LED automobile lamp

A technology of LED car lights and LED devices, which is applied in the field of car lights, can solve the problems of high stability requirements, increase the complexity of car light production, increase the difficulty of heat dissipation of LED car lights, etc., achieve stable performance, simple and compact equipment structure , Increase the effect of heat transfer expansion surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

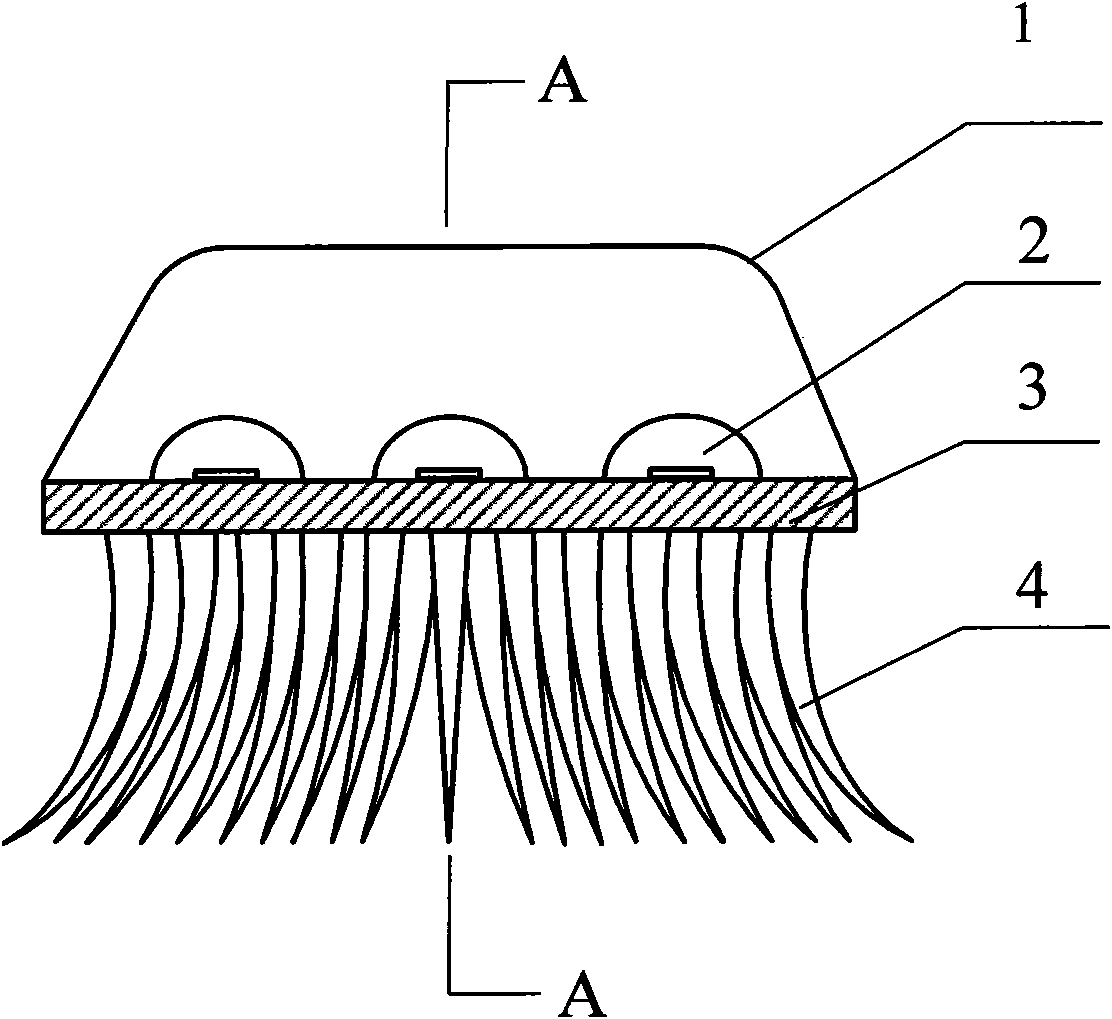

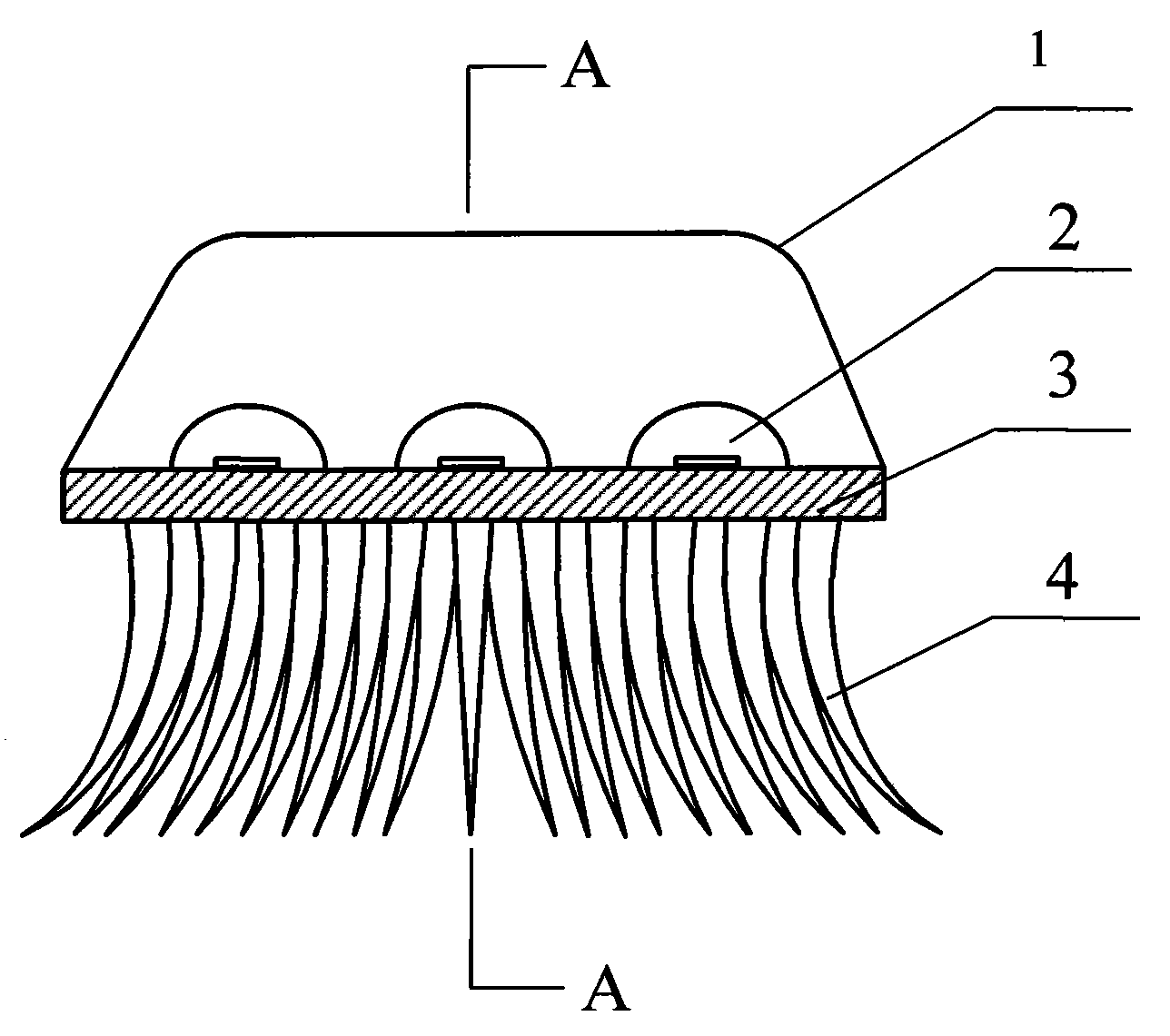

[0018] Below with reference to accompanying drawing, specific embodiment of the present invention is described in more detail:

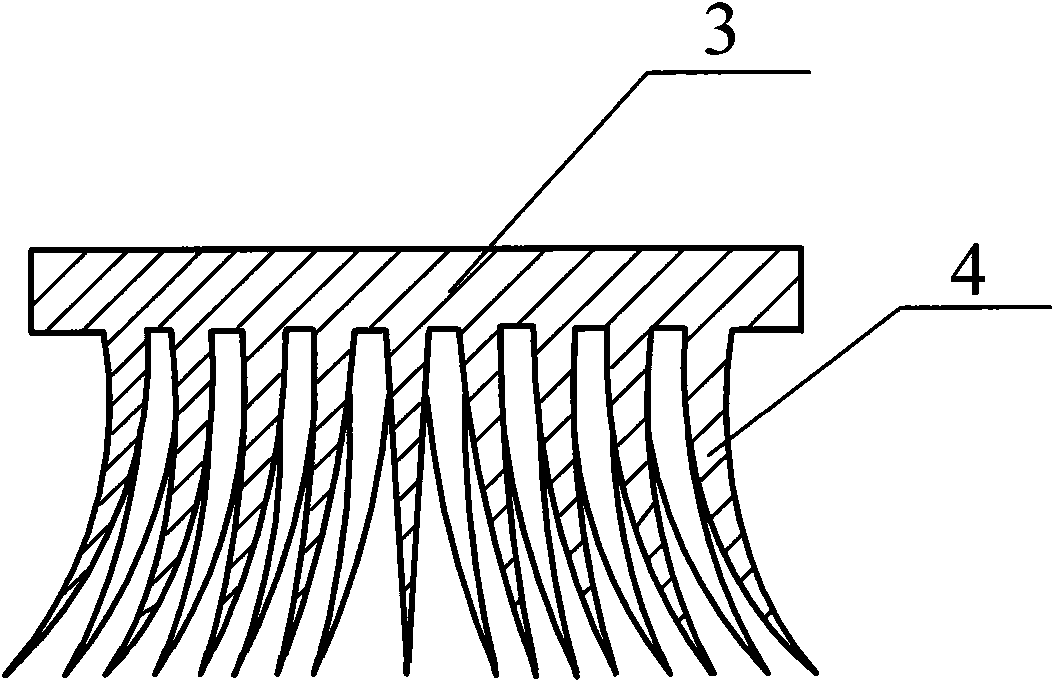

[0019] A pin-fin type LED automobile lamp, comprising a lamp housing 1, an LED device, a heat-conducting substrate 3 and pin-fins 4, the heat-conducting substrate 3 and the pin-fins 4 are integrally cut, there is no contact thermal resistance, and the heat transfer efficiency is high.

[0020] The pin fins 4 at the center point of the heat conduction substrate 3 are perpendicular to the heat conduction substrate 3, and the pin fins 4 not at the center point of the heat conduction substrate 3 are along the direction connecting the root and the center of the heat conduction substrate 3 and facing away from the center point of the heat conduction substrate 3 One side of the pin fin 4 is bent, and the angle between the tangent line of the pin fin 4 and the heat conduction substrate 3 gradually decreases with the increase of the distance between the root p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com