Preparation method of high-performance lithium adsorbent

A lithium adsorption, high-performance technology, applied in chemical instruments and methods, lithium compounds, inorganic chemistry, etc., can solve the problems of uneven reaction and fast adsorption, and achieve the effect of sufficient reaction, fast adsorption and good adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

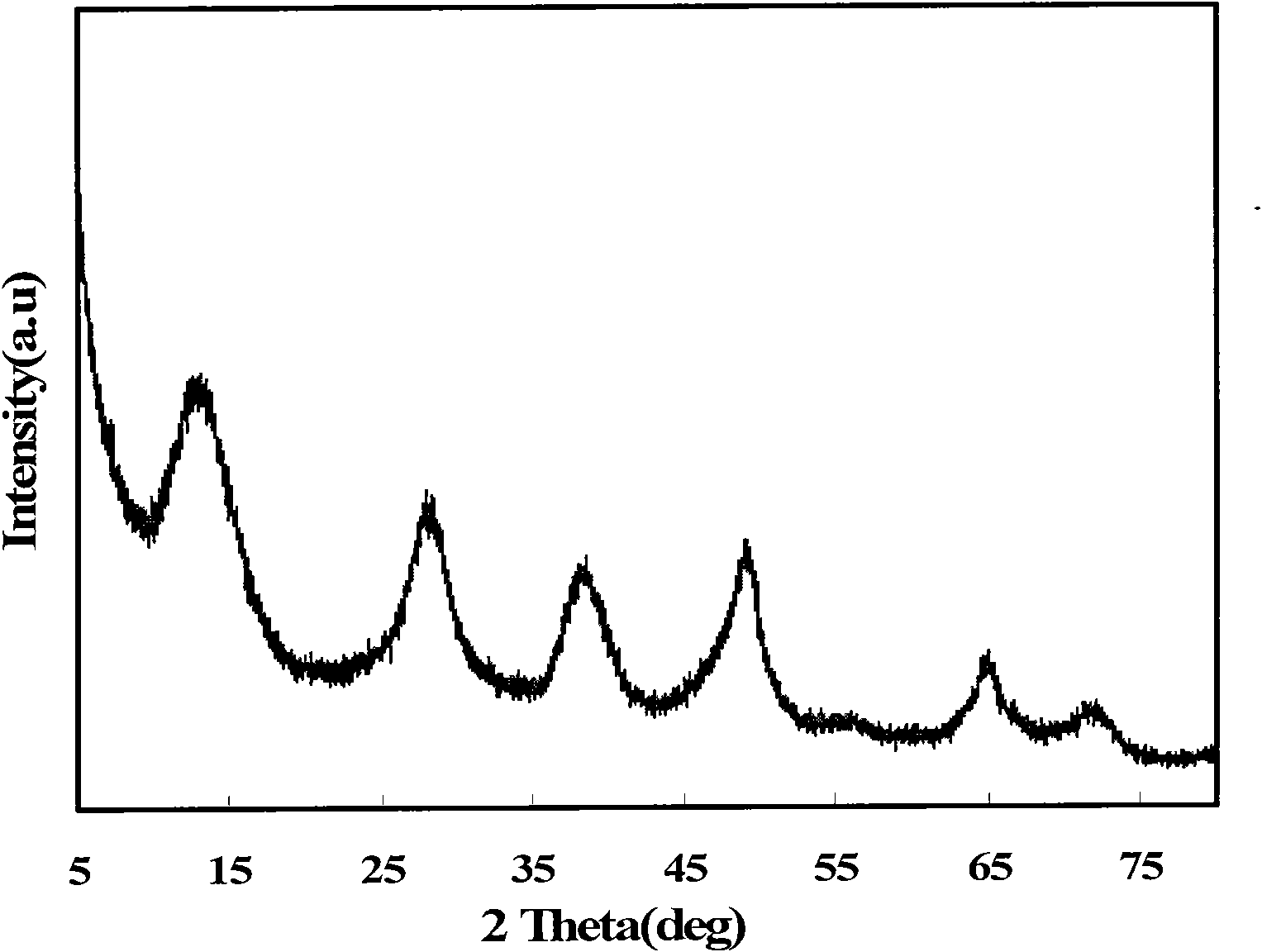

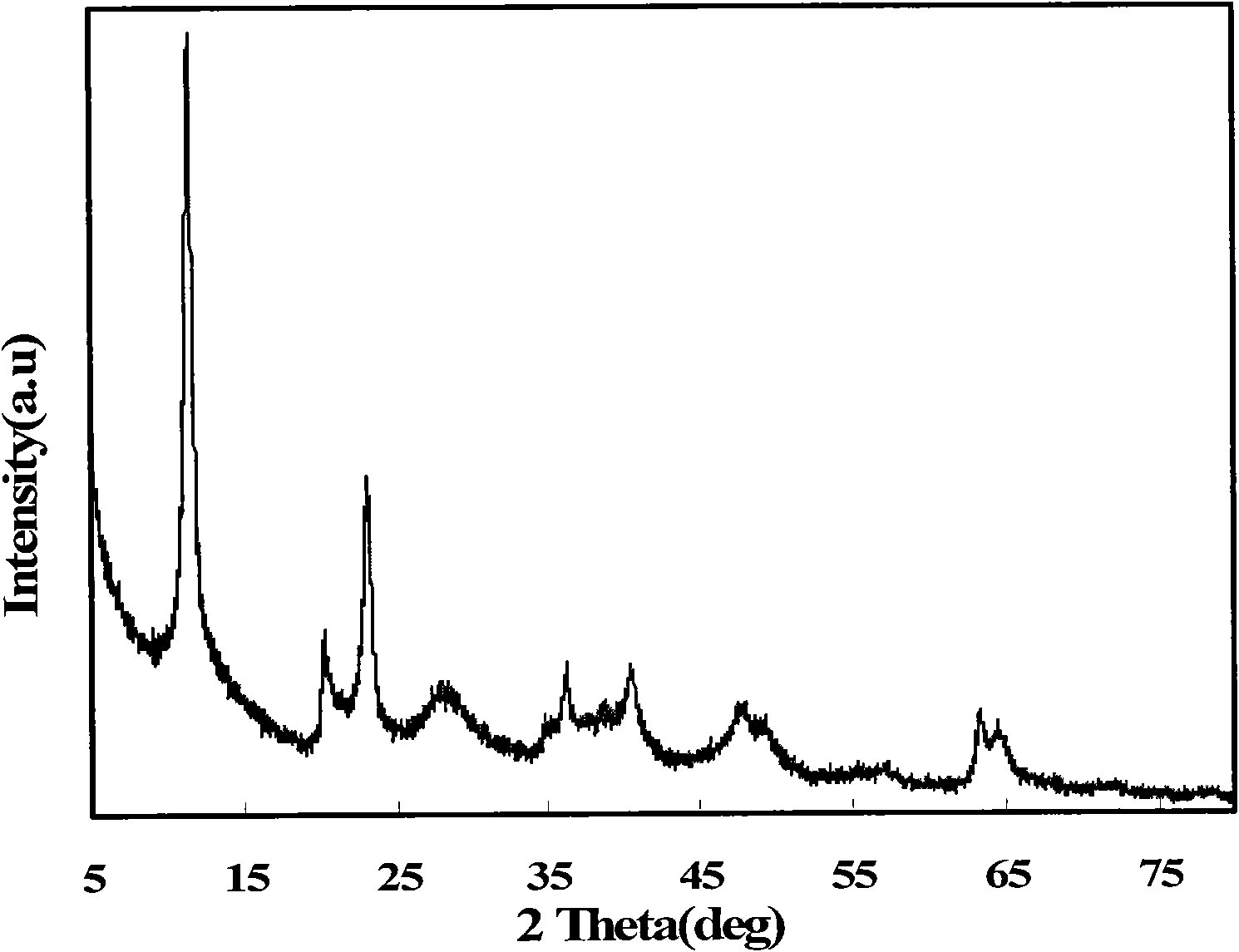

[0032] The preparation method of this high-performance lithium adsorbent of the present invention, the method comprises the following steps:

[0033] a. First add 100-500mL deionized water into a 1L three-neck flask, and adjust the pH to 3-7.

[0034] b. Grind large pieces of organoaluminum into powder to fully proceed with hydrolysis; add 25-150g of organoaluminum into a three-necked flask at 40-70°C, and hydrolyze at the above temperature to obtain active aluminum hydroxide. And after hydrolysis for 0.5h, add dropwise more than 3 times the lithium salt solution (or lithium salt solid) of organic aluminum, the concentration of lithium salt is 0.5-2mol / L, and the product obtained after reaction for 1-2h is LiCl 2Al(OH) 3 ·xH 2 O Active material: Active aluminum hydroxide is prepared by hydrolysis of organoaluminum, the hydrolysis temperature is 40-70°C, and the hydrolyzed product is active aluminum hydroxide. The organoaluminum is with -AlR 3 or Al(OR) 3 Group substances, ...

Embodiment 1

