Multi-camera combination based method for online measuring engine cylinder combination face hole group

An engine cylinder block and measurement method technology, applied in the field of visual inspection, can solve problems such as difficulty in meeting the automatic, fast, and online inspection requirements of production lines, and the limitation of inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

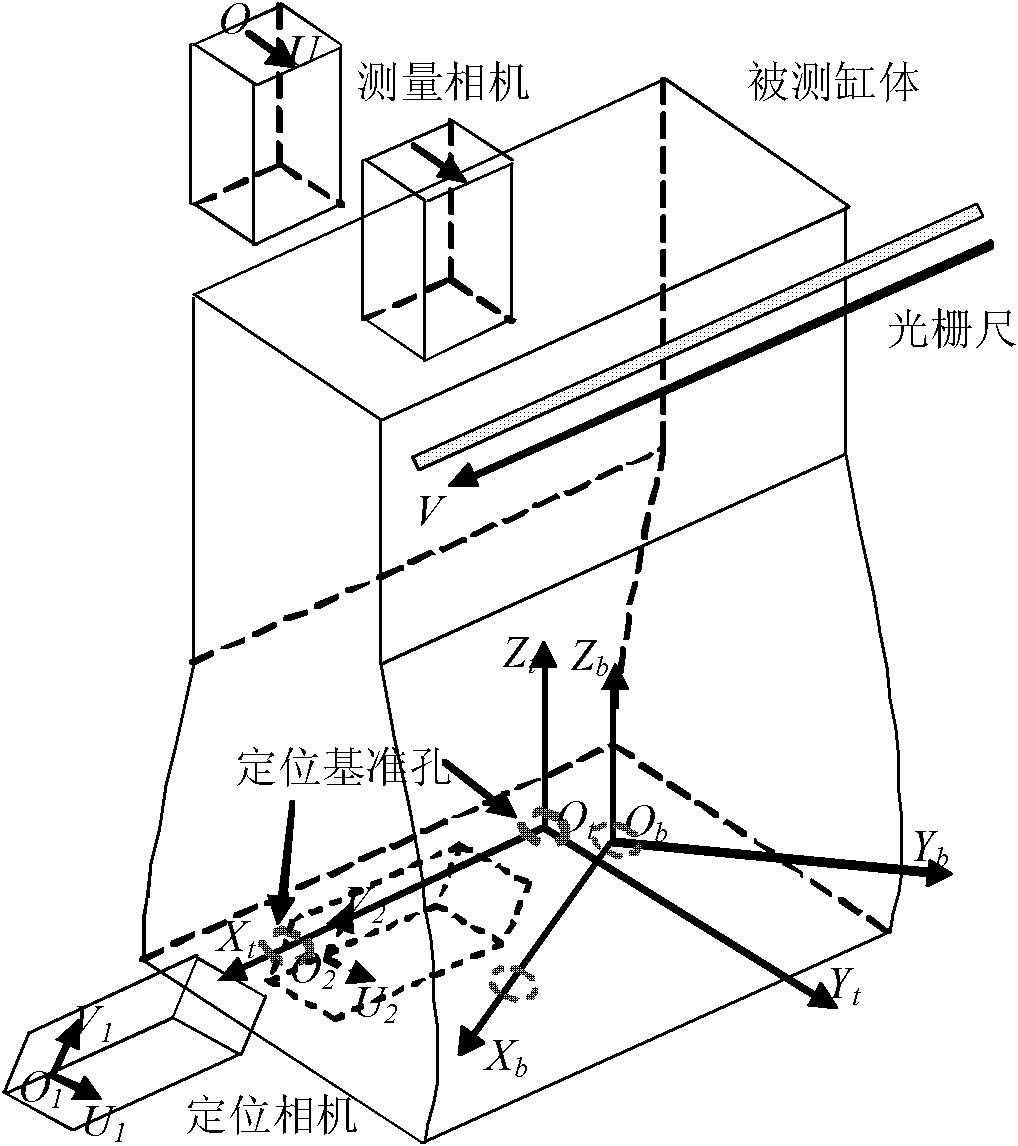

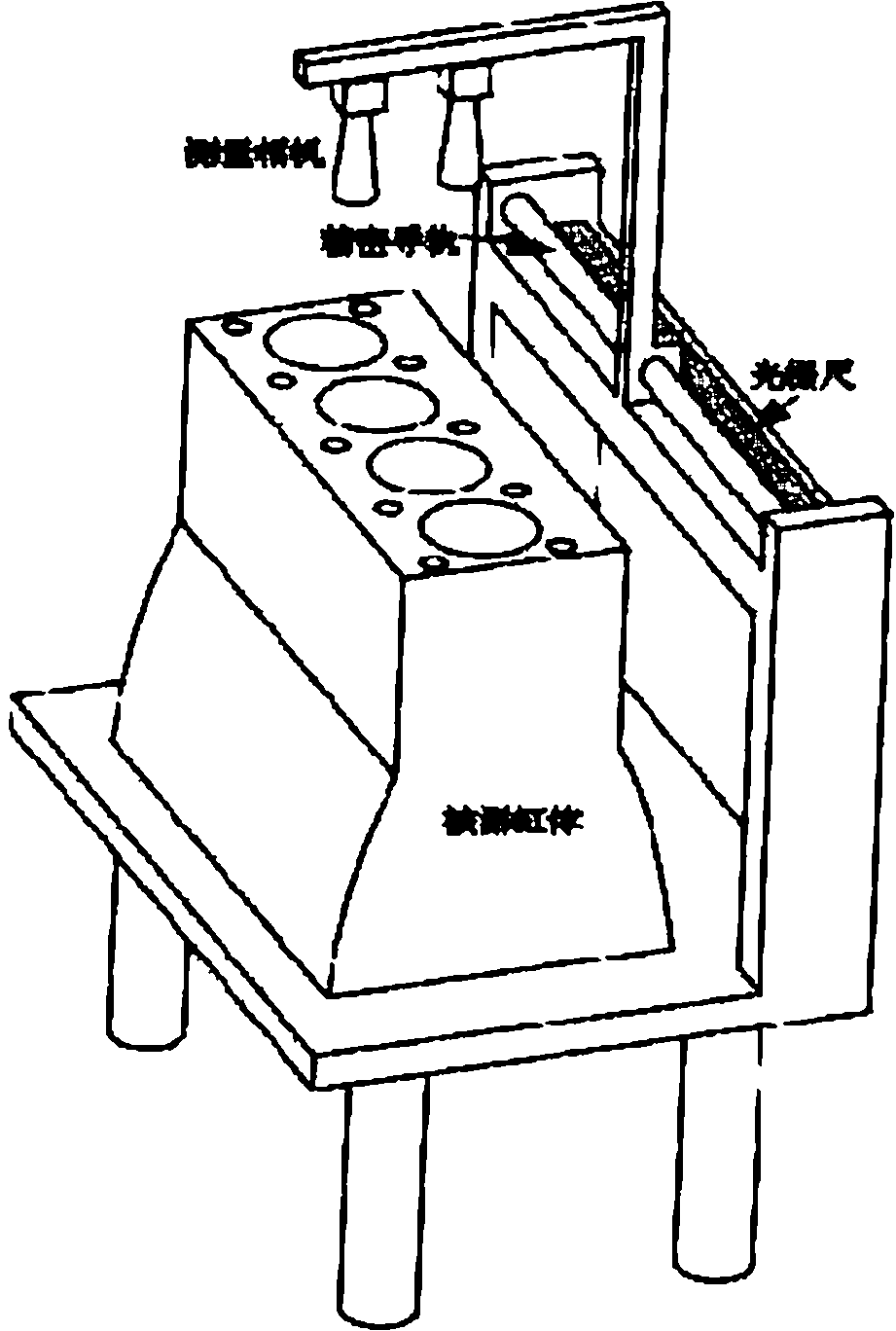

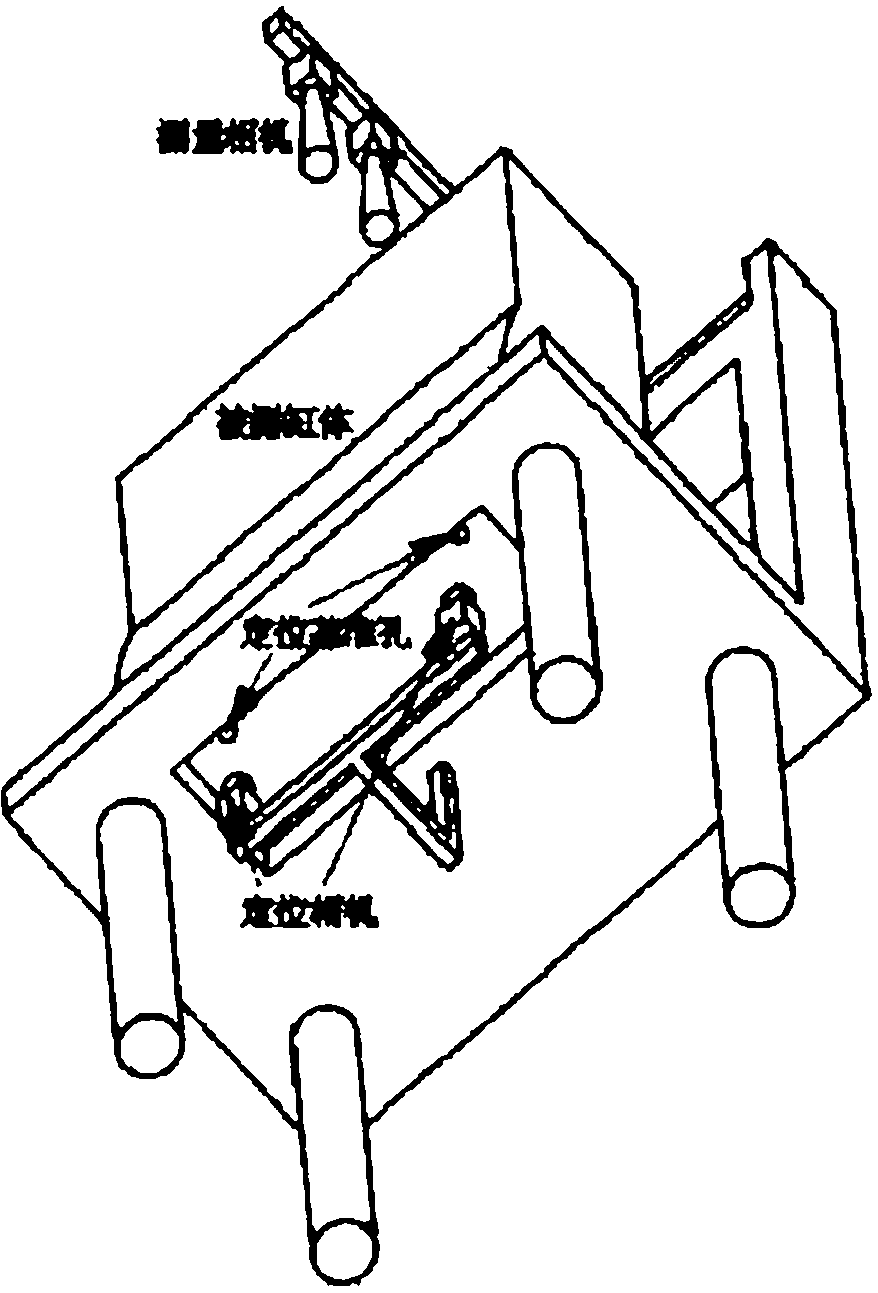

[0019] The measurement system designed by the present invention is composed of a linear array CCD measuring camera, an area array CCD positioning camera, a high-precision mechanical guide rail, a stepping motor drive system, a grating ruler, an LED lighting system, and a data processing computer. After the engine is positioned, the position of the two positioning holes on the bottom surface of the engine block is measured by the area array CCD positioning camera. The measurement coordinate system is established based on the two positioning holes on the bottom of the engine, and the linear array CCD measurement camera cooperates with the high-precision mechanical guide rail driven by the stepping motor to perform mechanical scanning to realize the image acquisition of the round hole of the engine block combined with the face group. The high-precision grating sensor performs synchronous measurement on the position of the line array CCD acquisition line, and finally obtains the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com