High-efficiency hydraulic twisting machine capable of staggering orifice

A high-efficiency technology of a pipe twisting machine, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problem of axial floating of the unscrewing drill pipe, the lack of automatic centering function of the pipe twisting machine, and the drilling pipe. and equipment life impact, to achieve the effect of large torque, prolong life and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A high-efficiency hydraulic pipe wringer that can open the orifice of the present invention is mainly composed of the following parts:

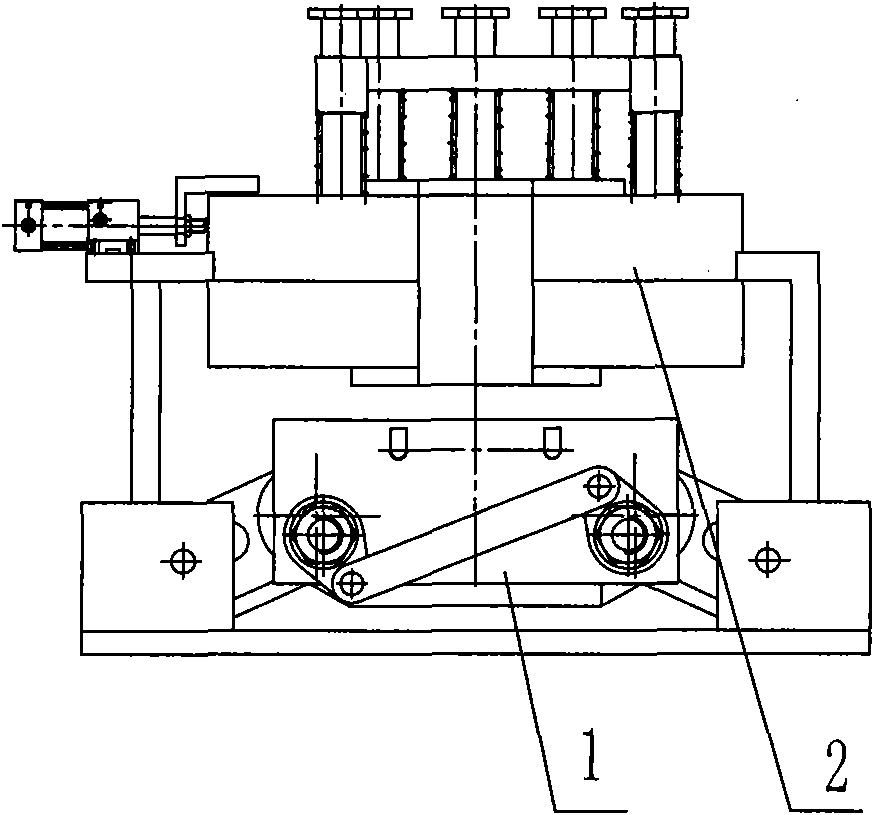

[0039] (1) Lower clamp: The lower clamp clamps the drill pipe at the lower section of the hole, supports the self-weight of the drill pipe in the drill pipe hole, overcomes the pre-tightening or punching torque, and prevents the upper drill pipe from rotating or slipping in the hole when it is unscrewed. .

