Automatic coconut cutting machine

An incision machine, automatic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

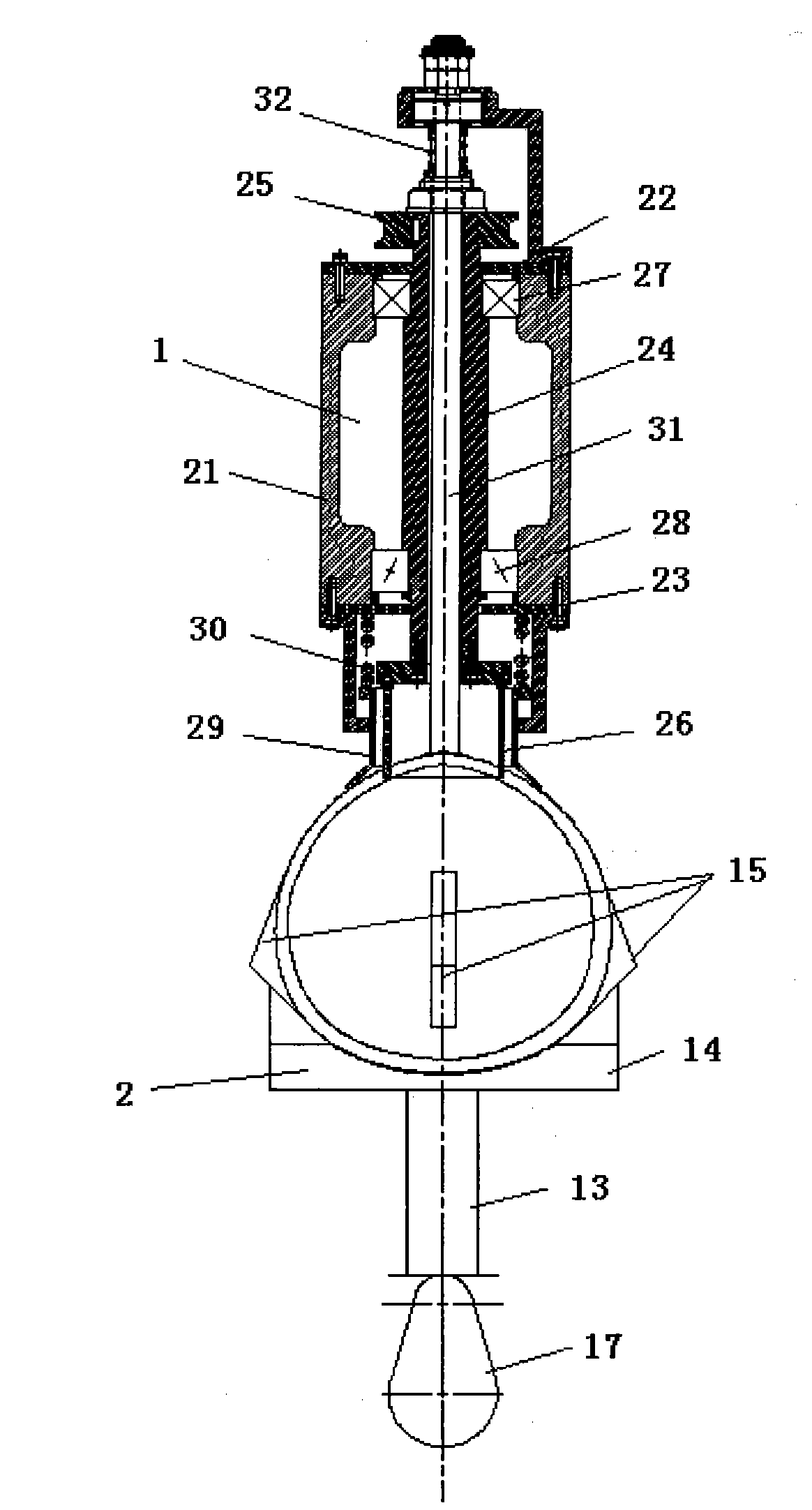

[0023] The above-mentioned compression sleeve 29 can be arranged on the inner side of the circular saw 26 or on the outer side. When being arranged on the inner side, after the cutting is completed, the compression sleeve 29 with the spring also has the function of ejecting the cut-off coconut shell cover simultaneously. But generally, the following preferred implementation mode will be taken: the compression sleeve 29 is arranged on the outside of the circular saw 26; on the inside of the circular saw 26, a ejector rod 31 is set through the hollow rotating shaft 24, and the ejector rod The upper end of 31 protrudes from the hollow rotating shaft, and a compression spring 32 is arranged between the support 21 .

