Integrated Hall-effect sensor

A Hall effect and sensor technology, applied in the field of integrated Hall effect sensors, can solve the problems of non-adjustable switching point, narrow use range, installation restrictions, etc., to achieve enhanced anti-vibration performance, wide application range, and increased stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

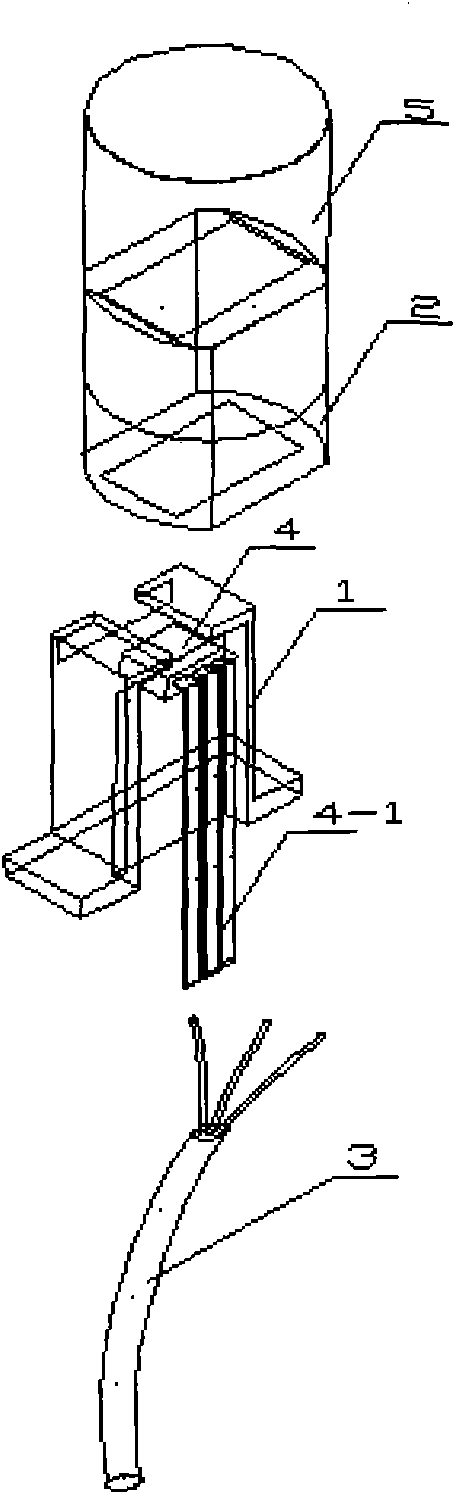

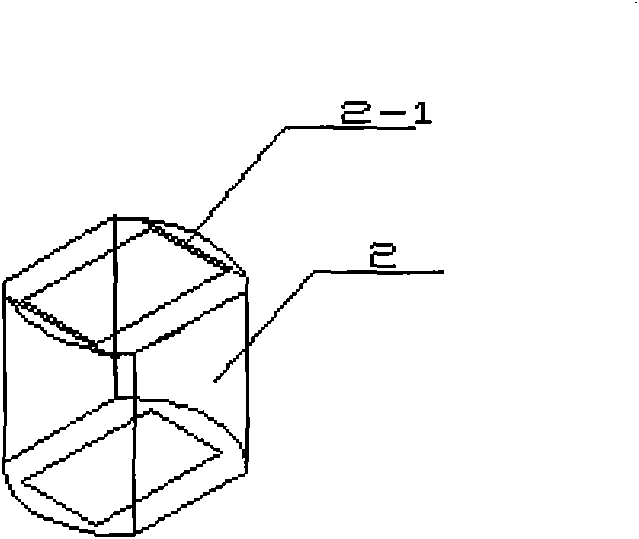

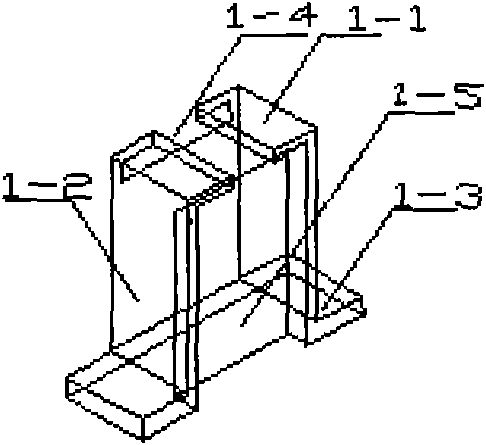

[0020] See figure 2 , 3 , The integrated integrated Hall-effect sensor of the present invention is composed of a direct plug-in bracket 1, a hollow shell 2, a lead set 3, and a Hall element 4. The bracket 1 includes a bracket top 1-1, a central axis support part 1- 2. Support base 1-3. The Hall element 4 is installed in the slot 1-4 on the top 1-1 of the bracket, the lead group 3 is soldered to the Hall element 4, and then the lead group 3 and the pin 4-1 of the Hall element 4 are installed together In the sliding groove 1-5 formed by the bottom bracket 1-2 and the bracket base 1-3. The bracket 1 is arranged in the inner square hole 2-1 of the hollow shell 2. Under normal circumstances, the top 1-1 plane of the bracket 1 and the top plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com