Water electrolysis hydrogen-oxygen flame welding and cutting machine

A technology of water electrolysis and hydrogen, applied in the direction of gas flame welding equipment, electrolysis process, electrolysis components, etc., can solve problems such as tempering, impracticality, water spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

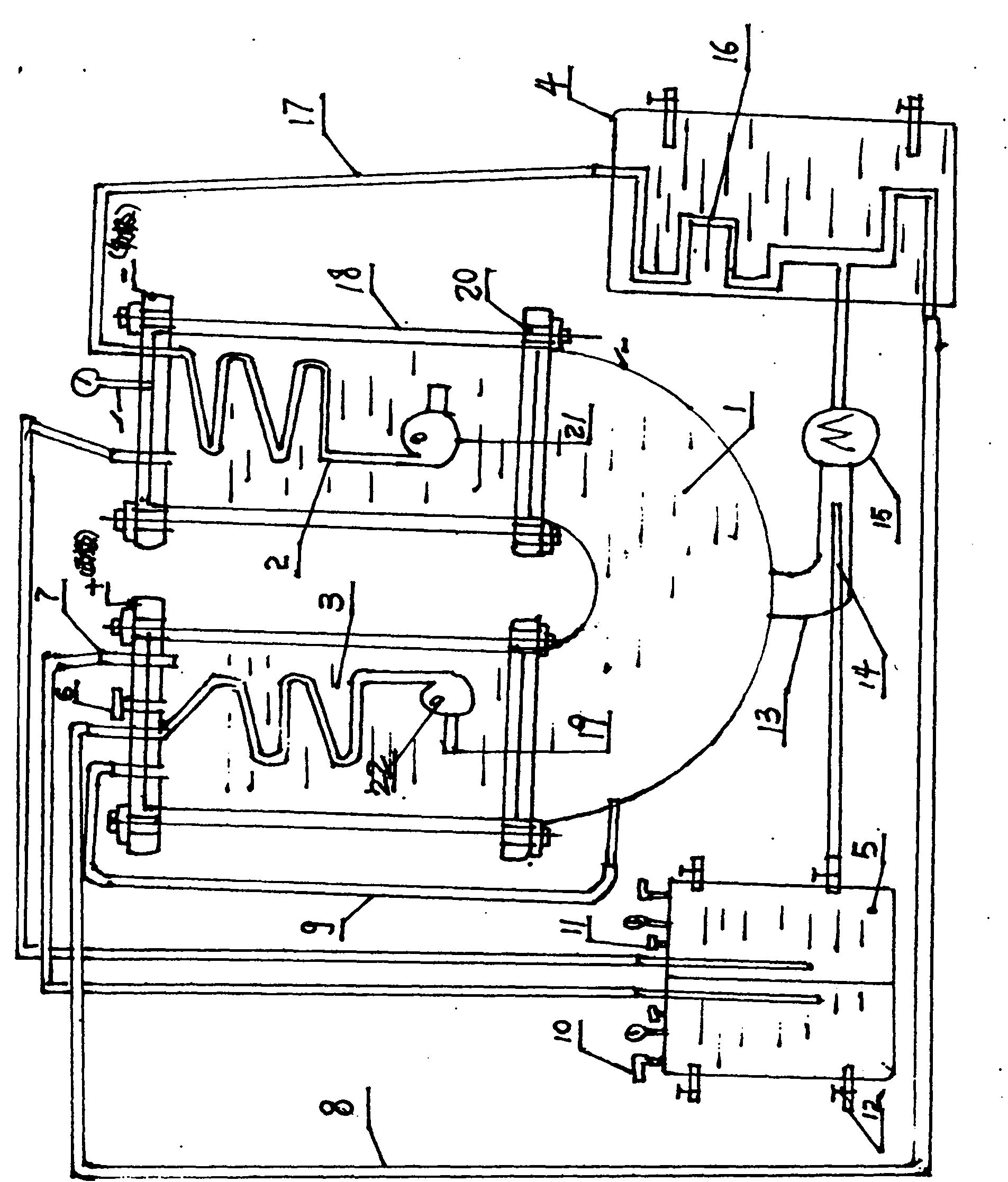

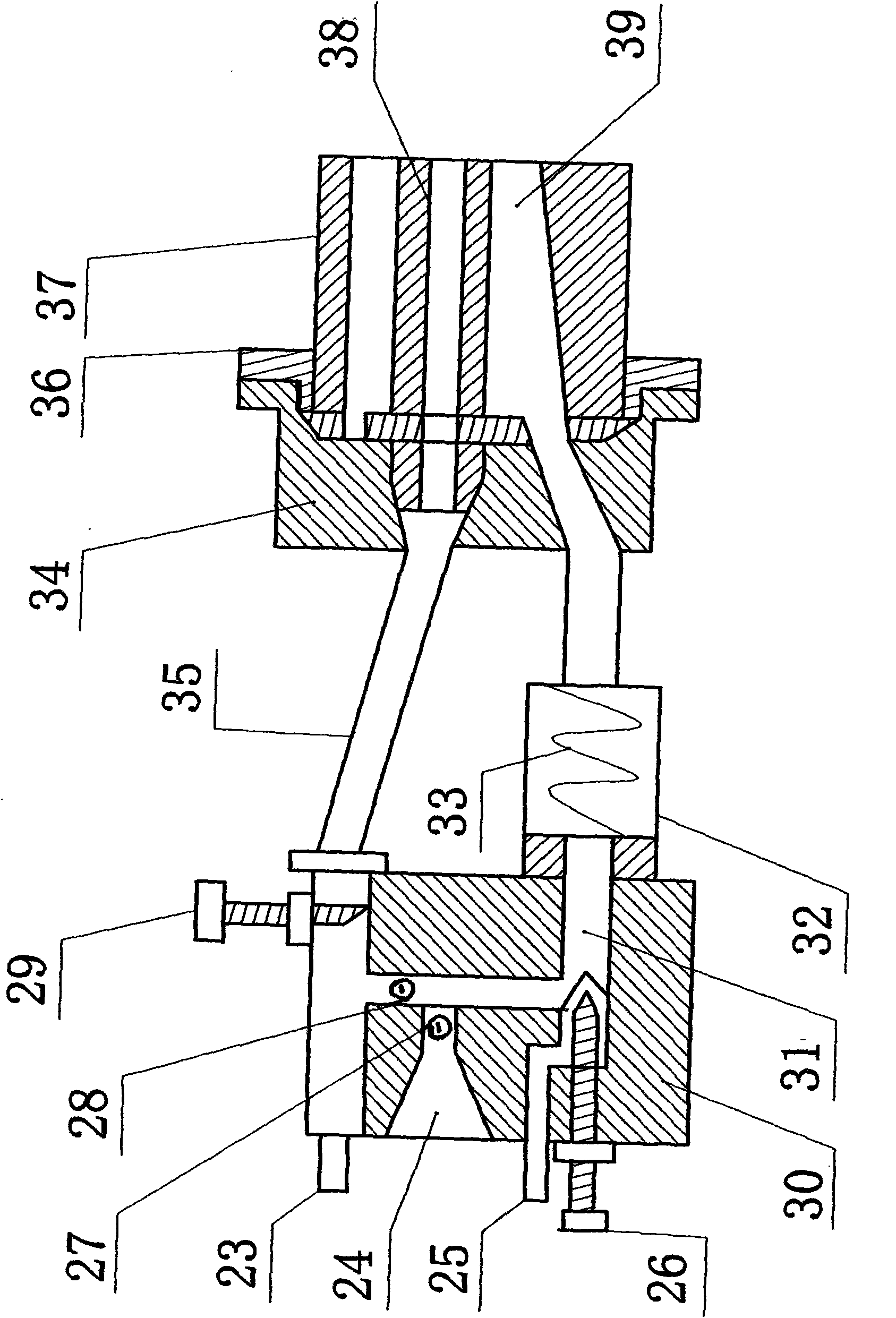

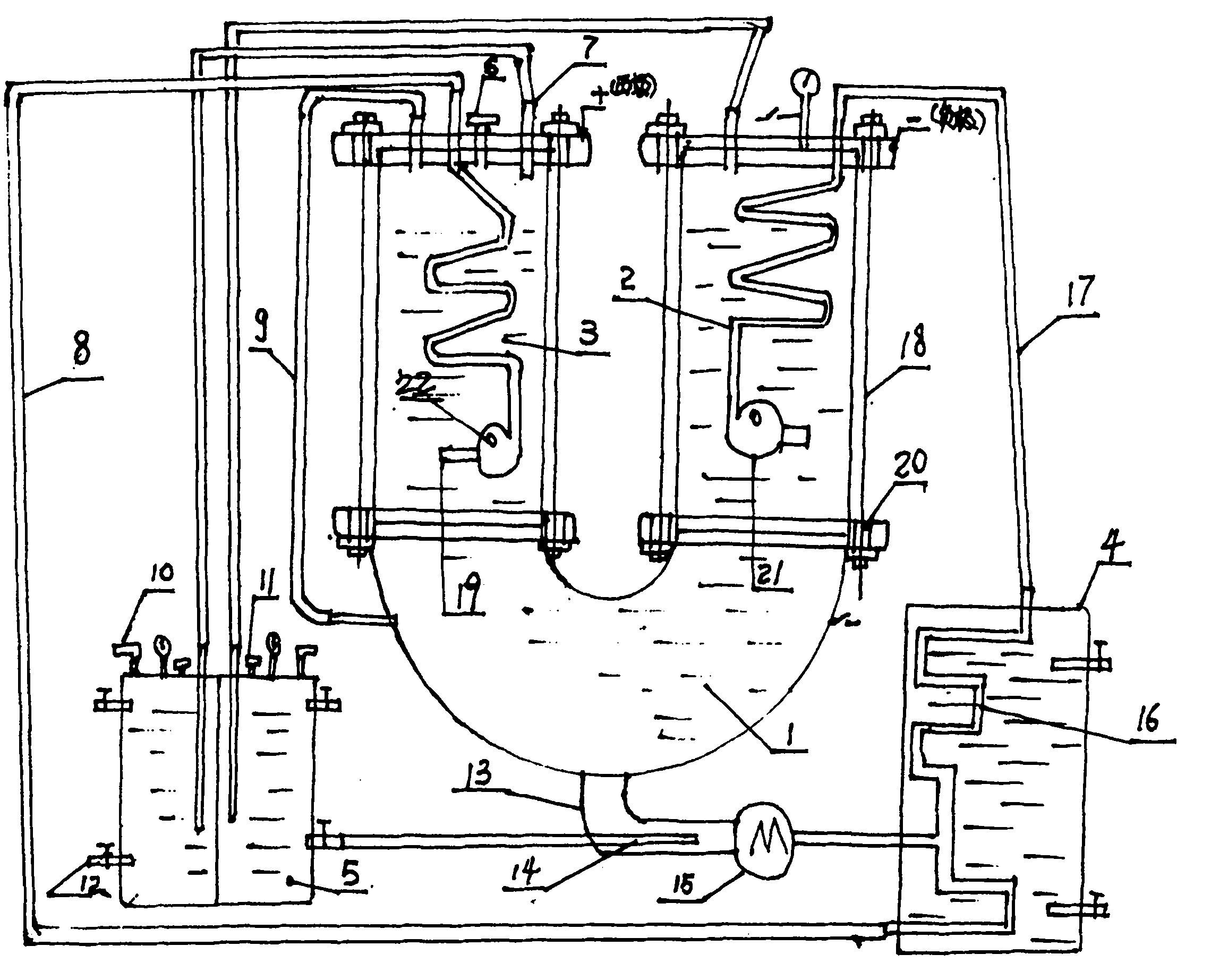

[0011] refer to figure 1 , figure 2 , 1-U-shaped electrolytic cell, 2-electrode copper tube, 3-plastic cylinder, 4-heat exchanger, 5-flame arrester, 6-explosion-proof vent, 7-stainless steel connecting pipe, 8-plastic hose, 9 -Water level indicator pipe, 10-Oxygen outlet connecting pipe, 11-Explosion-proof air outlet, 12-Valve, 13-Connecting pipe, 14-Metal suction pipe, 15-Water pump, 16-Heater pipe, 17-Plastic hose, 18 -screw rod, 19-nozzle, 20-insulating sleeve, 21-stainless steel hollow ball, 22-plastic marble, 23-oxygen connecting pipe, 24-air inlet, 25-hydrogen connecting pipe, 26-thimble valve, 27-Valves, 28-Valves, 29-Valves, 30-Air duct copper block, 31-Hydrogen suction and injection channel, 32-Hydrogen and oxygen mixing tube, 33-Copper spiral piece, 34-Welding and cutting head, 35-Copper tube , 36-fastening nut, 37-welding and cutting tip, 38-high pressure oxygen outlet, 39-hydrogen-oxygen mixture outlet. An innovative point of the present invention is that there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com