Electricity-saving economical civil-engineering multiple-layer fixed goods shelf all-in-one novel refrigeration house

An economical and integrated technology, applied in refrigeration plants, industrial buildings, building components, etc., can solve problems such as heavy weight of top-layer reinforced concrete frame brickwork, insufficient insulation material, and damage to reinforced concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

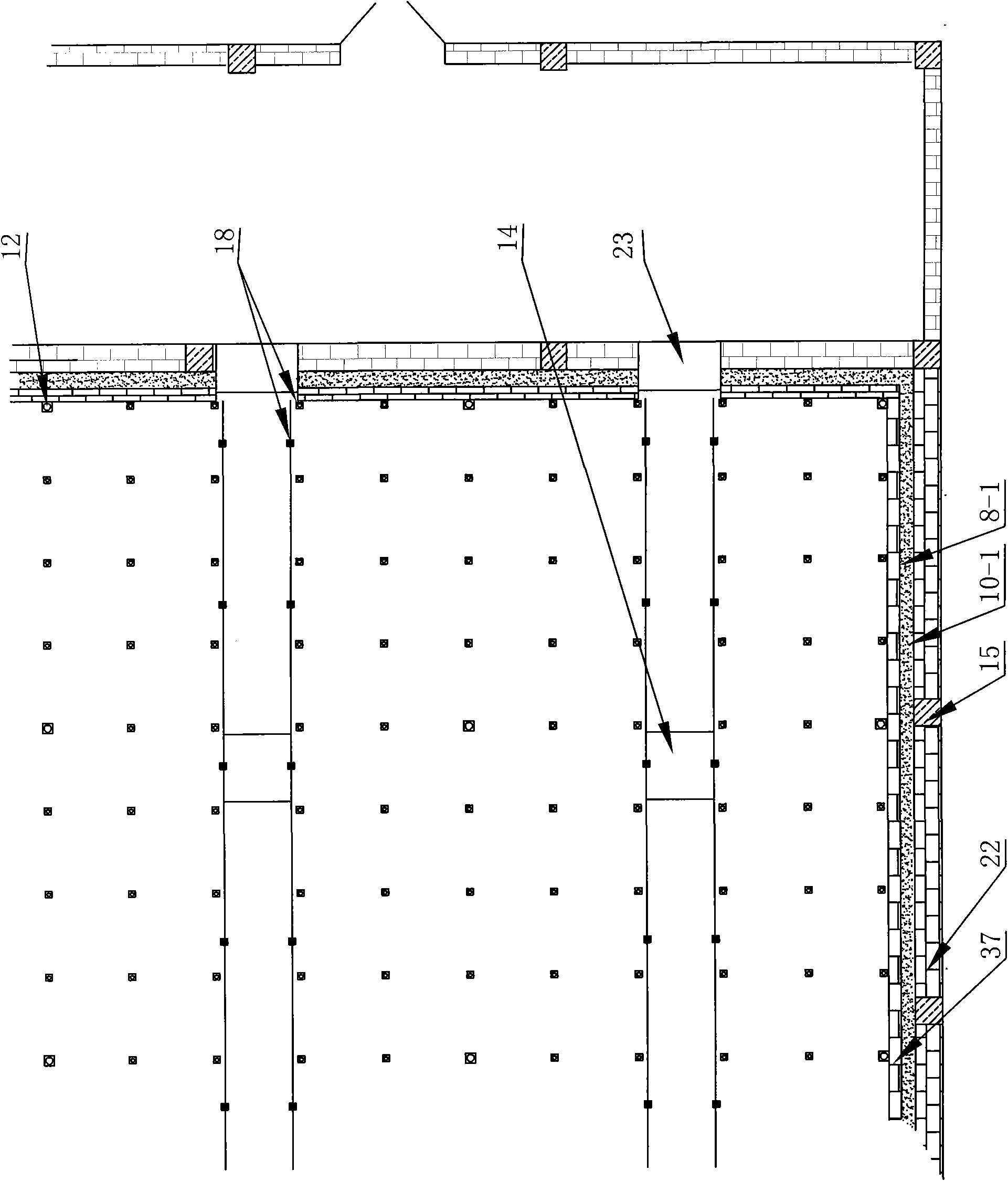

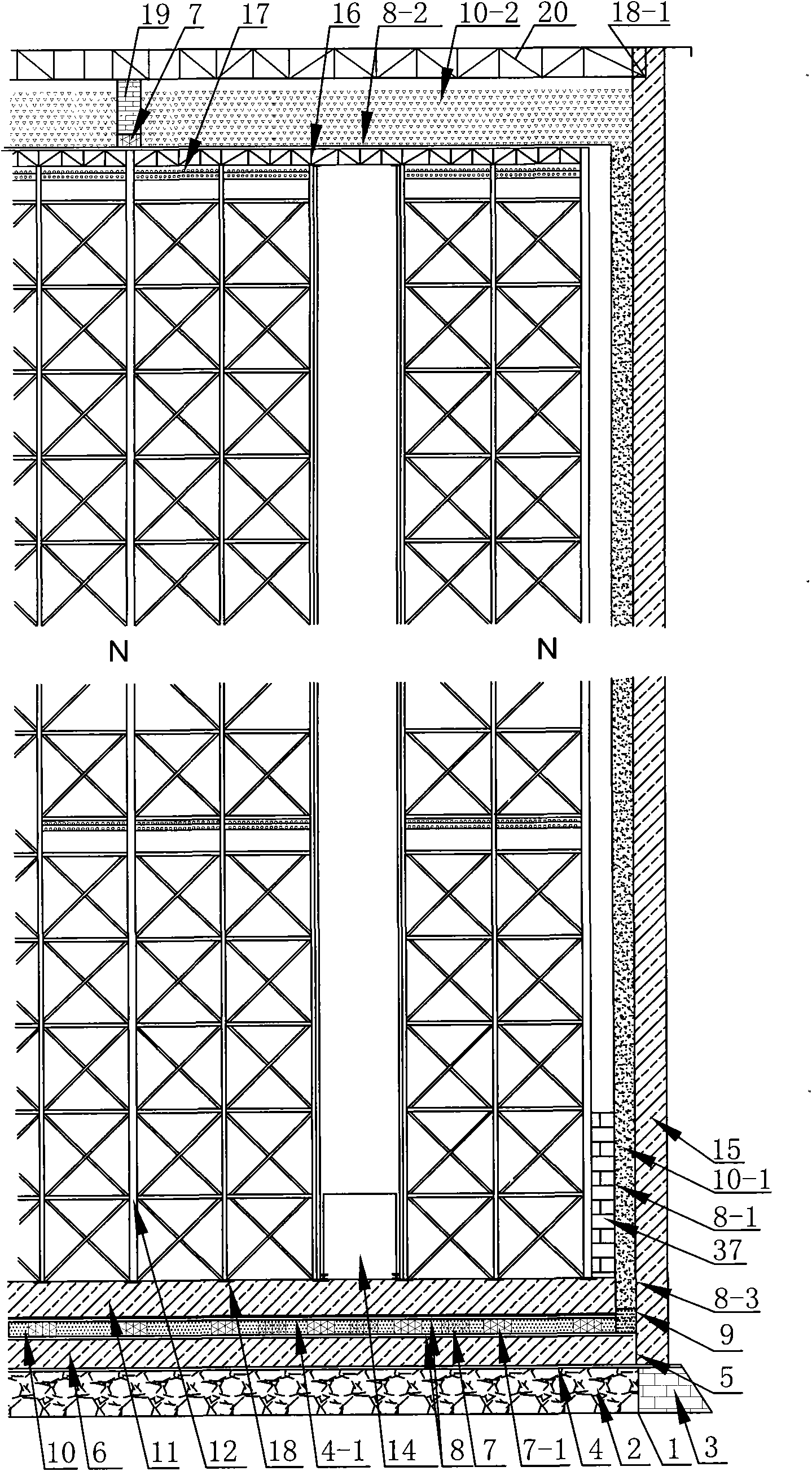

