Method for folding corner of box for packing welding wire

A folding method and cardboard box technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as large space and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] (precondition)

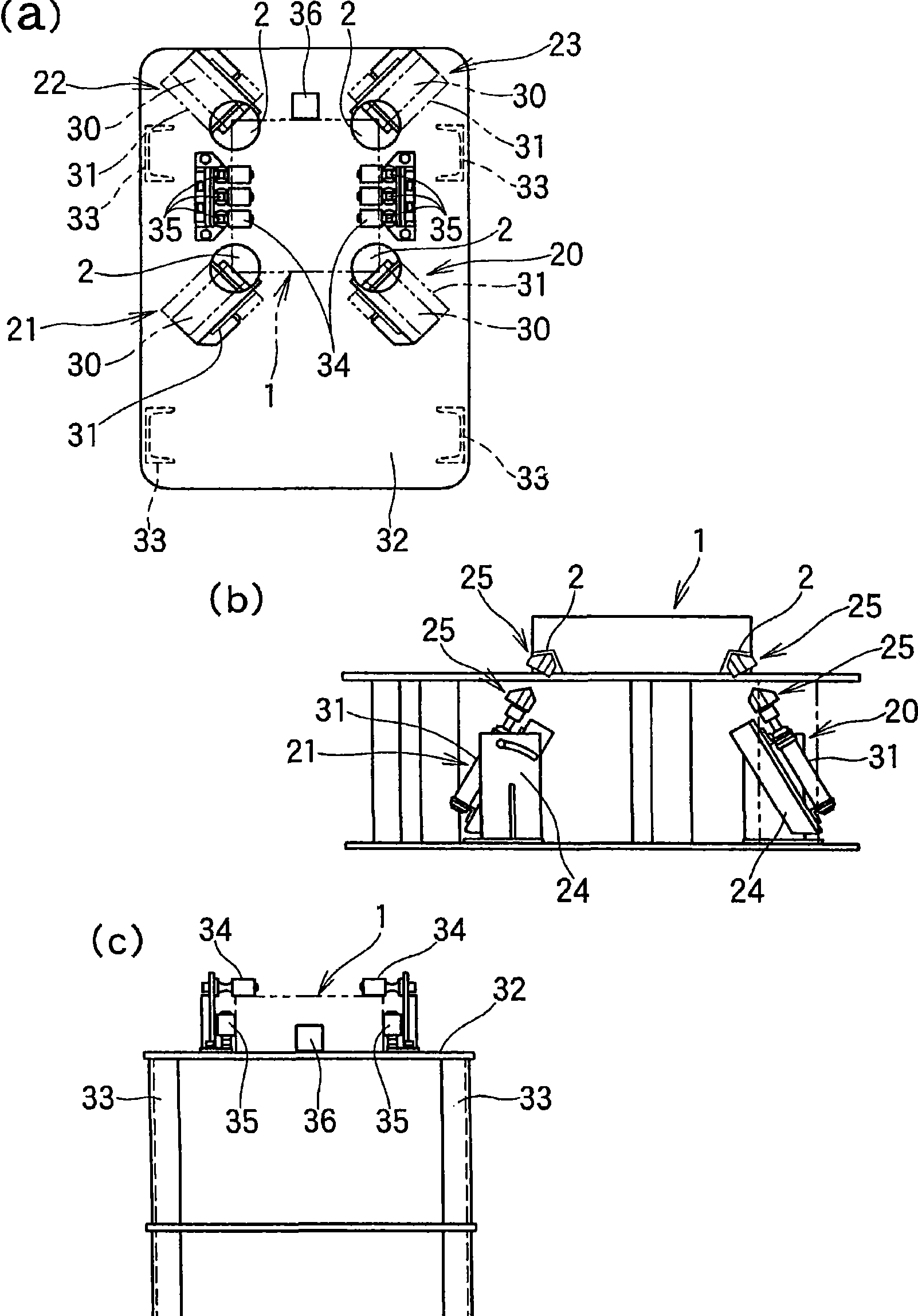

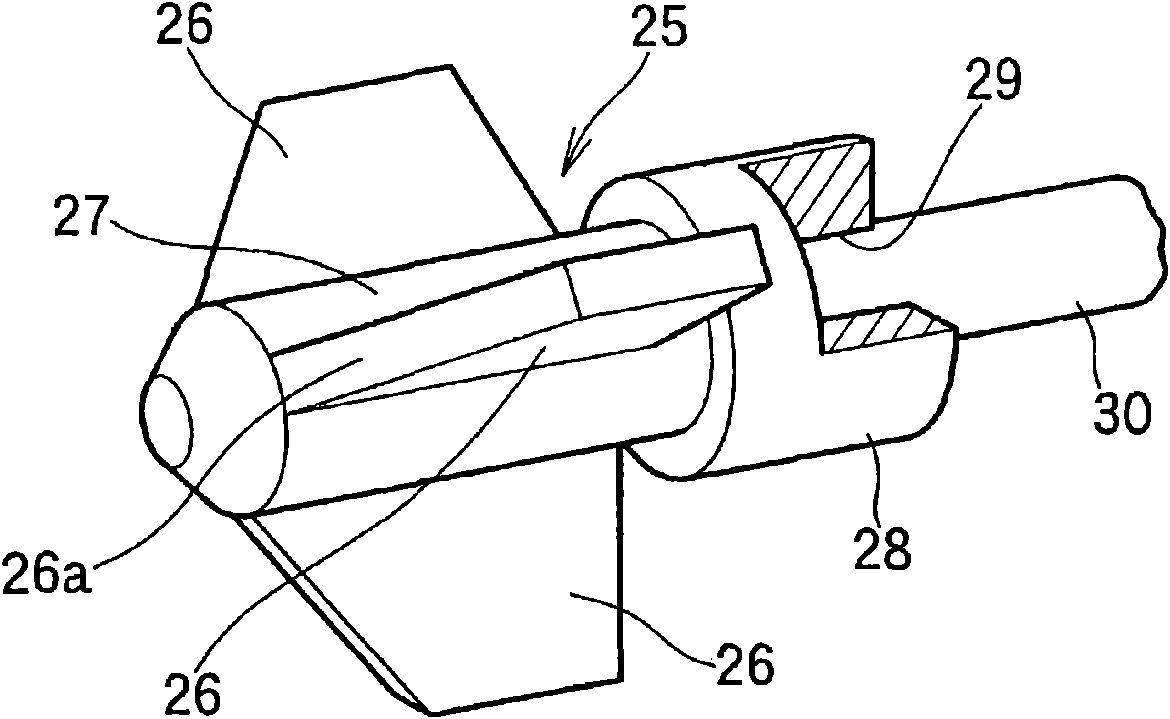

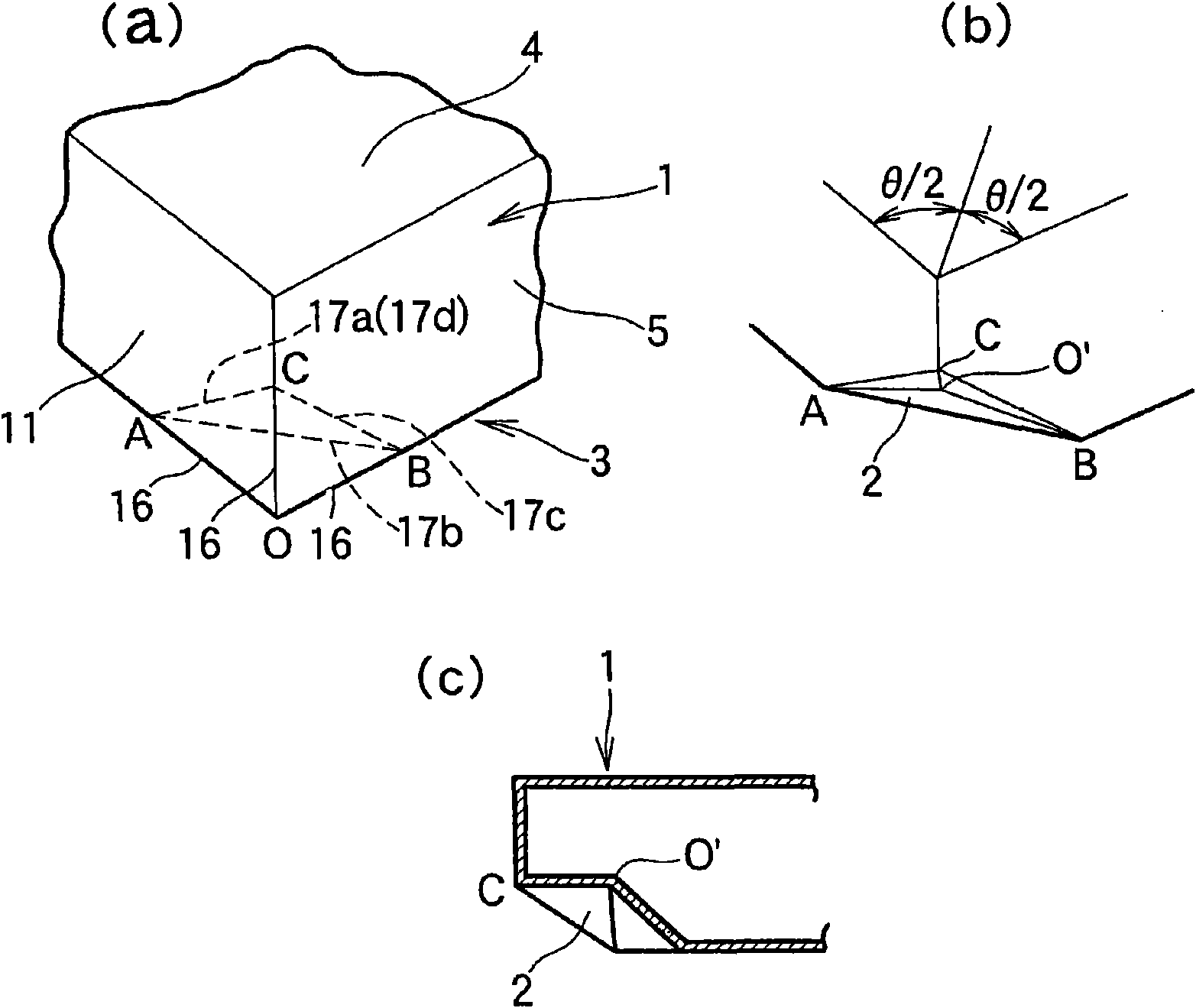

[0036] The folding method of the present invention, as a premise, is aimed at corner folding, the assembly structure of the packaging cardboard box for welding wire, the unfolded structure of the original cardboard before being assembled into a box shape, and the folding method of the folding line are the same as the Japanese patent. The contents of Kaiping No. 5-262346 and Teping No. 7-115431 are the same. i.e. packing cartons1, according to Figure 3 to Figure 7 As shown, there are at least two recesses 2 provided at corners where three ridges gather, and each recess 2 is bent inward by three fold lines connecting the ridges 17 to form a cuboid. Specifically, the four corners of the lower surface of the packaging cardboard box 1 are bent inward to form the recess 2 . The concave portion 2 is formed by chamfering the corner of the rectangular parallelepiped box 1 with a plane, and after shaving off a right-angled triangular pyramid, then forming a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com