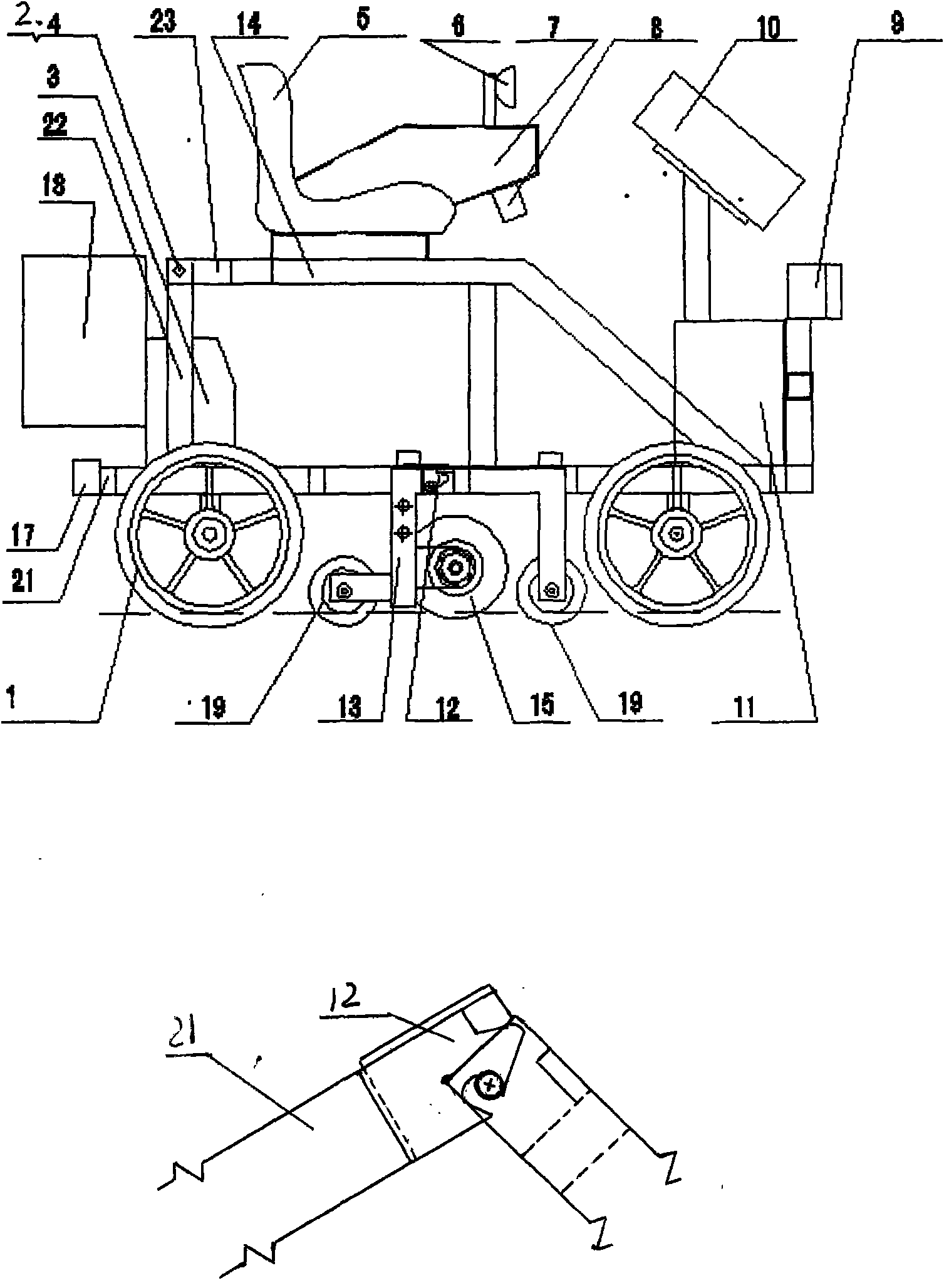

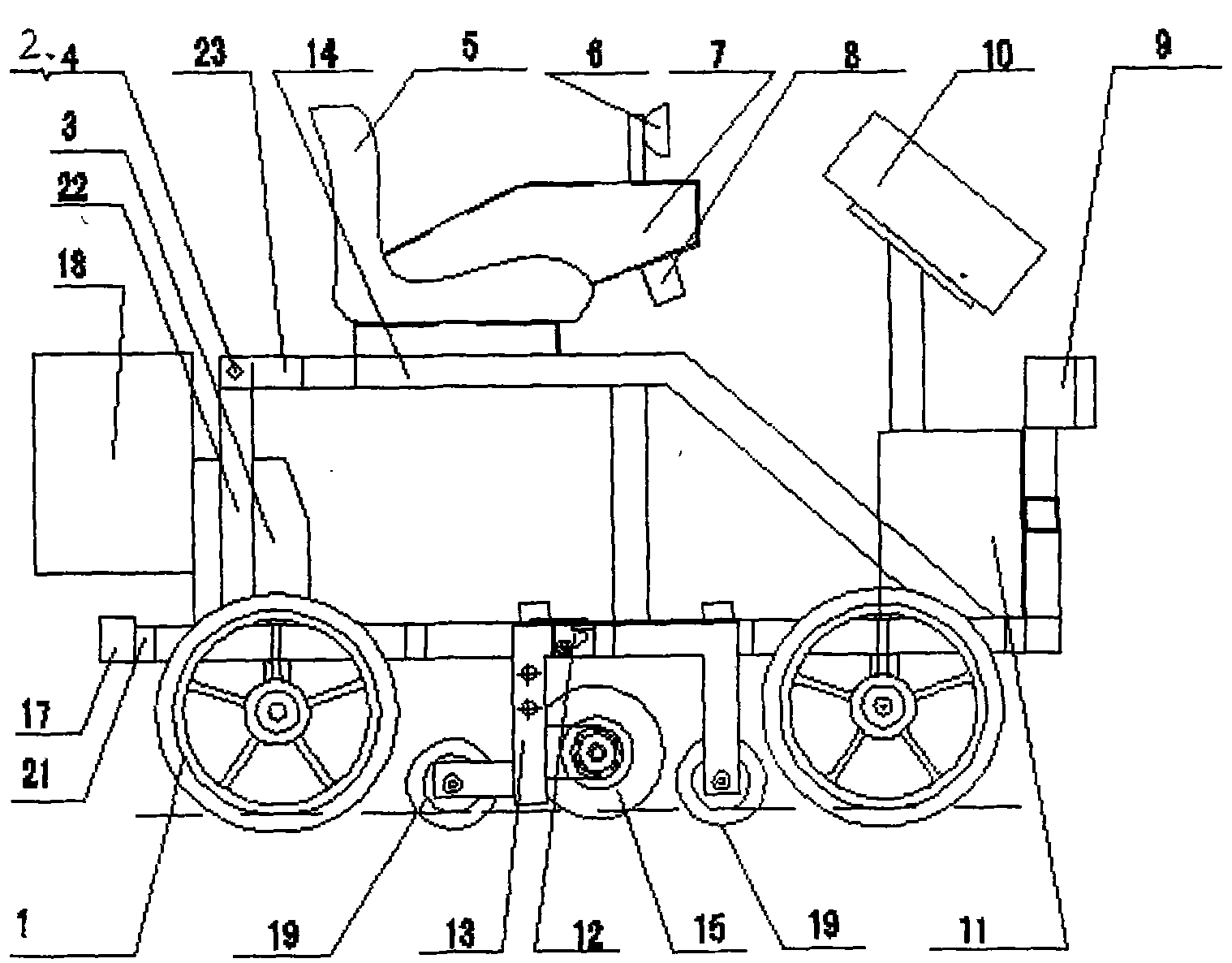

[0009] As shown in Figures 1 and 2, the electric rail flaw detection trolley includes a rail wheel, a vehicle frame and a rail flaw detector. Vehicle frame 2 is made of base plate, support rod and upper link, and base plate 21 is two front and back, is connected by hinge 12 between front and rear two base plates. The front, rear, left, and right sides below the base plate are equipped with rail wheels 1 respectively. Rail wheel 1 is a wheel with a rim to ensure that the trolley runs along the rails. A battery box 11 is installed on the front block base plate of the vehicle frame, and a driving motor 3 is installed on the rear block base plate. The supporting rod 22 at the back of the vehicle frame and the upper link 23 are connected by a positioning pin 4, and the front end of the upper link is bent and fixed on the front base plate. Flaw detector 10.

[0010] The water wheel type probe 15 connected by the rail water wheel support 13 and the automatic adjustment wheel 19 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com