Electrolyte and lithium-ion secondary battery

A technology of electrolyte and electrolyte salt, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of lower cycle performance of lithium ion secondary batteries, and achieve the effect of good normal temperature cycle performance and good low temperature discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to the preparation method of the non-aqueous electrolytic solution of the present invention: the siloxane of ethylene carbonate, propylene carbonate, the low-viscosity organic solvent whose viscosity is not greater than 1mPa·s at normal temperature, the siloxane of formula (1) is mixed according to the ratio of the present invention Mix in a dry environment to form a mixed solvent, then add the electrolyte salt into the above mixed solvent, heat and stir to completely dissolve the electrolyte salt, and prepare the non-aqueous electrolyte solution according to the present invention. The purpose of heating the mixed solvent is to quickly and completely dissolve the electrolyte salt, and has little effect on the non-aqueous electrolyte itself, as long as the electrolyte salt can be completely dissolved.

[0036] A lithium ion secondary battery according to the present invention comprises a battery casing, an electrode group and an electrolyte, the electrode group ...

Embodiment 1

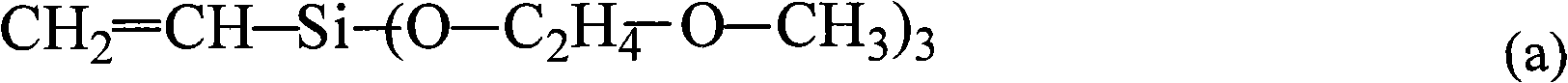

[0041] Select the siloxane of structural formula (a) for use:

[0042]

[0043] 1. Electrolyte Preparation

[0044] Weigh 30 grams of EC, 20 grams of PC, 50 grams of DEC, and 10 grams of siloxane of the above formula (a), mix the above four substances evenly, and then add LiPF 6 Make the concentration reach 1mol / L, heat and stir at 50°C to make LiPF 6 Dissolve completely to obtain an electrolyte solution. The siloxane of the above formula (a) accounts for 9.1 wt% of the mixed solvent.

[0045] 2. Preparation of Cathode

[0046] Weigh 92 grams of LiFePO 4, 4 grams of carbon black and 4 grams of polyvinylidene fluoride (PVDF), the above three kinds of materials were dissolved in 100g N-N dimethylpyrrolidone (NMP), fully stirred and mixed evenly to make positive electrode slurry. The positive electrode slurry was evenly coated on an aluminum foil with width×thickness=200mm×16mm by a pulper. Then put the aluminum foil coated with the positive electrode slurry into a vacuu...

Embodiment 2~6

[0061] According to the method of Example 1, the difference is the selection and content of each component in the mixed solvent, as shown in Table 3 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com