Lightweight building block for roadbed and retaining wall

A kind of retaining wall, lightweight technology, applied in the direction of roads, roads, infrastructure engineering, etc., can solve the problems of post-construction settlement of roadbed too large, high project cost, high roadbed filling, achieve strength self-support, reduce project cost, The effect of reducing the rear earth pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

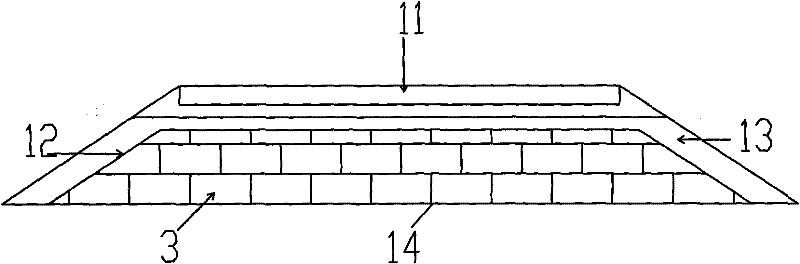

[0025] Such as figure 2 As shown, the block of the present invention is used for roadbed backfilling.

[0026] Craftsmanship

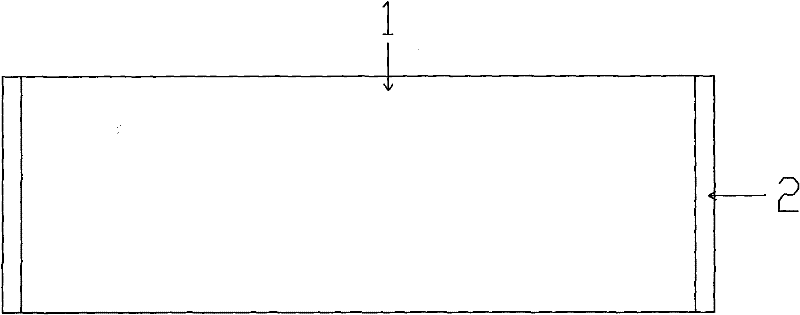

[0027] Mix and stir fly ash, additives (lime and cement) and water in a mass ratio of 2:1 (0.8:0.2):1 to make slurry, and pour it into waste tires 2 . It only needs to be primed into the rubber tire beforehand. Fly ash and discarded rubber tires are used to turn waste into treasure and solve the problem of environmental pollution.

[0028] construction technology

[0029] Compared with the traditional roadbed construction method, this new material made of fly ash and discarded tires only needs to arrange and connect the new block materials in advance according to the design requirements, and the other construction procedures are the same. Simple and fast construction. The construction process is as follows:

[0030] Leveling the site - measuring and positioning - completing the construction of a unit - moving to the next position - laying geotex...

Embodiment 2

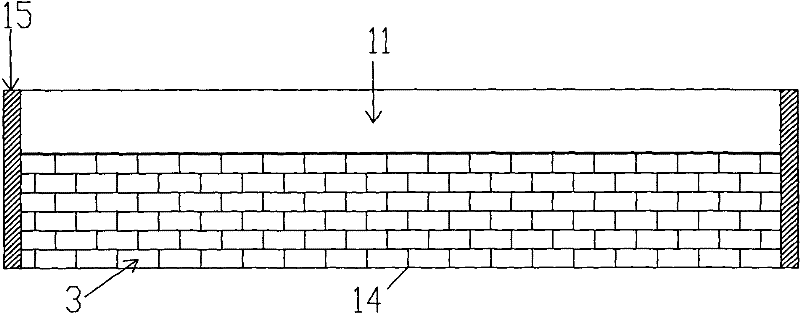

[0032] Such as image 3 As shown, the block of the present invention is used for backfilling the retaining wall.

[0033] Craftsmanship

[0034] Mix and stir fly ash, additives (lime and cement) and water in a mass ratio of 2:1 (0.8:0.2):1 to make slurry, and pour it into waste tires 2 . Fly ash and discarded rubber tires are used to turn waste into treasure and solve the problem of environmental pollution.

[0035] construction technology

[0036] Compared with the traditional retaining wall construction method, this new material made of fly ash and discarded tires only needs to arrange and connect the new block materials in advance according to the design requirements, and the other construction procedures are the same. , The construction is simple and the construction speed is fast. The construction process is as follows:

[0037] Leveling the site - measuring and positioning - completing the construction of a unit - moving to the next location - backfilling - completi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com