Bridge wheel valve assembly of central inflation and deflation system of automobile tyres

A technology for car tires, inflation and deflation, which is applied to multi-way valves, valve devices, engine components, etc. High speed, improved mobility and survivability, light weight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

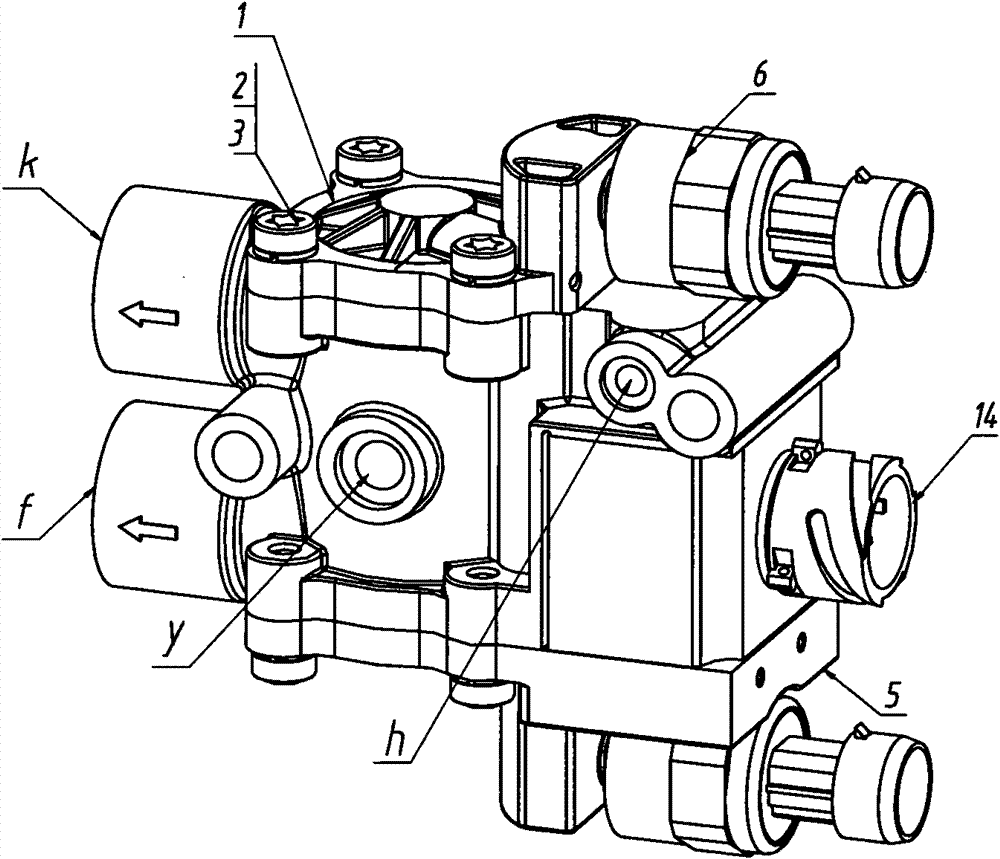

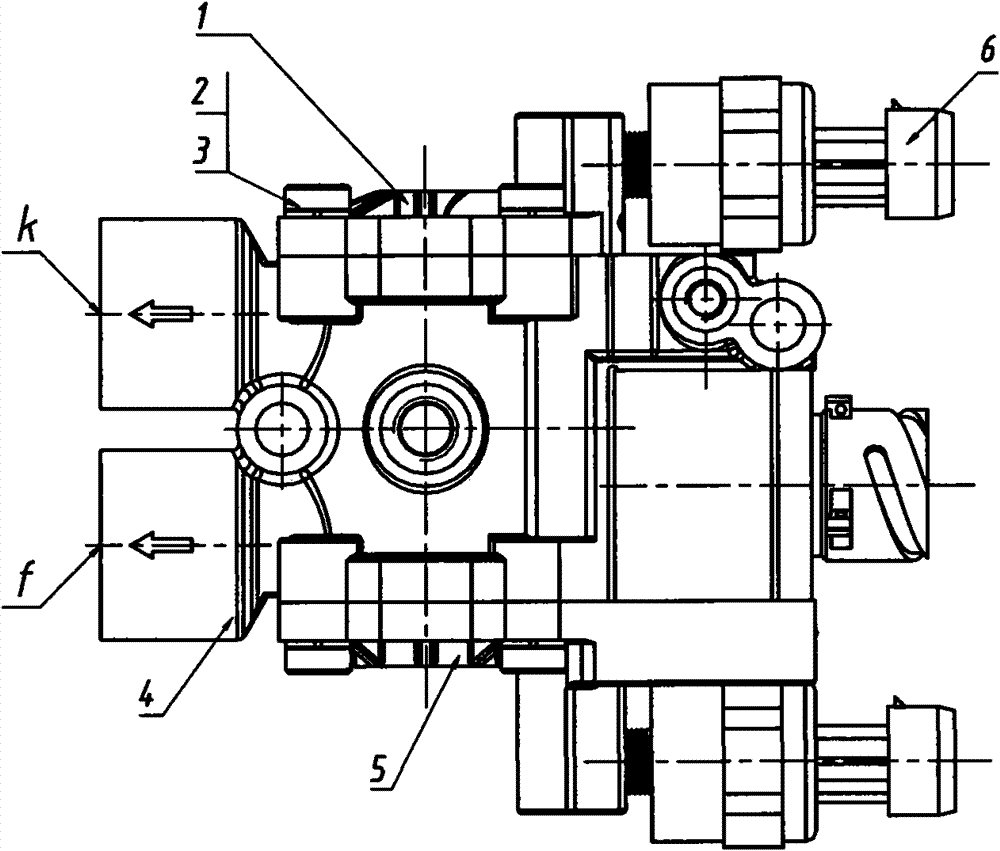

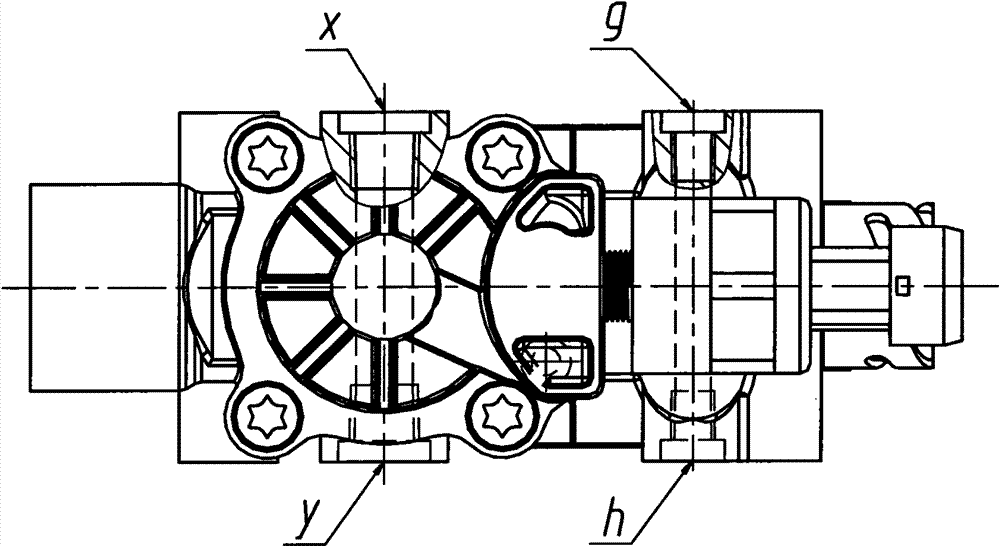

[0065] Below in conjunction with accompanying drawing and example describe in detail:

[0066] 1. Overall

[0067] Depend on Figure 1-14 It can be seen that the present invention includes a bridge wheel valve cover 1, a hexagon socket head screw 2, a spring washer 3, a bridge wheel valve body 4, a bridge wheel solenoid valve cover 5, a pressure sensor 6, a gasket 7, a diaphragm 8, and a spring 9 , O-ring 10, steel ball 11, saddle spring washer 12, dust pad 13 and solenoid valve assembly 14;

[0068] Its location and connection relationship are:

[0069] like Figure 12 , from top to bottom, hexagon socket head screw 2, spring washer 3, bridge wheel valve cover 1, steel ball 11, pressure sensor 6, spring 9, diaphragm 8, gasket 7, O-ring 10, bridge wheel The valve body 4, the solenoid valve assembly 14 and the bridge wheel solenoid valve cover 5 are sequentially connected;

[0070] The gasket 7, the diaphragm 8 and the O-ring 10 are positioned by the corresponding holes on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com