System debugging method for DC ice melting device

A technology of DC ice melting and debugging method, which is applied to measurement devices, program control devices, software testing/debugging, etc., can solve the problems of transmission lines threatening the safe operation of power systems, etc., and achieve the effect of reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

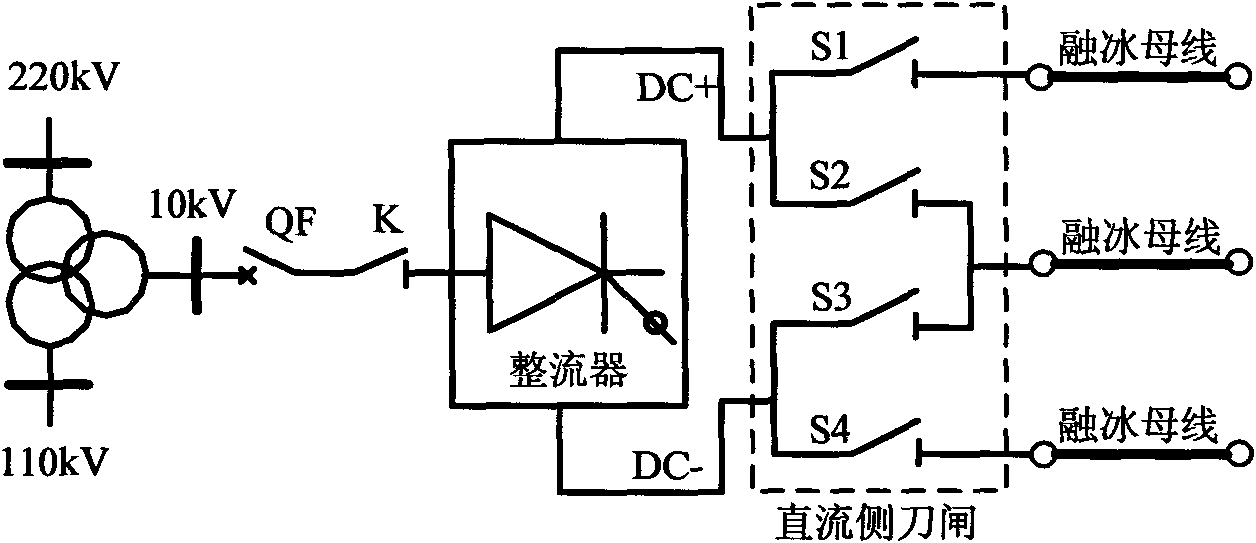

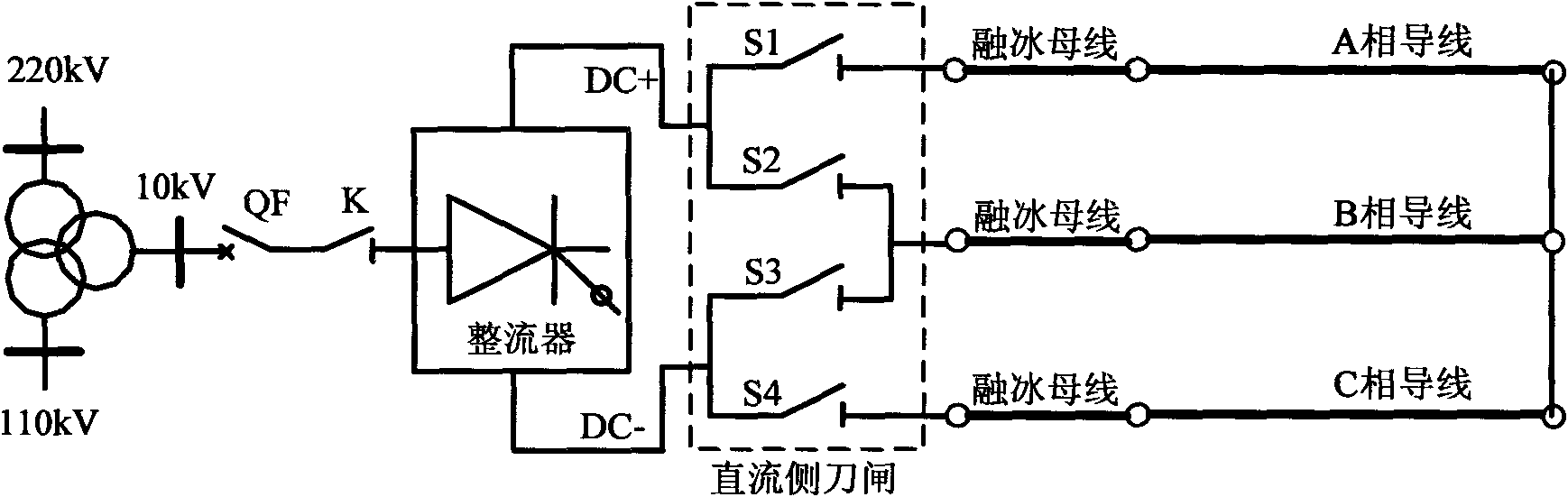

[0049] For the system commissioning schematic diagram of DC ice melting device without special rectifier transformer, see figure 1 and figure 2 . (1) Combined with the DC deicing device, use the substation to analyze and calculate the voltage level and system stability of various commissioning conditions by using the electromechanical transient simulation program, and formulate the accident plan. In the electromagnetic transient simulation program, an equivalent power supply model including the detailed control and protection functions of the DC deicing device is established, and the start-stop sequence of the DC deicing device, the filter switching strategy, control and protection functions and parameters, and the conversion of working conditions are tested, and The harmonics and reactive power of the DC deicing device under various working conditions are analyzed. (2) figure 1 In the process, the DC side knife switches S1, S2, S3 and S4 are kept disconnected, and the swi...

