Kitchen ventilation system and control method

A technology for ventilation systems and kitchens, applied in the field of ventilation systems, can solve problems such as damage to baffles and valves, energy waste, and increased power consumption of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Example 1 of Kitchen Ventilation System

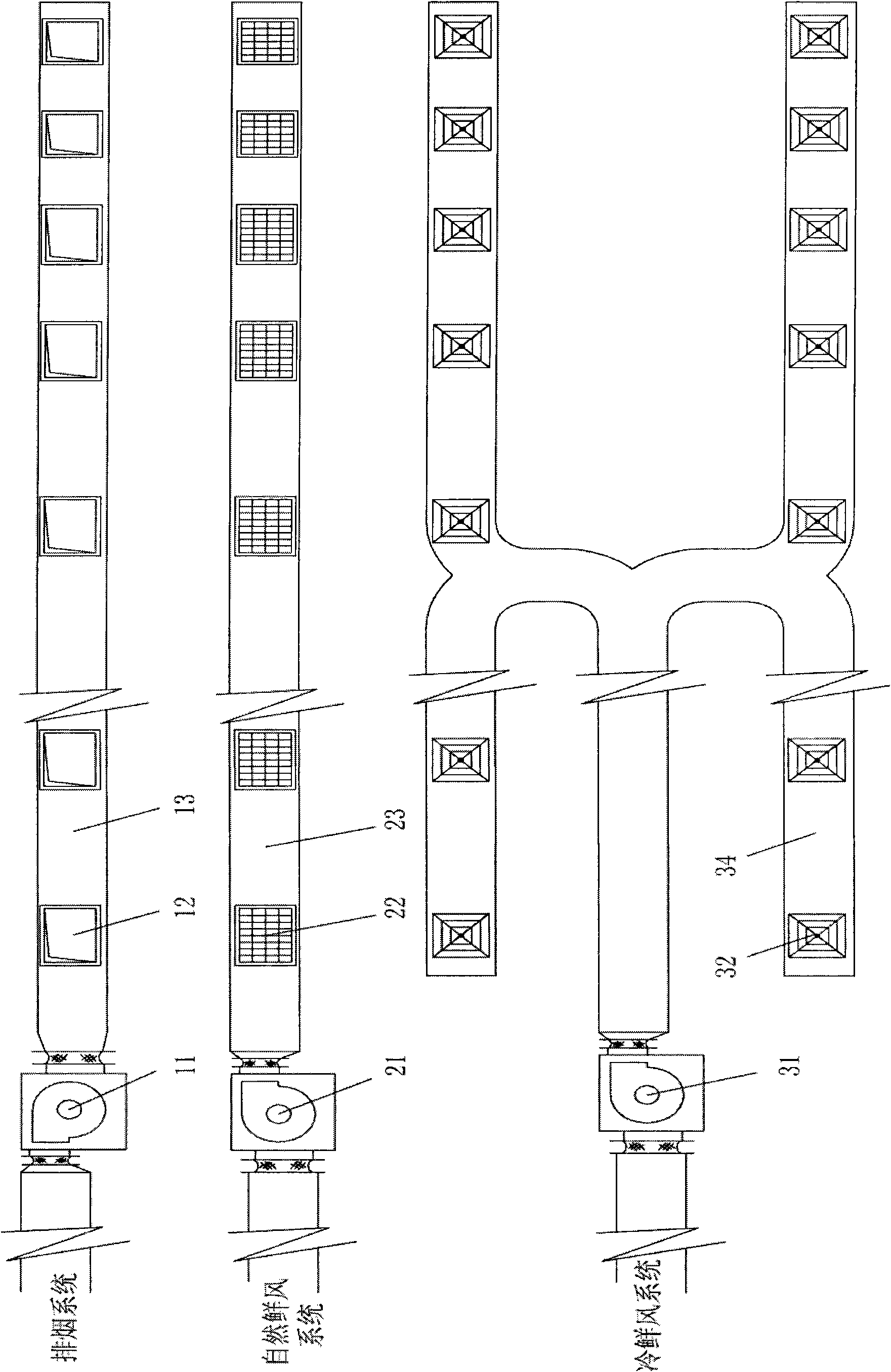

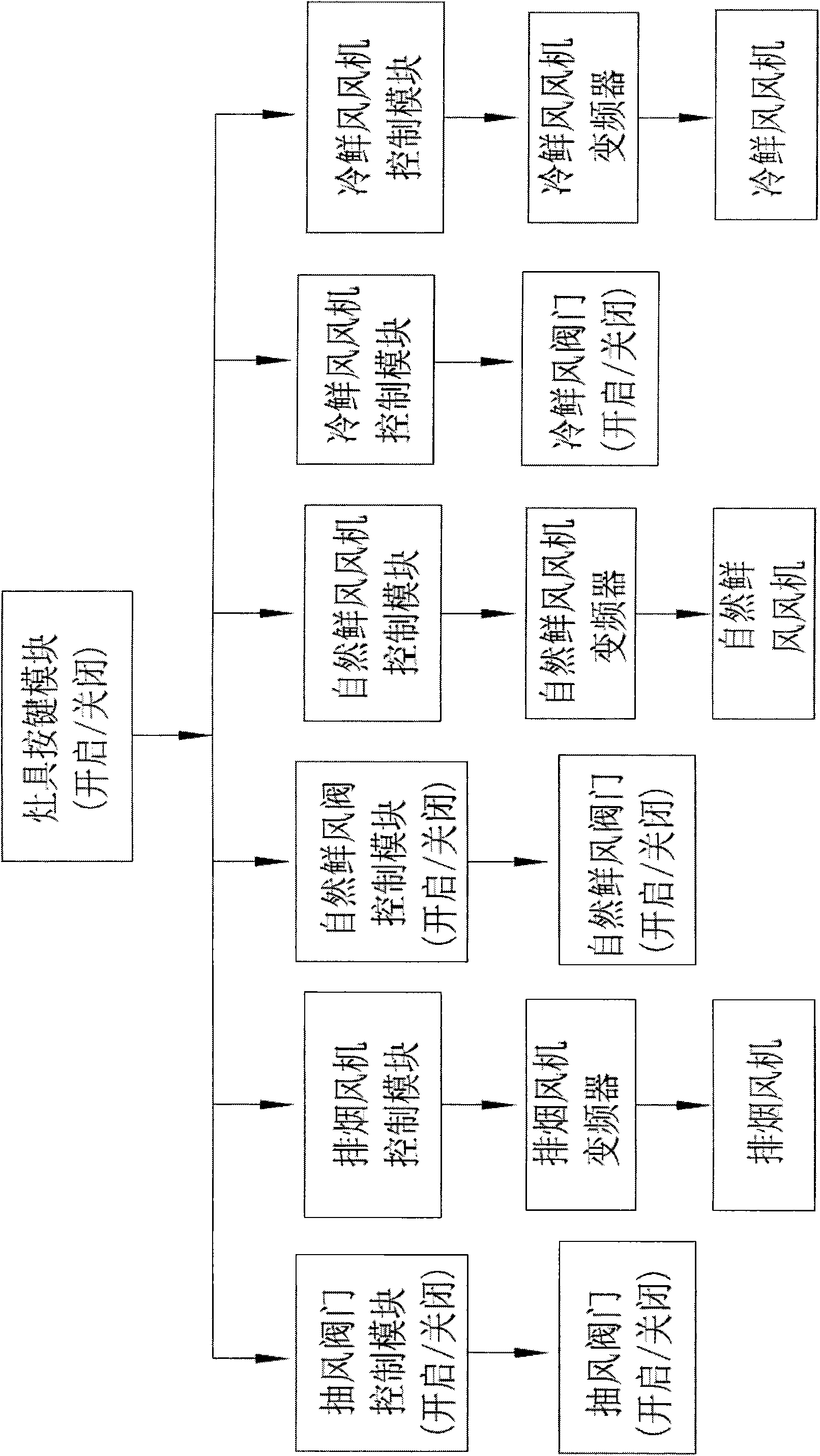

[0050] Such as figure 1 , figure 2 As shown, the kitchen ventilation system of the present invention includes a smoke exhaust system, a natural fresh air system, a cold fresh air system and a cooker button module.