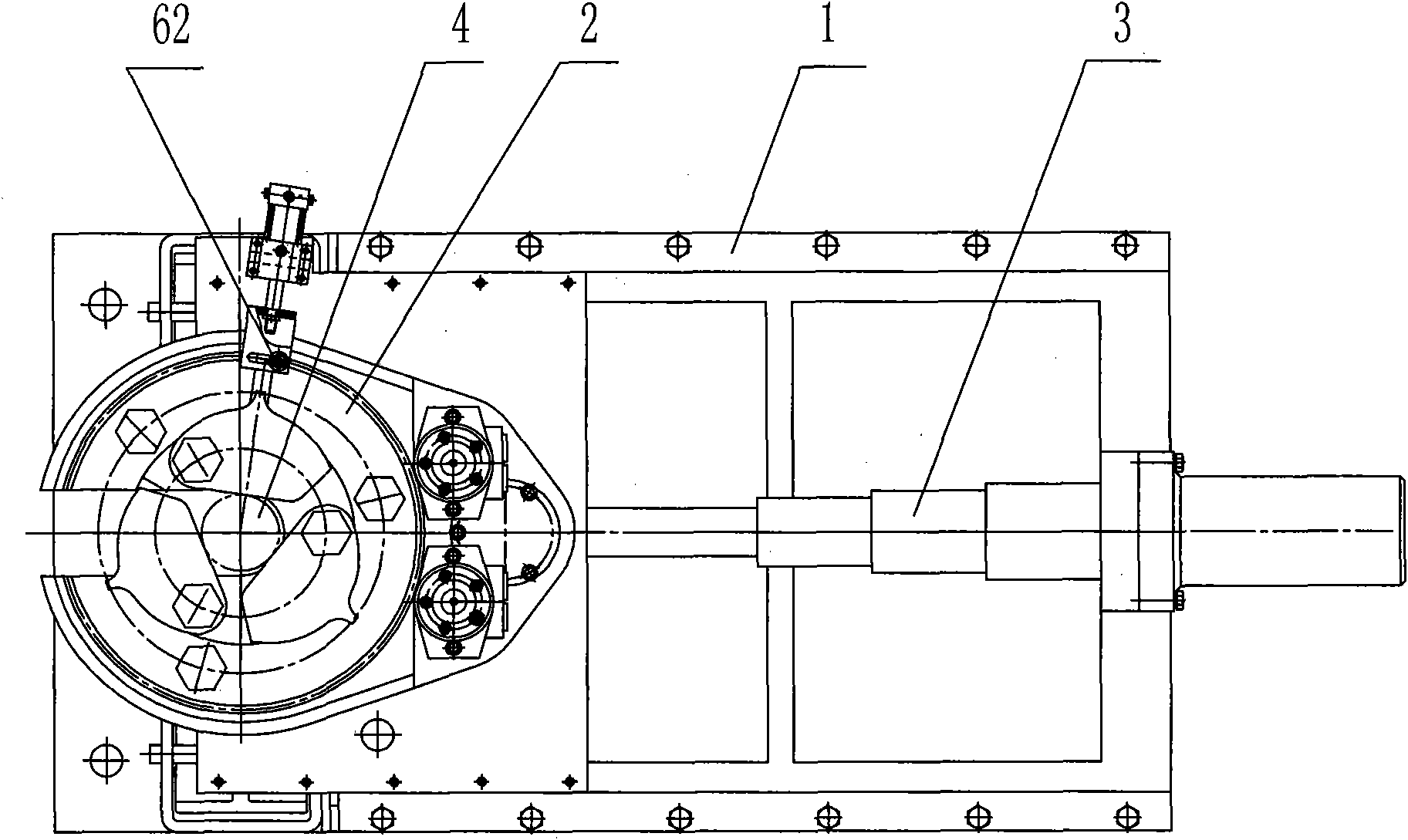

[0040] (2) Upper tong: The upper tong mainly completes the axial telescopic compensation in the process of clamping, screwing / unloading and unscrewing of the upper drill pipe.

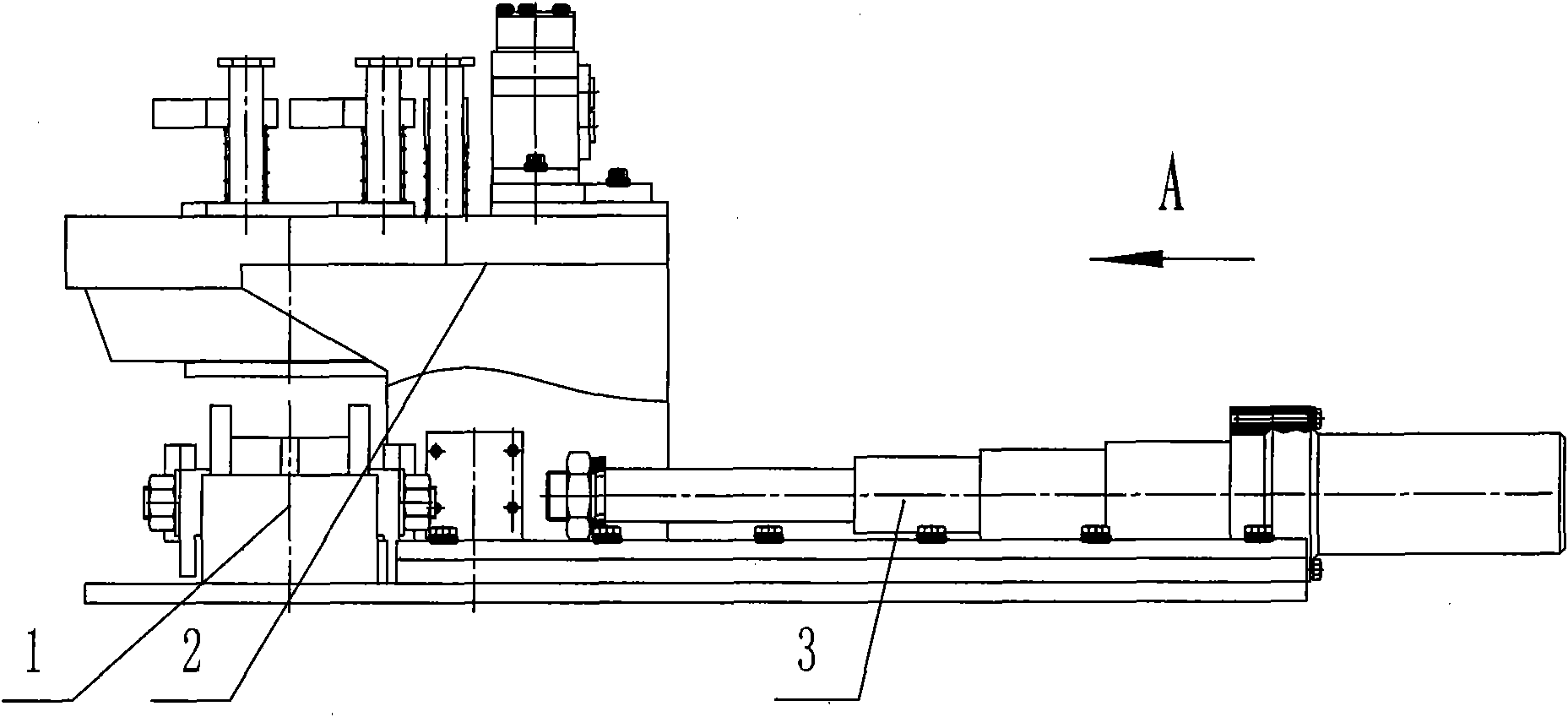

[0041] (3) Horizontally move hydraulic cylinder 3 (get out of the orifice): due to the limited space in the orifice, horizontally move the hydraulic cylinder to retreat to the edge of the hole when the pipe twister does not need to be used, so as to facilitate the operation of the orifice.

[0042] (4) Hydraulic system part: The pipe twisting machine adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com