Cab

A driver's cab and column technology, applied in the field of driver's cab, can solve the problems of difficulty in installing the fiberglass hood, lack of protection for the driver, heavy weight, etc., and achieve the effect of high rigidity, good driver comfort, and spacious interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

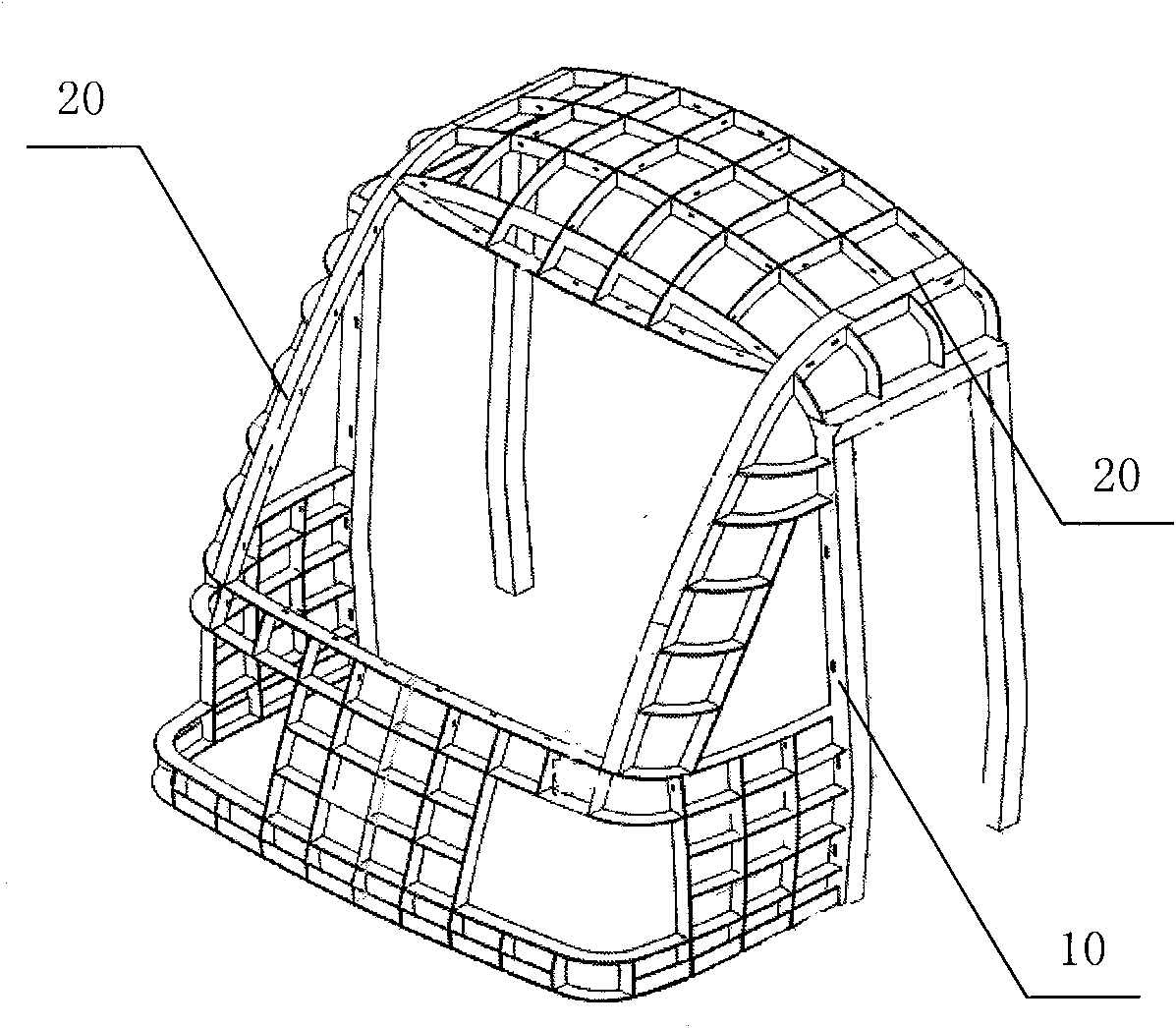

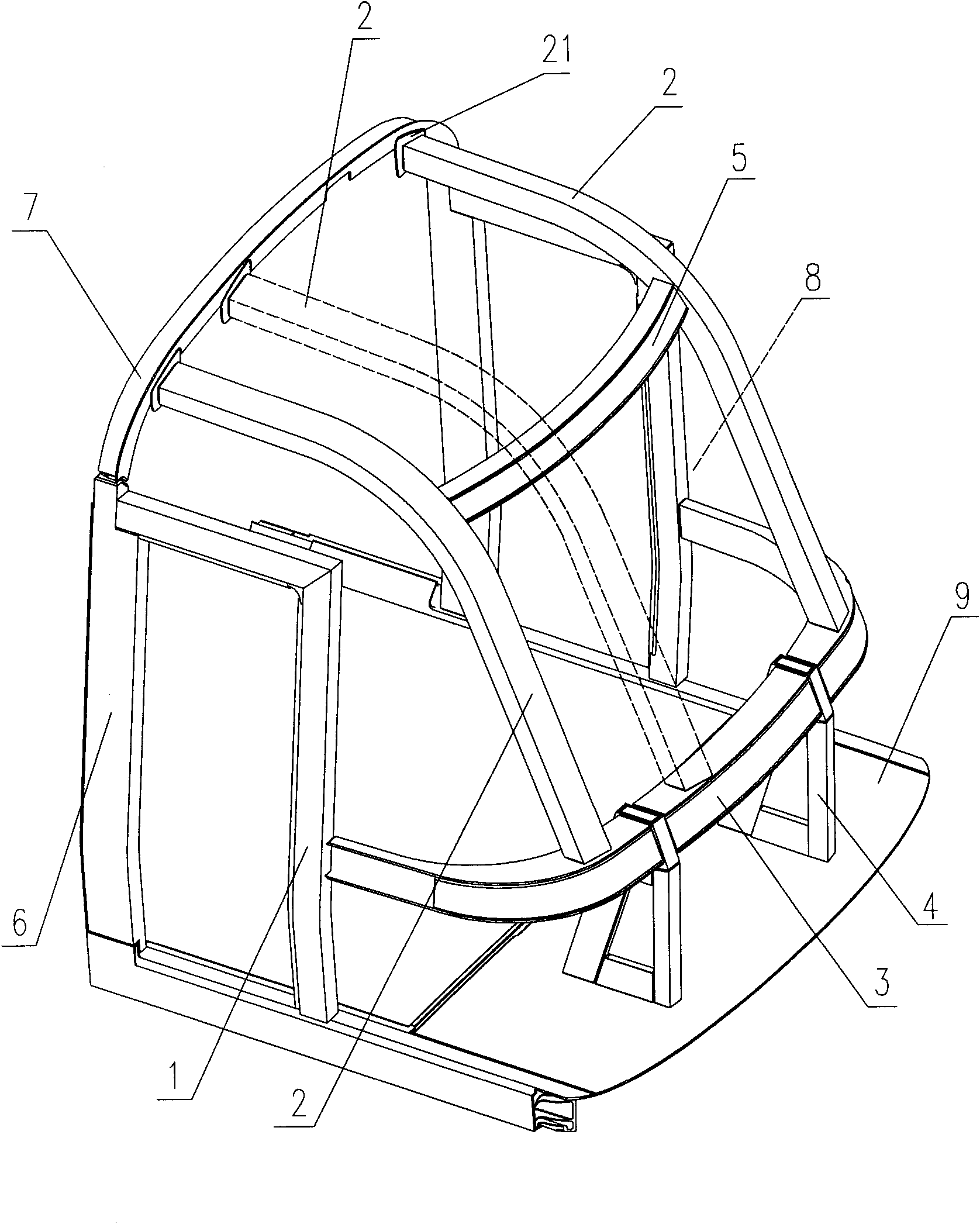

[0013] see figure 2 As shown, the present invention is a driver's cab, which is composed of two door columns 1, two longitudinal beams 2, a main beam 3, two main columns 4, and an upper beam 5. become. The cab can also adopt a modular design for easy assembly.

[0014] Among them, the two door columns 1 are L-shaped and are located on both sides of the driver's cab. The two ends of the door column 1 are respectively welded to the side wall 6; one end of the longitudinal beam 2 is welded to the top cover 7, and the other end is welded to the main On the cross beam 3, in practice, one end of the longitudinal beam 2 is welded with a fixed block 21, and the contact area between the longitudinal beam 2 and the top cover 7 can be increased by welding the fixed block 21 with the top cover 7; Between beam 2, its two ends are respectively welded on the two longitudinal beams 2, and the space enclosed by the lower end of the upper beam 5 and the two longitudinal beams 2 is the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com