Device for descaling and derusting for pipeline and coating to form anti-corrosion coat and application method

A technology of anti-corrosion coating and cleaning device, which is applied in the direction of coating, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of affecting the flow rate of pipeline fluid, large pipeline wear and loss, etc., to ensure water quantity and quality, construction Fast progress, low-impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

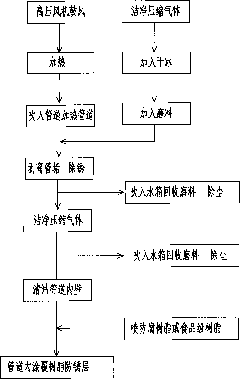

[0015] like figure 1 Shown, a kind of pipeline descaling derusting and coating anticorrosion coating device, comprises cleaning device and pipeline film coating device. The cleaning device is connected to the air storage tank 2 by the air outlet pipe of the oil removal and water filtration device 1 through the air pipe, and the compressed air generated by the air compressor 1 is purified and stabilized. The bin 5 is connected to the jet generating pipe 4 through the dry ice control valve 15 and the downstream tee, and a jet is generated in the jet generating pipe 4 to mix the dry ice into the compressed air, and enter the pipeline 10 to be cleaned through the pipe joint 13, and the abrasive storage bin 6 passes through The abrasive control valve 16 and the downstream tee are connected to the jet generating pipe 4, and a jet is generated in the jet gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com