[0039] First, 100 mL of deionized water was added into a 1 L three-neck flask, and the pH was adjusted to 3. Heat to keep the water temperature at 50°C, add 25g of aluminum isopropoxide into it while stirring, after stirring for 0.5h, prepare 250mL of 1mol / L lithium chloride solution, add it dropwise to the above solution, control the reaction speed so that the lithium chloride The solution was added dropwise within 0.5h. After the reaction is over, continue to stir for 1 h to generate LiCl 2Al(OH) 3 ·xH 2 O. The above precipitate is filtered, washed with ethanol and dried to obtain the aluminum hydroxide active material product. The ethanol in the resulting filtrate can be used repeatedly after distillation.

Embodiment 2

[0041] First, 100 mL of deionized water was added into a 1 L three-necked flask, and the pH was adjusted to 4. Heat to keep the water temperature at 60°C, add 25g of aluminum isopropoxide into it while stirring, after stirring for 0.5h, prepare 500mL of 0.5mol / L lithium chloride solution, add it dropwise to the above solution, control the reaction speed so that the chlorine Lithium chloride solution was added dropwise within 0.5h. After the reaction is over, continue to stir for 1 h to generate LiCl 2Al(OH) 3 ·xH 2 O. The above precipitate is filtered, washed with ethanol and dried to obtain the aluminum hydroxide active material product. The ethanol in the resulting filtrate can be used repeatedly after distillation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com