Quick template supporting construction method of elevator shaft

A construction method and elevator shaft technology, applied in the direction of formwork/formwork/work frame, building structure support, building structure support, etc., can solve the problems of high labor intensity, unsafe work, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

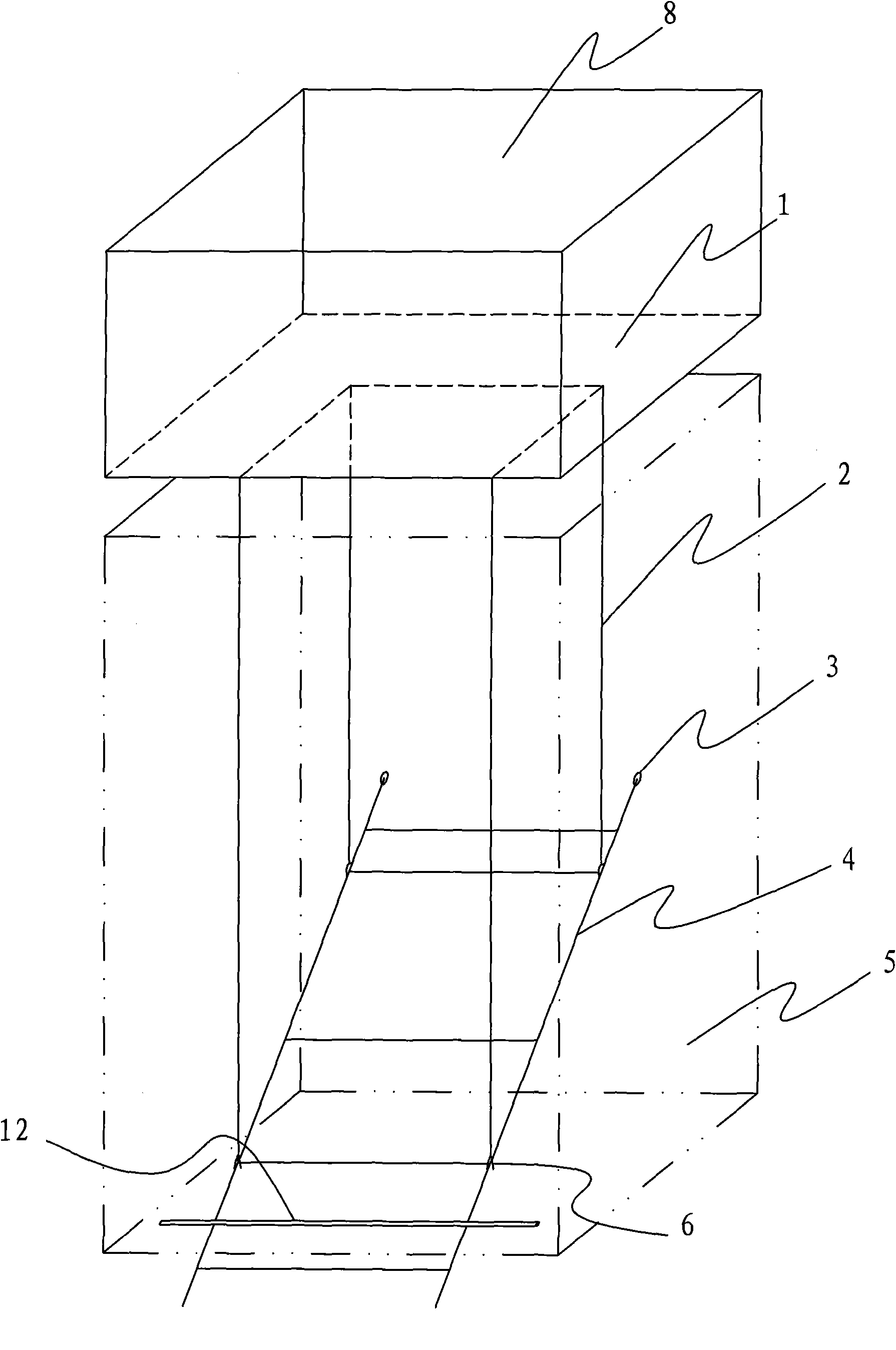

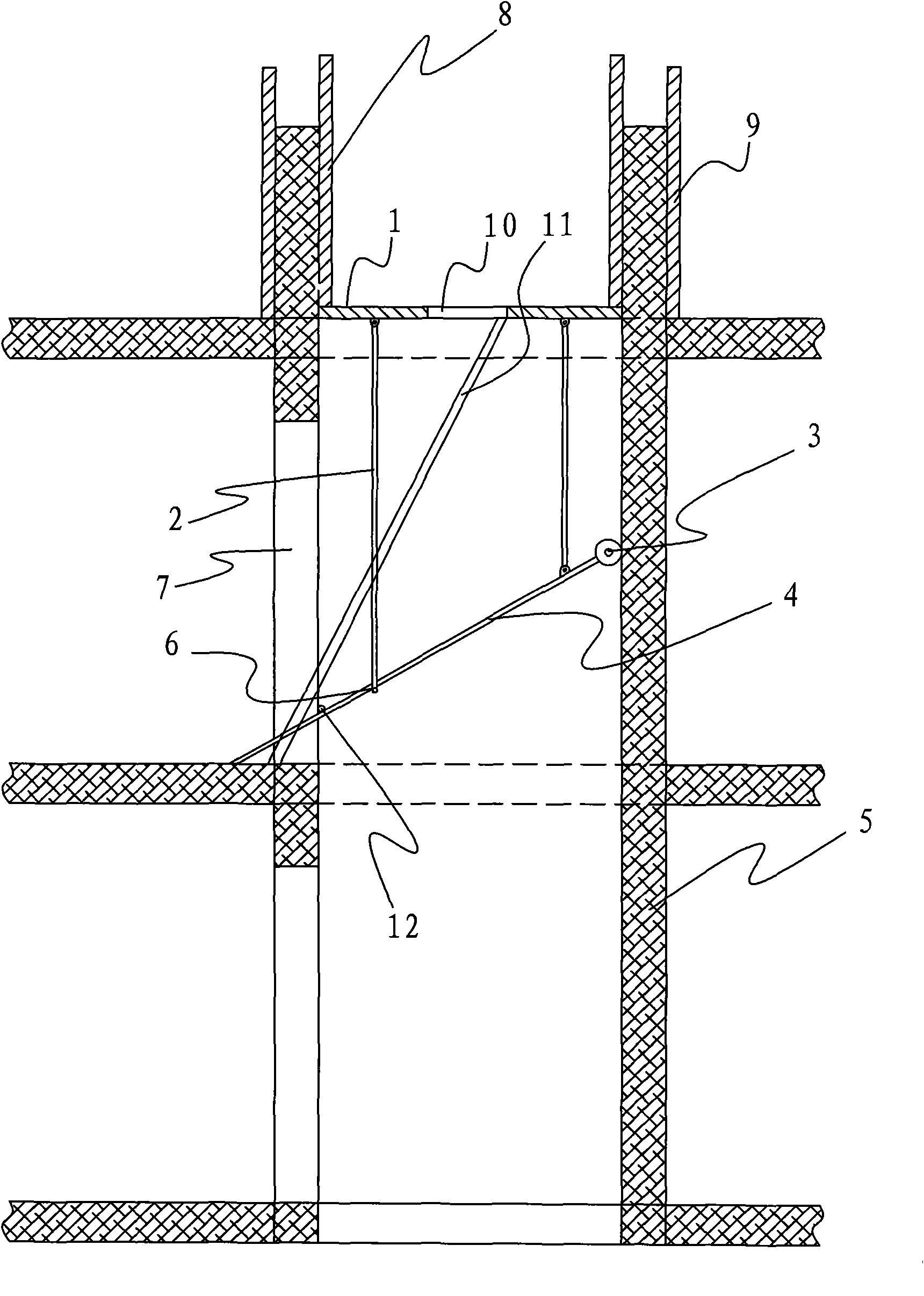

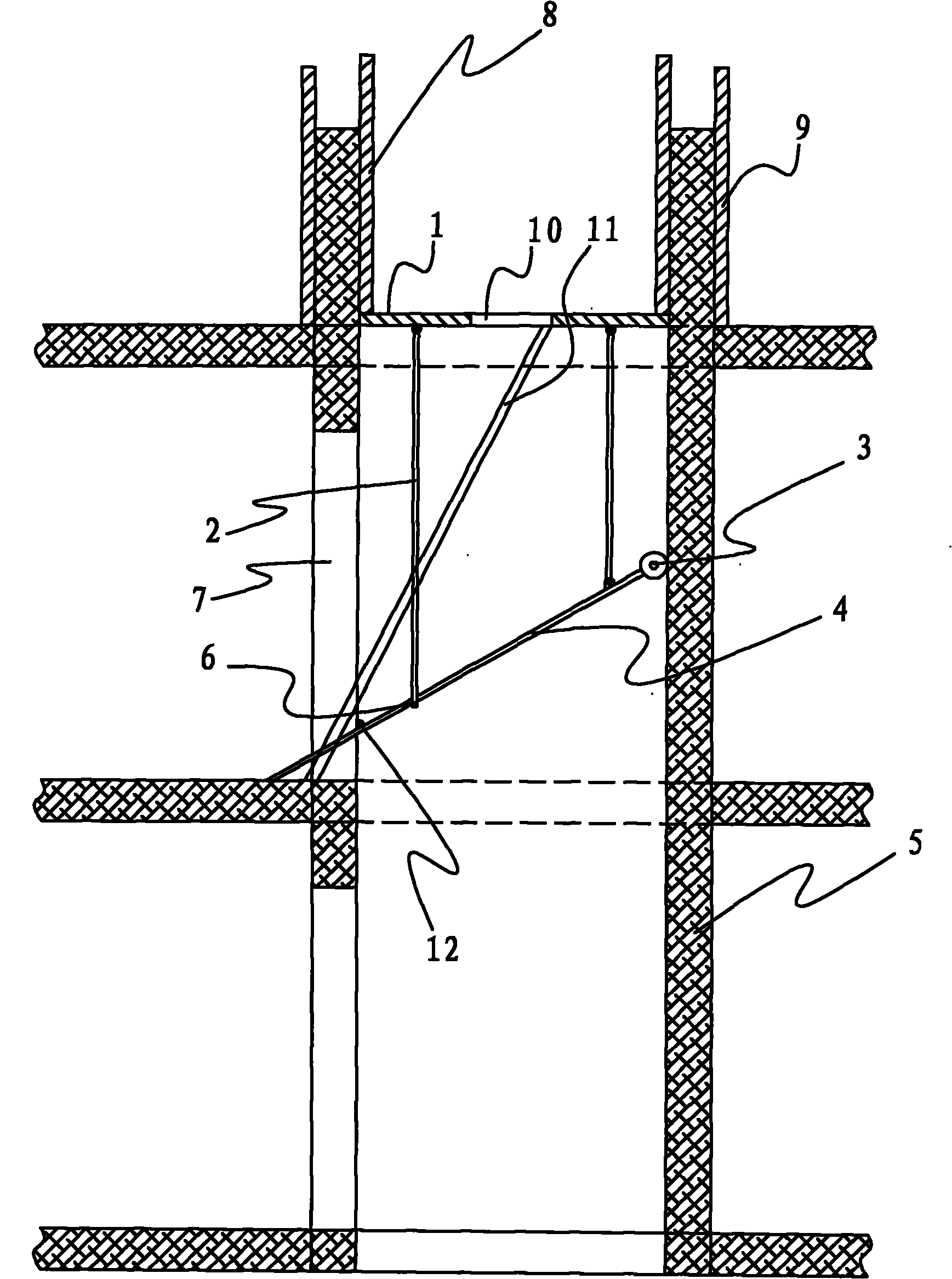

[0009] A kind of fast formwork construction method of elevator shaft, such as figure 1 , figure 2 As shown, first a support frame is constructed in the bottom of the elevator shaft 5, which is composed of a bottom stretcher 4 arranged obliquely, a middle column 2 and a top workbench 1.

[0010] In order to facilitate the construction personnel to enter the top working platform 1 from the elevator door on the next floor, an opening 10 with a cover plate can be set at the center of the top working platform 1, and a ladder 11 is placed in the opening 10. The ladder The lower end of 11 builds on the elevator door place of next floor, and after the construction of next floor is finished like this, builder can climb on the top working platform 1 by ladder 11, thereby makes things convenient for builder to enter and exit work.

[0011] The size of the top workbench 1 matches the size of the elevator shaft 5, and the lower end of the bottom stretcher 4 is against the elevator door. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com