Treatment method of wet method zinc smelting by-products

A technology of hydrometallurgical zinc smelting and treatment method, which is applied in the fields of comprehensive utilization of non-ferrous metal resources and environmental protection, can solve the problems of many secondary materials, long treatment period, complicated treatment process, etc., and achieves favorable conductivity and simplified subsequent treatment. process, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

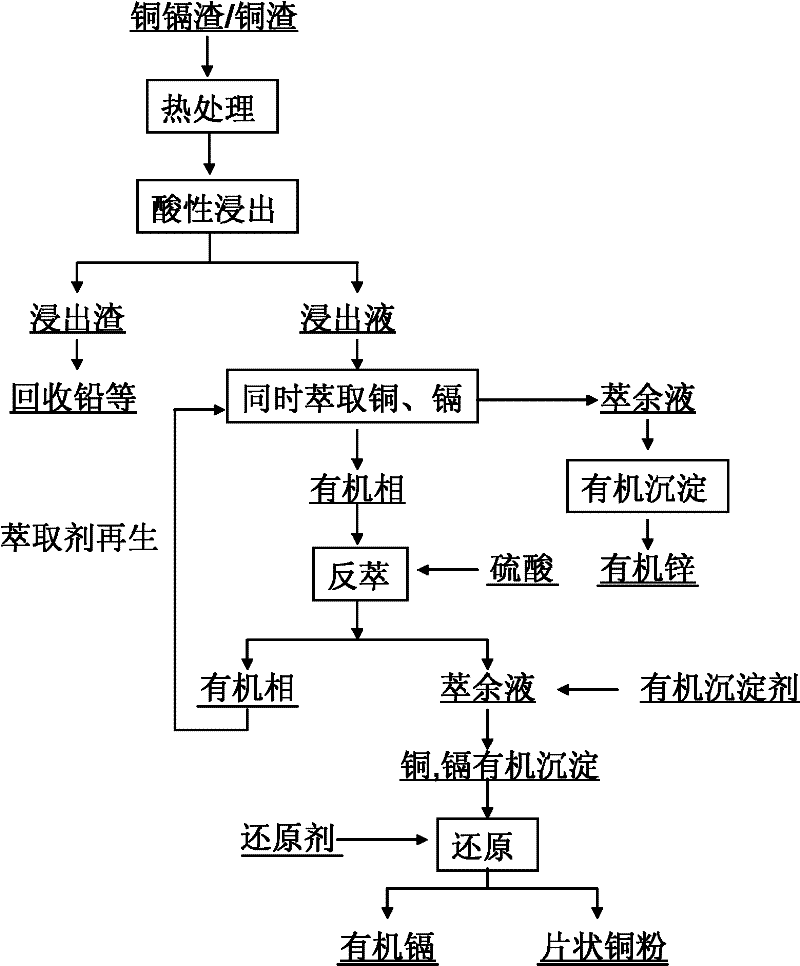

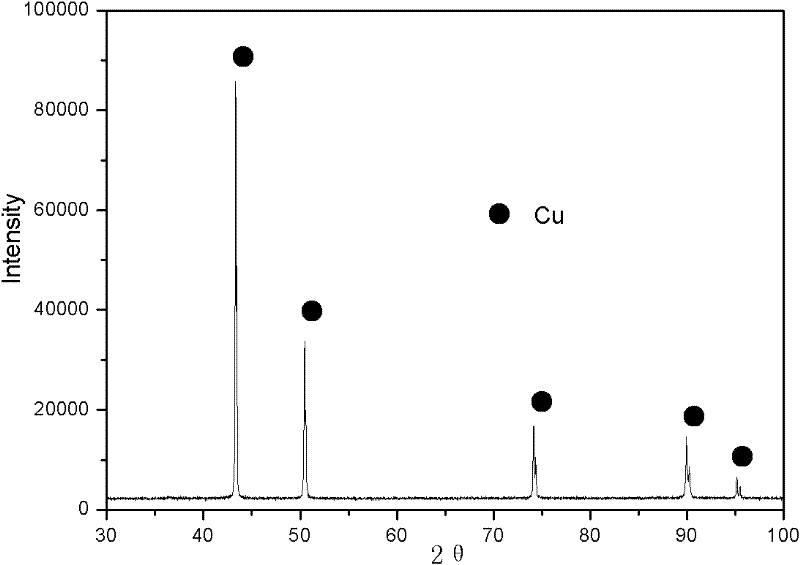

[0026] This example provides a treatment method for the by-products of zinc hydrometallurgy. Sulfuric acid solution is used to leach heat-treated copper and cadmium slag, and then extract copper and cadmium from the leaching solution with an organic solvent extraction method to obtain an organic phase rich in copper and cadmium. and raffinate containing zinc sulfate. The organic phase rich in copper and cadmium is back-extracted with sulfuric acid to obtain a mixed solution of copper sulfate and cadmium sulfate, and then an appropriate amount of organic precipitant is added to the mixed solution to obtain a mixture of organic precipitation of copper and cadmium. After the copper and cadmium precipitates are separated and washed, a reducing agent solution is added to carry out a reduction reaction to obtain flake copper powder and organic cadmium products respectively. The raffinate containing zinc sulfate is added with an organic precipitant to obtain organic zinc.

[0027] S...

Embodiment 2

[0029]This embodiment provides a treatment method for the by-products of zinc hydrosmelting. First, copper slag, one of the by-products of hydrosmelting, is heat-treated in a rotary kiln, and then copper and cadmium are simultaneously extracted from the leachate by organic solvent extraction. A copper-rich, cadmium-rich organic phase and a raffinate containing zinc sulfate are obtained. The organic phase rich in copper and cadmium is back-extracted with sulfuric acid to obtain a mixed solution of copper sulfate and cadmium sulfate, and then an appropriate amount of organic precipitant is added to the mixed solution to obtain a mixture of organic precipitation of copper and cadmium. After the copper and cadmium precipitates are separated and washed, a reducing agent solution is added to carry out a reduction reaction to obtain flake copper powder and organic cadmium products respectively. The raffinate containing zinc sulfate is added with an organic precipitant to obtain organ...

Embodiment 3

[0032] This example provides a treatment method for the by-products of zinc hydrosmelting. First, heat-treat the copper cadmium slag, one of the by-products of hydrosmelting, in a rotary kiln, and then extract copper and cadmium from the leachate simultaneously by using an organic solvent extraction method. , to obtain a copper-rich, cadmium-rich organic phase and a raffinate containing zinc sulfate. The organic phase rich in copper and cadmium is back-extracted with sulfuric acid to obtain a mixed solution of copper sulfate and cadmium sulfate, and then an appropriate amount of organic precipitant is added to the mixed solution to obtain a mixture of organic precipitation of copper and cadmium. After the copper and cadmium precipitates are separated and washed, a reducing agent solution is added to carry out a reduction reaction to obtain flake copper powder and organic cadmium products respectively. The raffinate containing zinc sulfate is added with an organic precipitant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com