Pulse-type steel wire displacement sensor

A displacement sensor, pulse type technology, applied in the direction of instruments, signal transmission systems, measuring devices, etc., can solve the problems of high price, low sensitivity, small range, etc., and achieve the effect of cheap price, high sensitivity, and large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

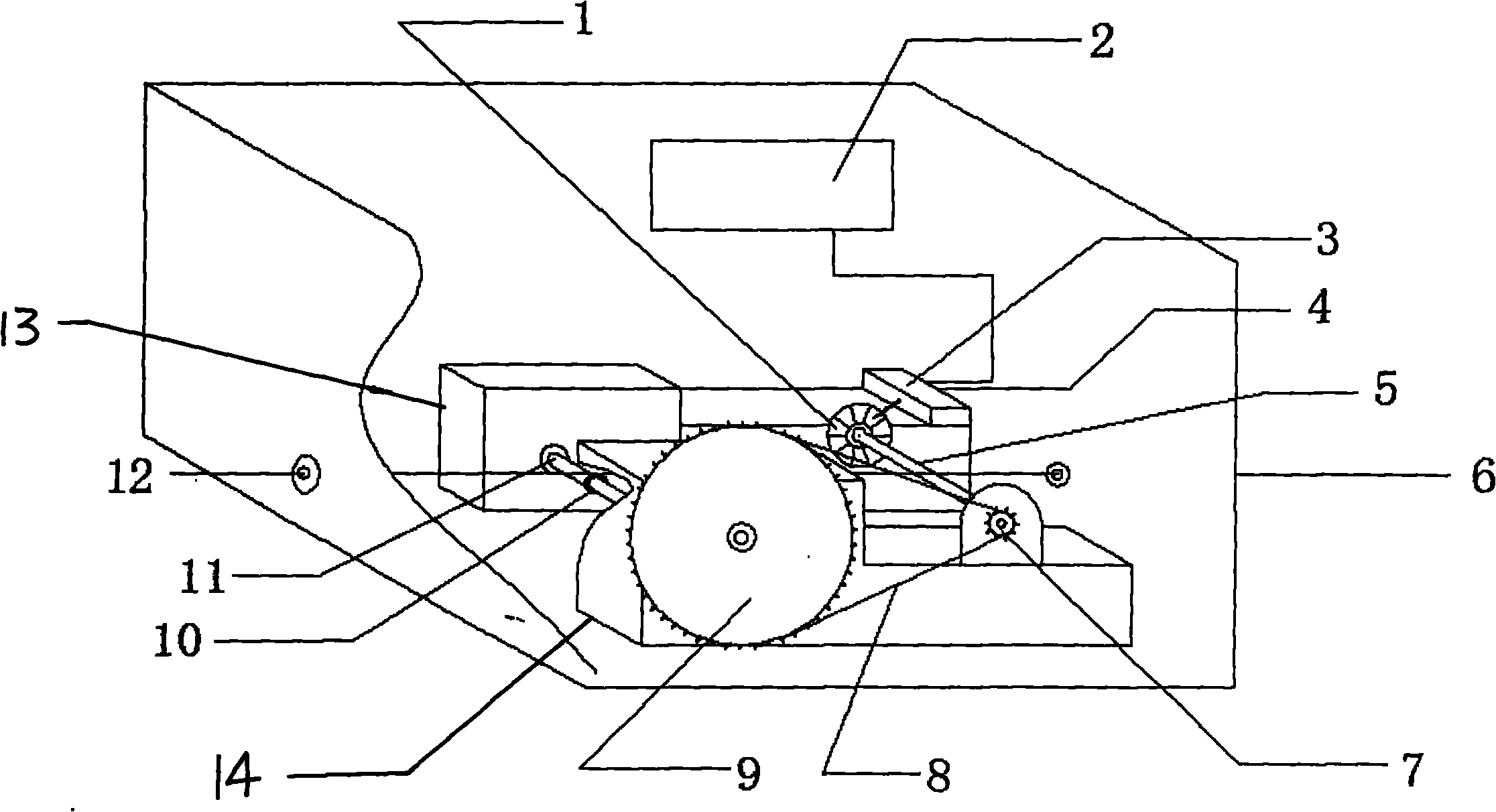

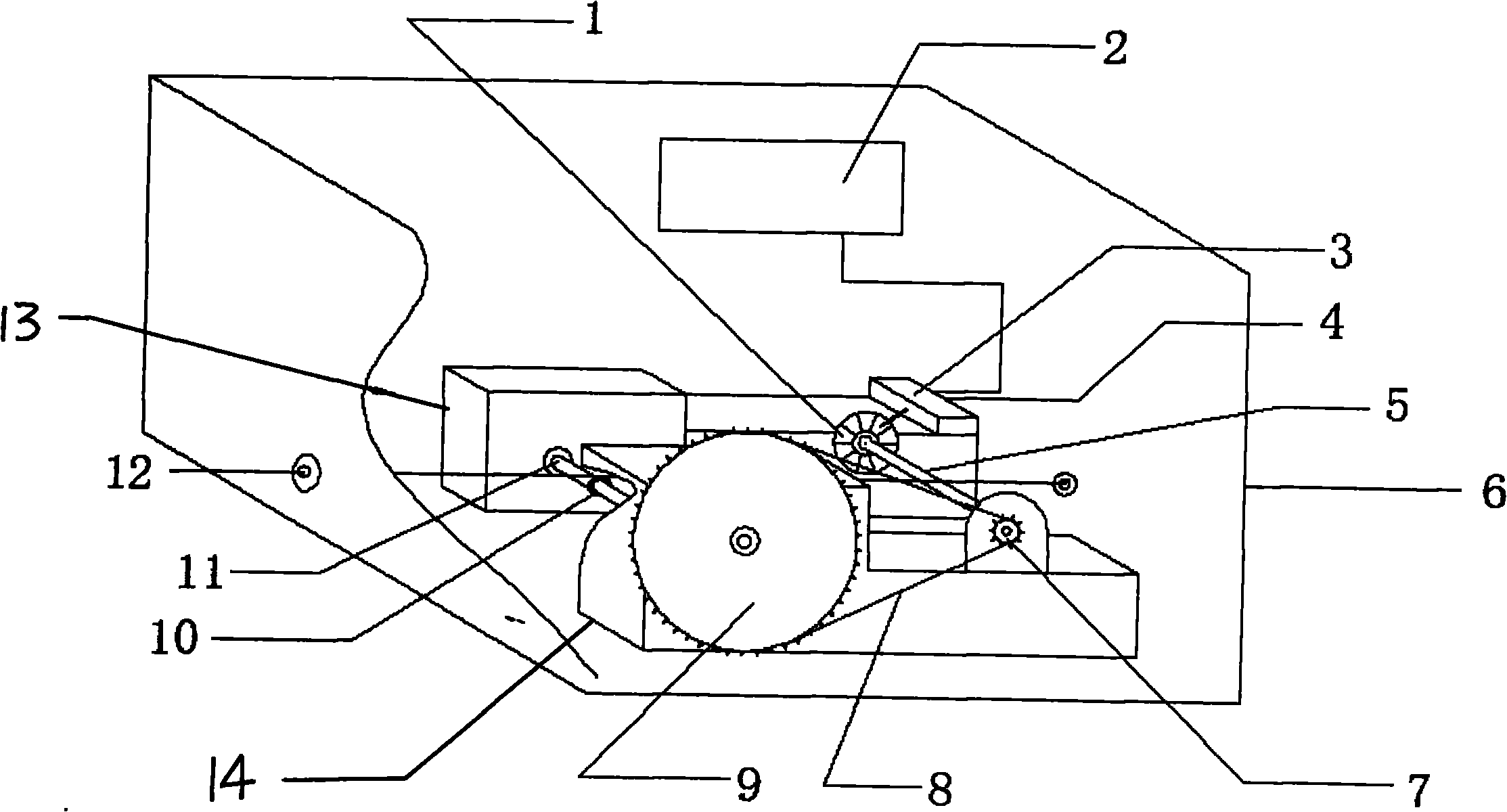

[0009] With reference to the drawings, the steel wire 12 bypasses the grooved pulley 10, and the linear motion of the steel wire drives the pulley to rotate. The pulley is fixed on the rotating shaft 11, and both ends of the rotating shaft are fixed on the supports 13, 14 through bearings. The large gear 9 is fixed on the rotating shaft 11, and the pulley 10 and the large gear 9 rotate in unison. The large gear 9 and the small gear 7 are connected by a chain 8 to form a displacement amplification device. The small gear and the pulley switch 1 are fixed on another rotating shaft 5, and the two ends of the rotating shaft 5 are also fixed on the supports 13, 14 through bearings. Contacts are uniformly arranged on the pulley switch 1, and when the contacts are in contact with the switch of the pulse generator 3, pulses are generated. The number of pulses can be obtained through the counter and digital display device 2. The pulse can also be transmitted to the transmitter through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com