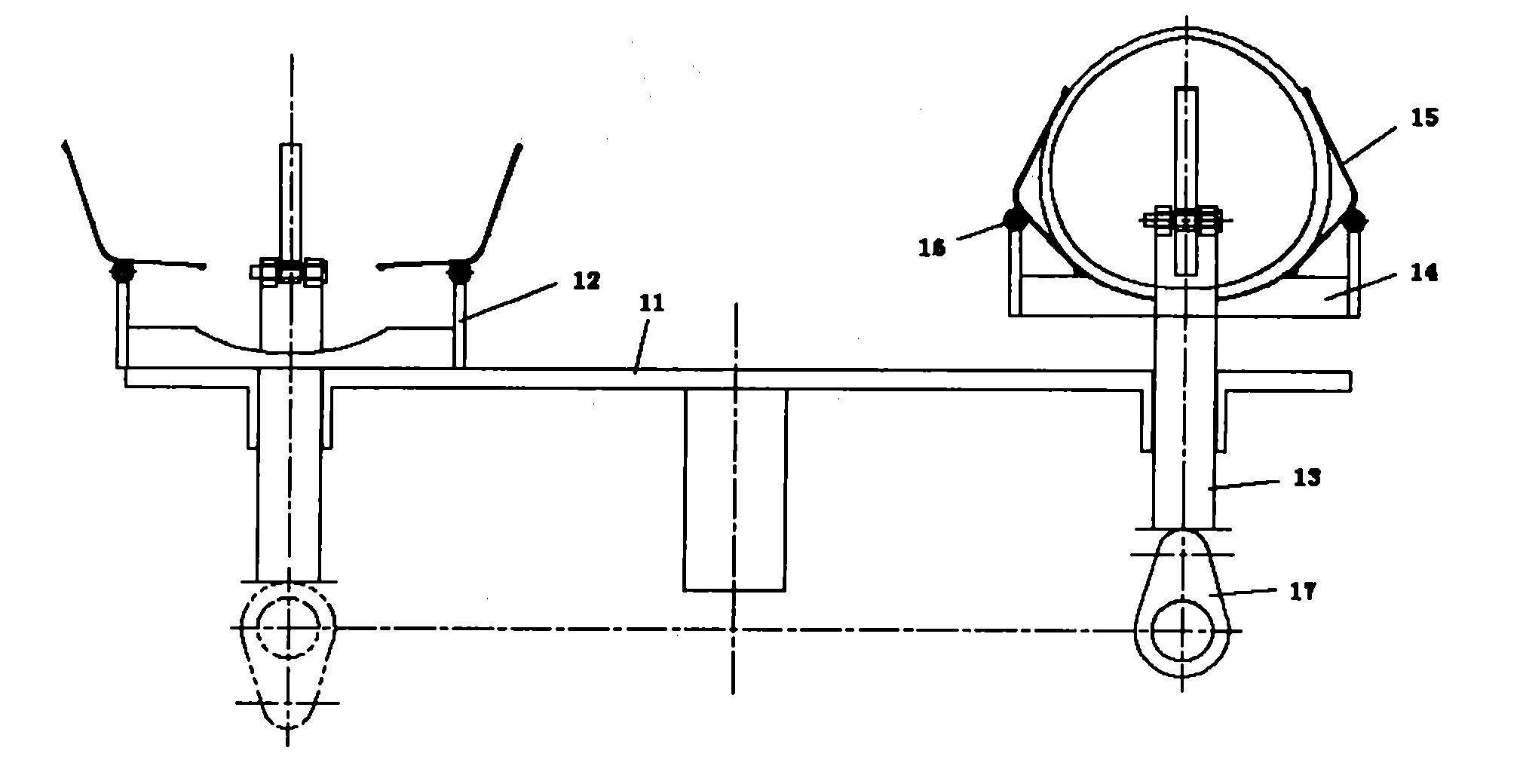

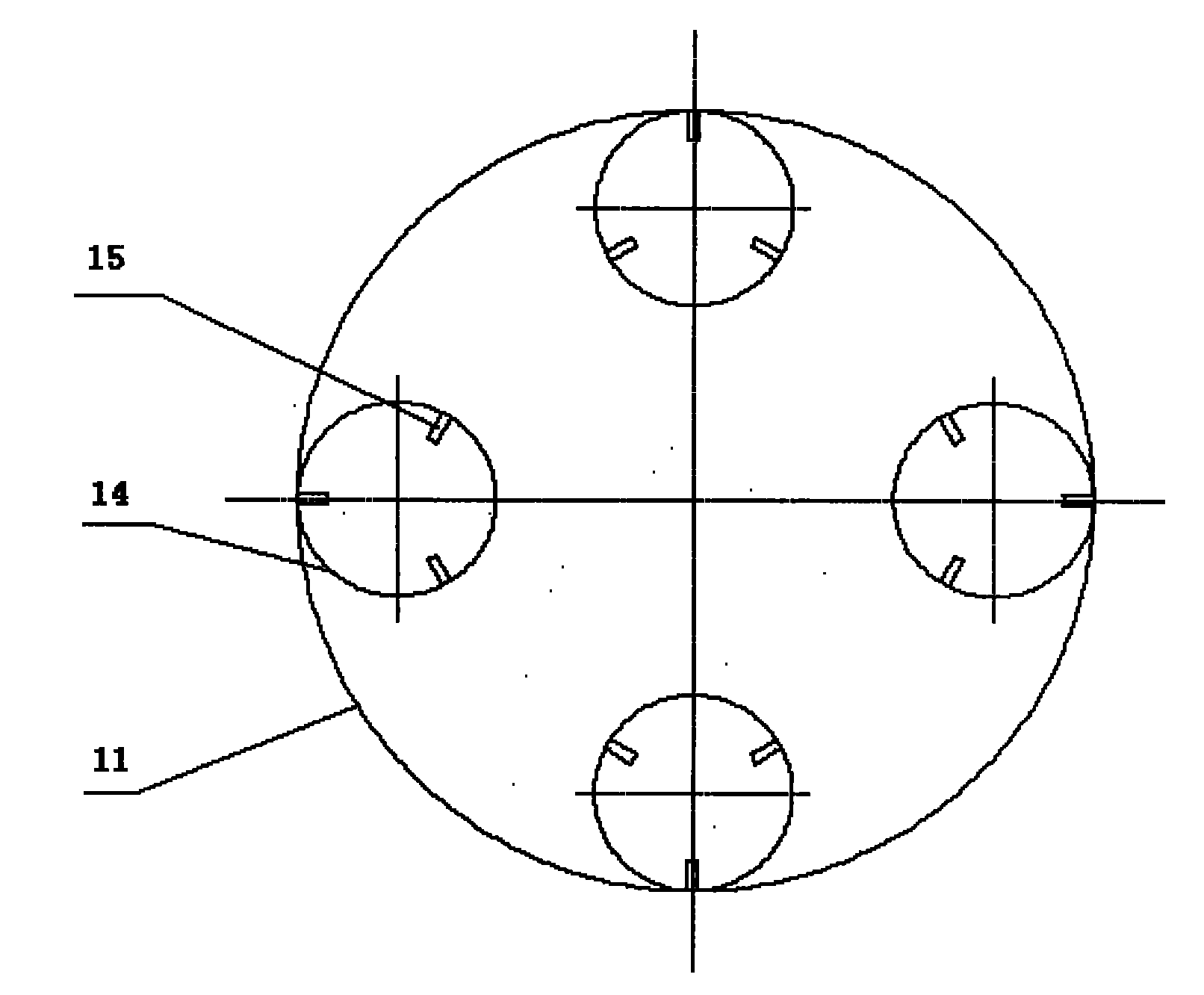

[0024] During work, at first manually will remove the coconut of coconut coat and put into the palm 14 of the manipulator on the workbench 11, drive workbench to rotate by transmission mechanism then, coconut is forwarded to the below of notch mechanism 2.

[0025] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com