Production equipment for aluminium triethyl

A production equipment and technology of triethylaluminum, which is applied in the fields of compounds containing elements of Group 3/13 of the periodic table, chemical instruments and methods, organic chemistry, etc. Smooth and other problems, to achieve the effect of high industrial efficiency, process optimization, convenient aluminum powder feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

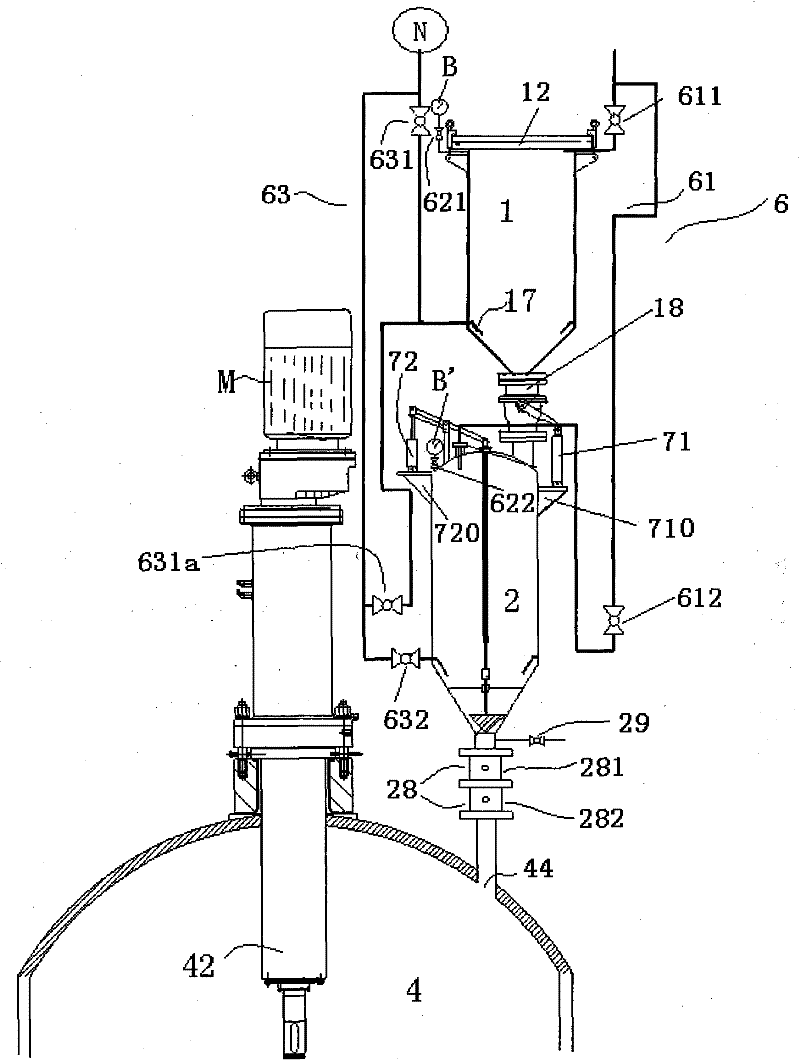

[0071] see Figure 1-6 Shown, a kind of production equipment of triethylaluminum, comprises aluminum powder feeding control system and reactor 4;

[0072] The aluminum powder feeding control system is composed of an aluminum powder feeding device and a control unit 6. The aluminum powder feeding device includes a feeding device 1 and a feeding device 2. The aluminum powder feeding control system passes through the reactor 4. Feed inlet 44 delivers aluminum powder to the reactor;

