A Subcritical Injection Method for Fat-Soluble Components

A subcritical, fat-soluble technology, applied in separation methods, chemical instruments and methods, fat production, etc., can solve the problems of easy destruction and volatilization of active ingredients, unsuitable for industrialized production, difficult maintenance, etc. The effect of destroying the activity of the product and reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

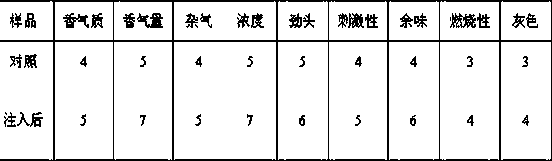

Embodiment 1

[0023] Take 30 g of Yunnan tobacco leaves, smash them through a 40-mesh sieve, and place them in a closed extraction tank. Take 500 g of BK31 low-order tobacco leaves and place them in the injection tank. Use a vacuum pump to make the extraction tank and injection tank reach the vacuum requirements and send them to the extraction tank. Inject 900mL of butane into the medium and completely immerse the Yunnan tobacco leaves. The soaking time is 30 minutes, the temperature is 40℃, the pressure is 0.6 MPa, and the extraction is performed 4 times. After the extraction, the liquid solvent is pumped into the evaporation tank, and the Yunnan tobacco leaves and the liquid solvent are separated. Perform constant temperature desolventization treatment, the liquid solvent desolves to obtain the extract containing the fat-soluble components of Yunnan tobacco leaves; the above subcritical fluid butane is pumped into the injection tank, the BK31 low-order tobacco leaves are completely submerged...

Embodiment 2

[0028] Granulate 200 g of fresh and dried red pepper, crush it through a 100-mesh sieve with a particle size of 2 mm, and place it in an extraction tank; take 500 g of natural fiber fabric and wind it on a distributor and place it in an injection tank; use a vacuum pump to make the extraction tank and The injection tank meets the vacuum requirement, and subcritical fluid dimethyl ether is injected into the extraction tank as the extraction solvent. The extraction solvent completely immerses the pepper particles. The mass-volume ratio of the pepper particles and the extraction solvent reaches 1:20 g / ml. The soaking time is 15 minutes, the temperature is 30°C, the pressure is 0.55 MPa, and the extraction is repeated 3 times; after the extraction, the pepper particles and the liquid solvent are separately treated at a constant temperature, and the liquid solvent is removed to obtain an extract containing the fat-soluble components of the pepper particles; The above subcritical flui...

Embodiment 3

[0031] Take 150 g of sandalwood extract and dry it until the moisture content is below 4%. After crushing, pass a 50-mesh sieve and place it in the extraction tank, and put a whole 1 kg pear wood in the injection tank; use a vacuum pump to make the extraction tank It meets the vacuum requirement with the injection tank, and injects the subcritical fluid butane into the extraction tank as the extraction solvent. The extraction solvent completely immerses the sandalwood extract and then performs subcritical extraction. The mass volume ratio of sandalwood to extraction solvent is 1:10 g / ml, the extraction time is 10 minutes, the temperature is 35℃, the pressure is 0.1 MPa, and the extraction cycle is 3 times; after the extraction, the sandalwood and the liquid solvent are subjected to constant temperature desolvation treatment, and the liquid solvent desolves to obtain sandalwood grease. Extraction of soluble components; using the above subcritical fluid butane as an injection solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com