Machining center PLC integration method

A machining center and function technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of increased program steps, integrated design, debugging and maintenance difficulties, etc., and achieve the effect of saving scanning time and shortening execution cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

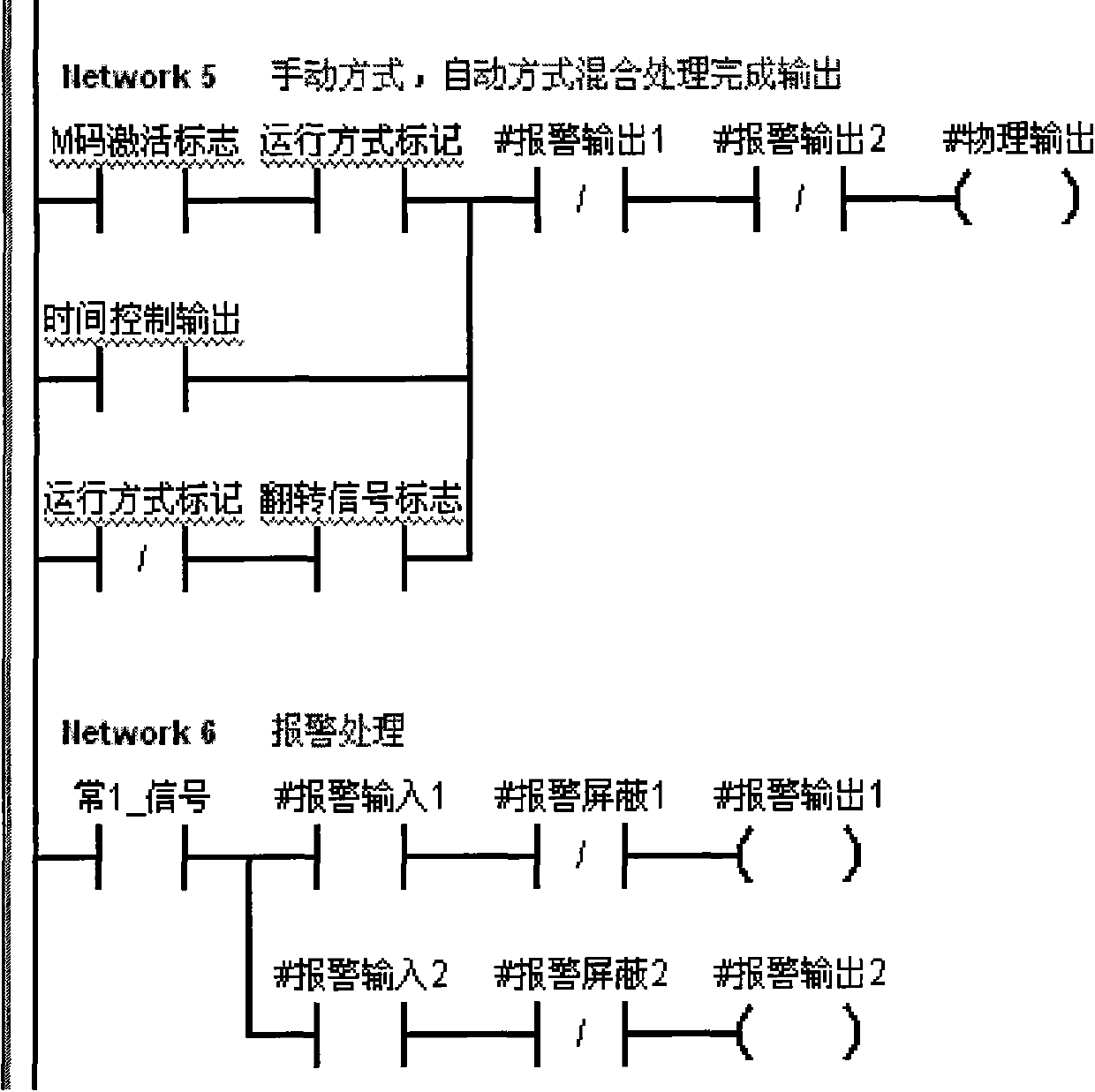

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] figure 1 Shown, the system that the present invention adopts comprises following unit:

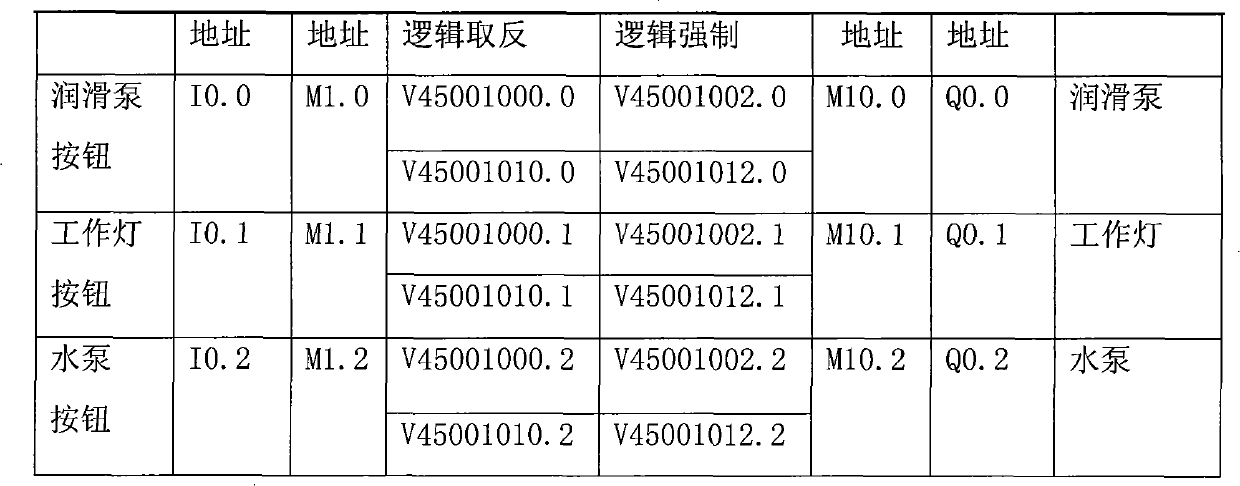

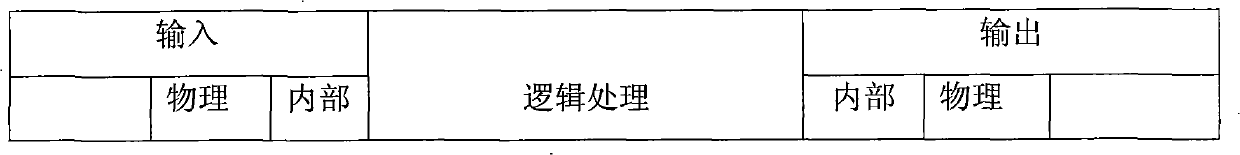

[0023] The input and output filter processing module 1 completely and uniquely maps the physical addresses therein to the internal memory 5 , while the addresses of the other functional modules use all external input and output mappings of the internal memory 5 .

[0024] The input and output logic processing module 2 precisely processes the positive and negative logic and forced logic of the physical address, and is connected with the internal memory 5 through the PLC parameter setting module 6 .

[0025] The function selection module 3 is used for the definition of each local variable in the program control and manual control mixed programming module 4, and will generate the calling of the variable quantity and form of the function module when the function is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com