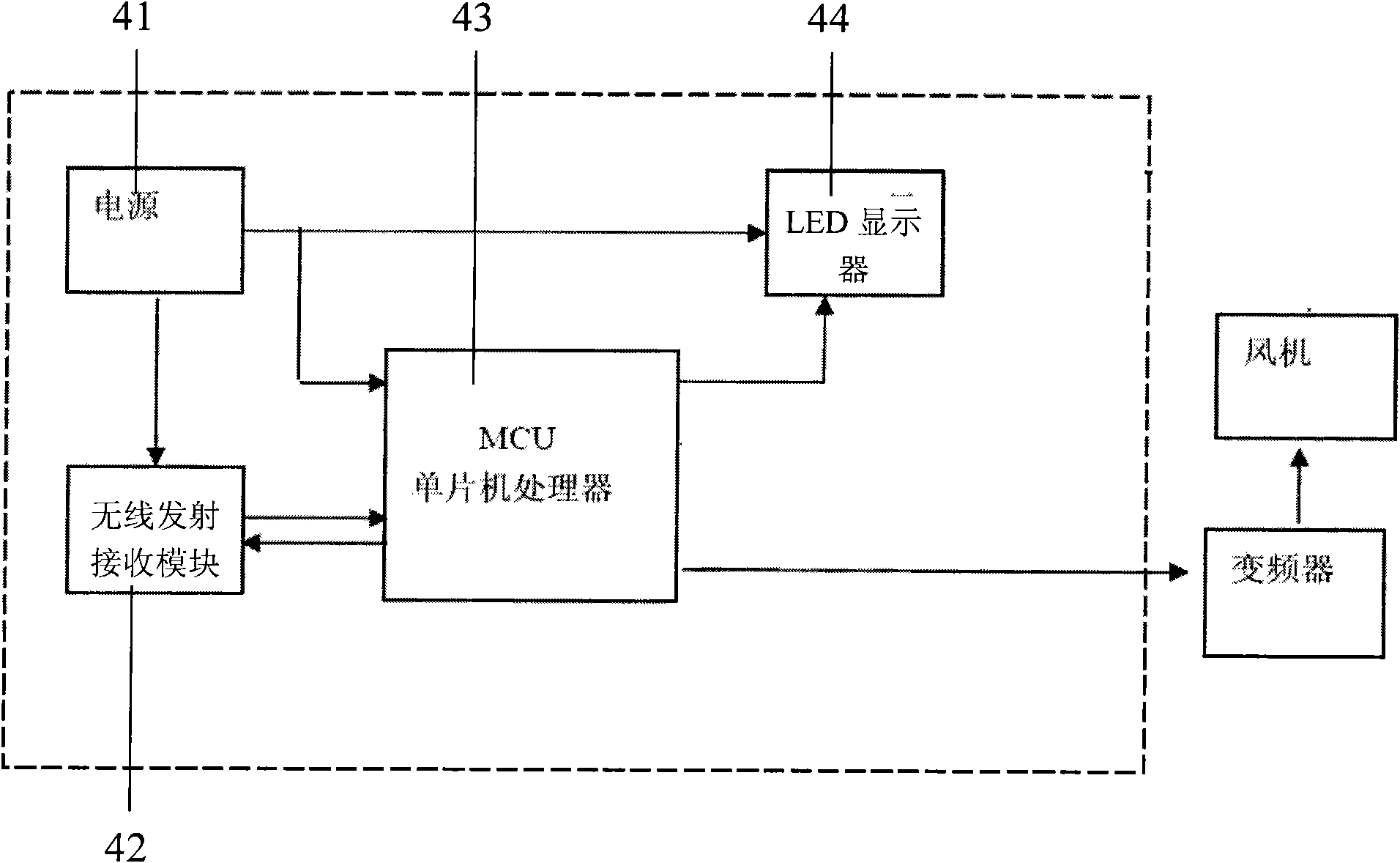

[0051] The smoke exhaust system includes a smoke exhaust flue 13, an exhaust valve 12 arranged at each exhaust point on the smoke exhaust flue 13, a smoke exhaust fan 11 arranged at the air outlet of the smoke exhaust flue 13, a smoke exhaust fan control module, and an exhaust valve control module. modules and frequency converters for smoke exhaust fans. The input end of the smoke exhaust fan inverter is connected to the power supply, and the output end is connected to the input end of the smoke exhaust fan to realize speed regulation. The smoke exhaust fan control module is connected to the smoke exhaust fan inverter by wire to realize speed regulation control. Signal connection refers to the connection of sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com