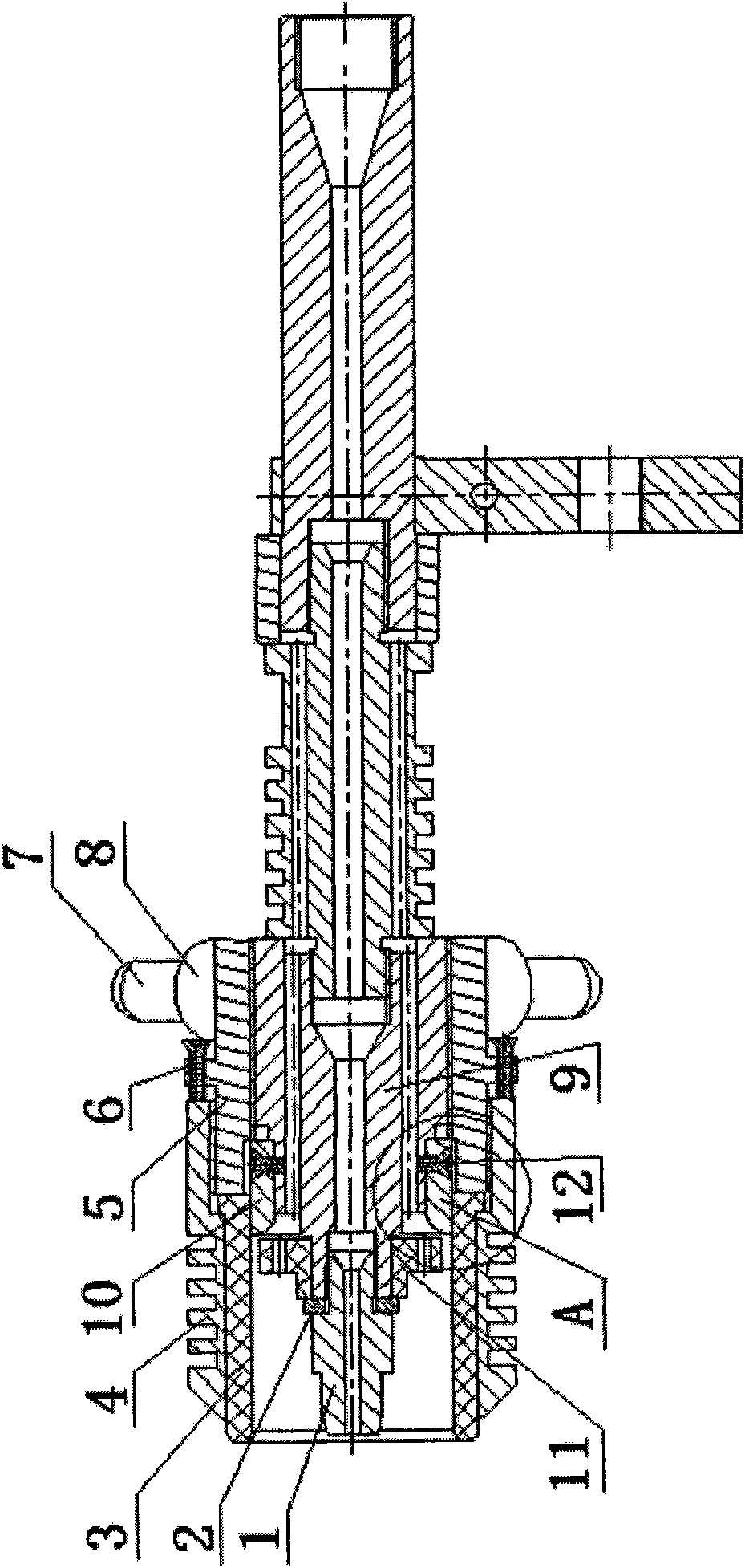

Novel self-rotating large-current MAG (Magnetic) welding composite nozzle welding gun for removing slag and slag removing method thereof

A high-current, slag-removing technology, applied in arc welding equipment, electrode accessories, welding equipment, etc., can solve the problems of complex structure and high cost, and achieve obvious effects of slag removal, extended life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