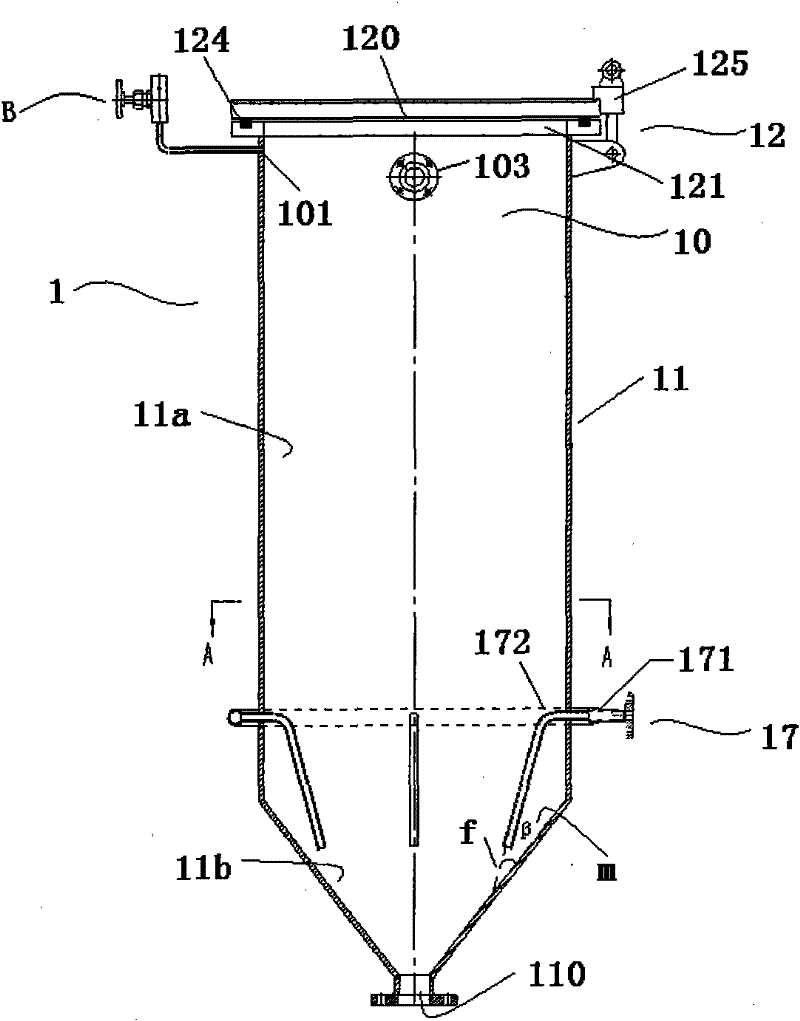

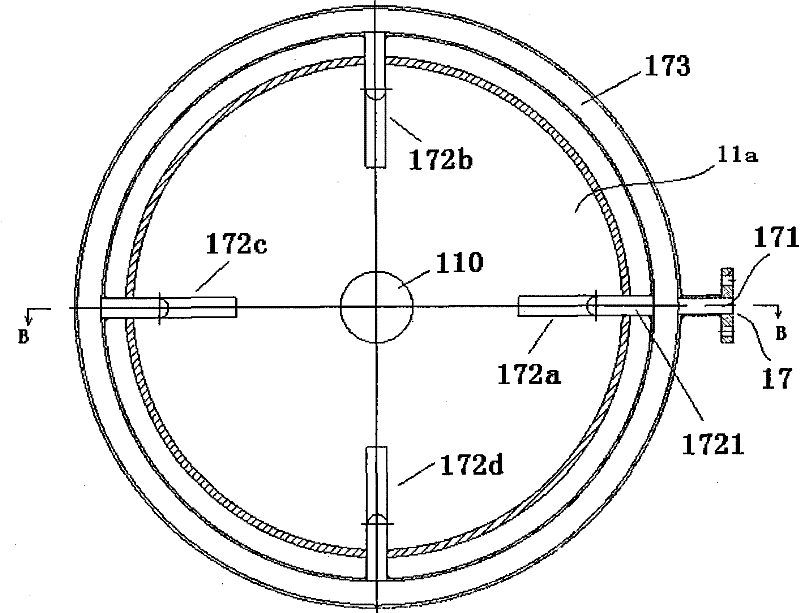

[0073] The feeding device 1 is used for nitrogen replacement of aluminum powder, see figure 2 , Figure 2a , Figure 2b As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com