Embodiment 2

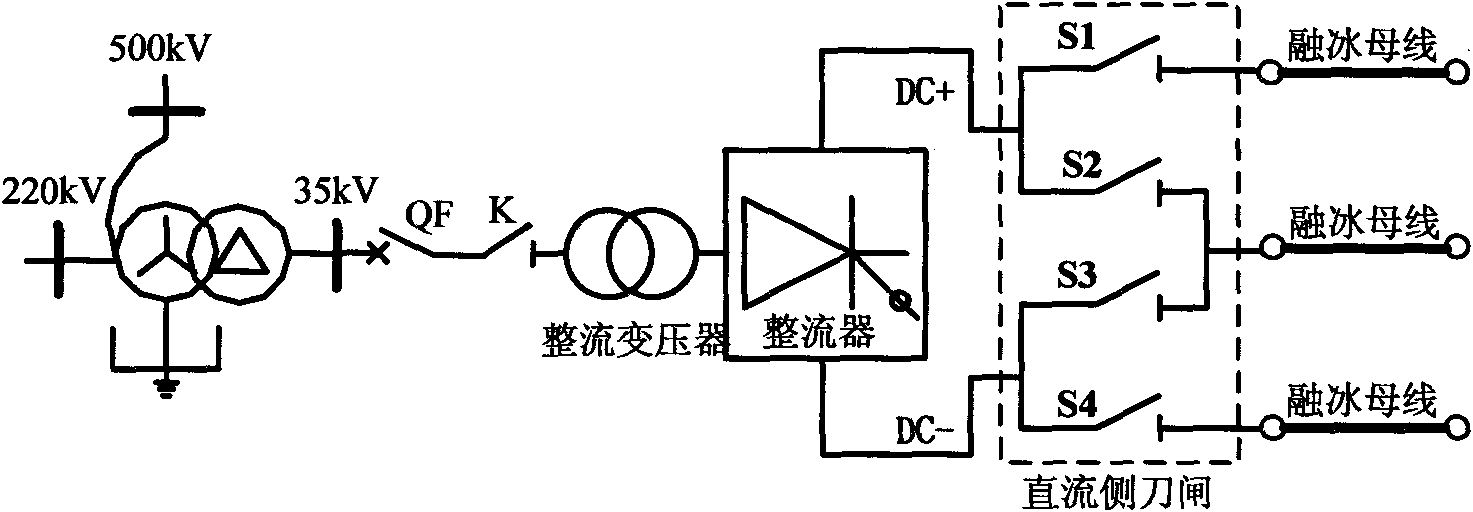

[0051] For the system commissioning diagram of the DC ice-melting device with a special rectifier transformer, see image 3 and Figure 4 . (1) Combined with the DC deicing device, use the substation to analyze and calculate the voltage level and system stability of various commissioning conditions by using the electromechanical transient simulation program, and formulate the accident plan. In the electromagnetic transient simulation program, an equivalent power supply model including the detailed control and protection functions of the DC deicing device is established, and the start-stop sequence of the DC deicing device, the filter switching strategy, control and protection functions and parameters, and the conversion of working conditions are tested, and The harmonics and reactive power of the DC deicing device under various working conditions are analyzed. (2) image 3 In the process, the DC side switch S1, S2, S3 and S4 are disconnected, the switch K is closed and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com