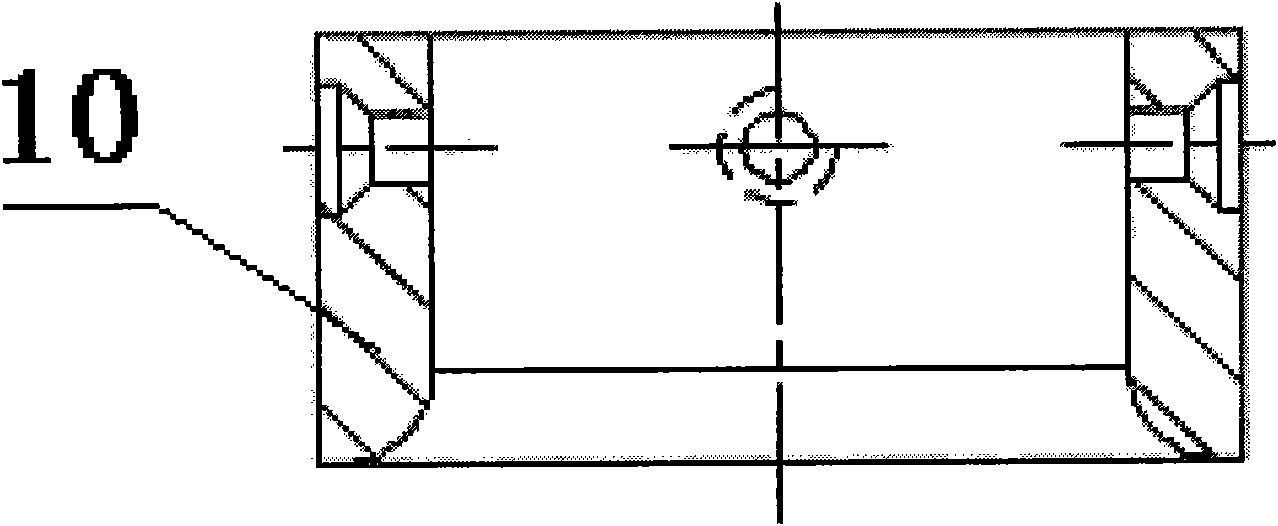

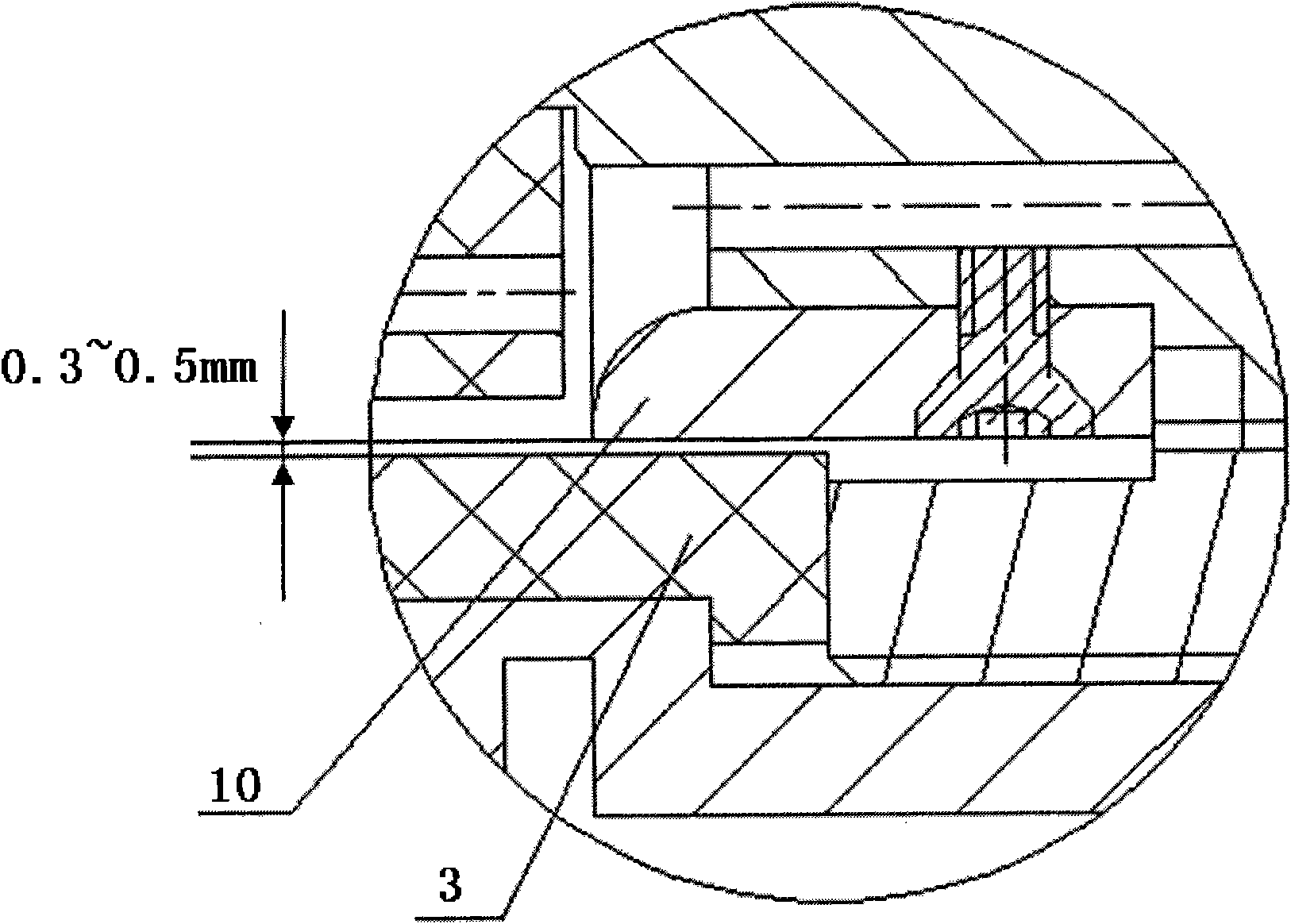

Method used

Image

Examples

Embodiment Construction

[0044] The welding torch of the present invention is used in the pre-welding process of the spiral pipe production of CNPC Baoshishun Steel Pipe Co., Ltd. The pre-welding of the spiral welded pipe is carried out inside the forming machine for continuous and uninterrupted production. The longer the welding time, the shorter the time for each stop to clean up the spatter, and the higher the production efficiency, especially for small diameter pipes of 508-610mm. Cleaning the torch inside is more difficult.

[0045] Using MAG welding, the main process parameters are as follows:

[0046] Current 650-1000A, voltage 21-23V, welding wire CHW-60C, specification φ3.2, welding speed 3.5-5m / min.

[0047] The continuous welding time of this welding torch is 80-120 minutes, and the slag removal time is about 30 seconds; compared with the original all-copper water-cooled welding torch, the production time of one continuous welding is about 40 minutes, and the slag removal time is 15-20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com