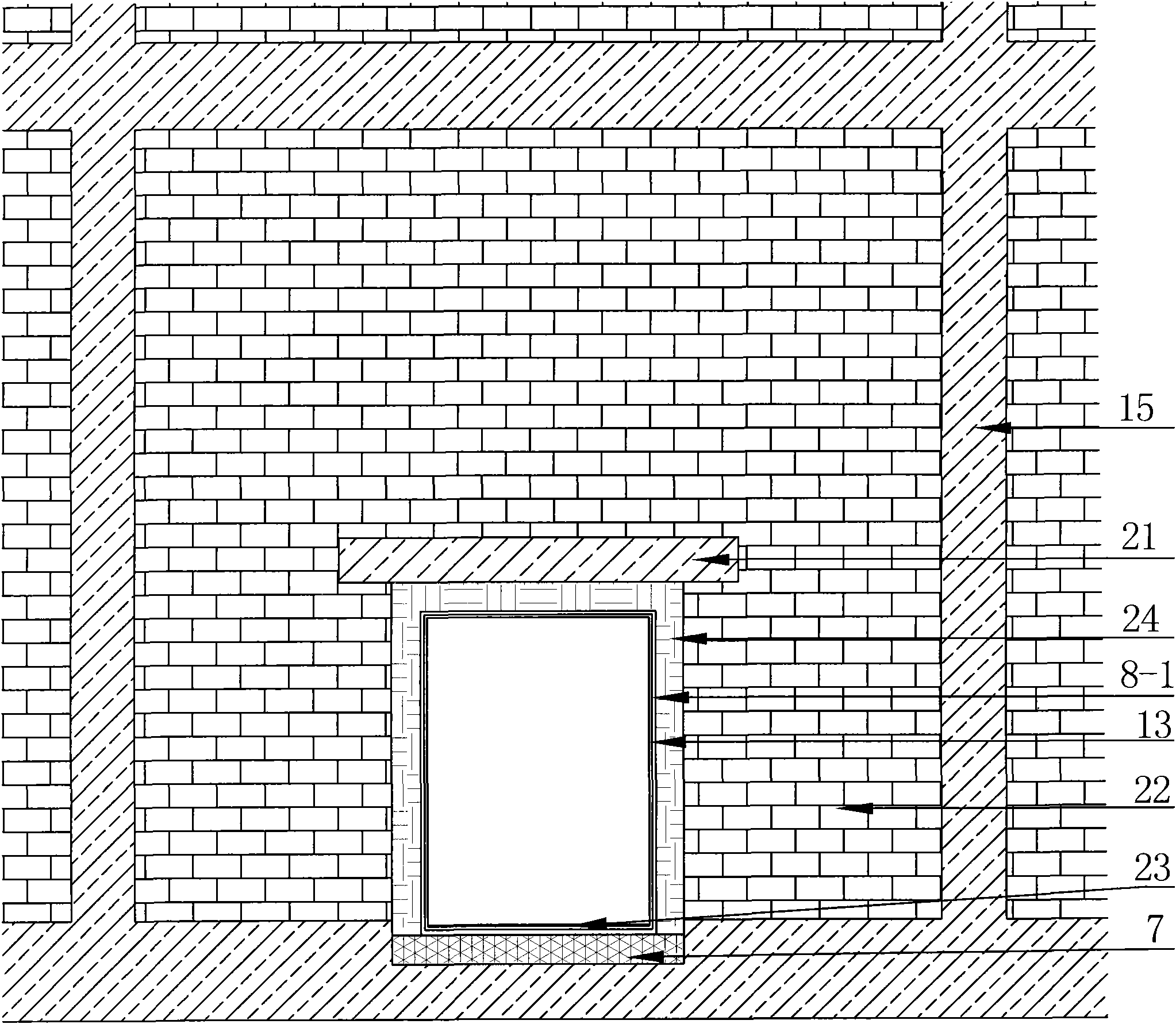

[0046] Such as figure 2 As shown, all excavation and rowing are carried out on the part above the original hard layer 1 required by the energy-saving and economical civil construction multi-layer fixed shelf integrated new cold storage; after that, stone masonry with saturated mortar for wall foundation 3; and stone masonry with saturated mortar for wall foundation 3 The inner cobblestone sand shaking layer is constructed, and the cobblestone sand shaking layer 2 is constructed by water shaking and vibration rolling; after that, the cement mortar cushion layer 4 on the cobblestone shaking sand layer is constructed, and the drainage pipe 5 around the thick trough-shaped reinforced concrete foundation 6 is installed at the same time. Insert the pebbles into the sand-shaking layer 2 and reserve the thickness of the thick trough-shaped reinforced concrete foundation above the cement mortar cushion layer; then carry out the construction of the thick trough-shaped reinforced concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com