Beta particle three-pole ionization dust sensor

A dust sensor and particle technology, applied in the field of sensors, can solve the problems of inaccurate measurement of dust sensors, inability to monitor the workload of maintenance on-line for a long time, etc., and achieve the goal of overcoming the problem of automatic zero correction, reducing the maintenance workload, and overcoming the problem of signal drift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

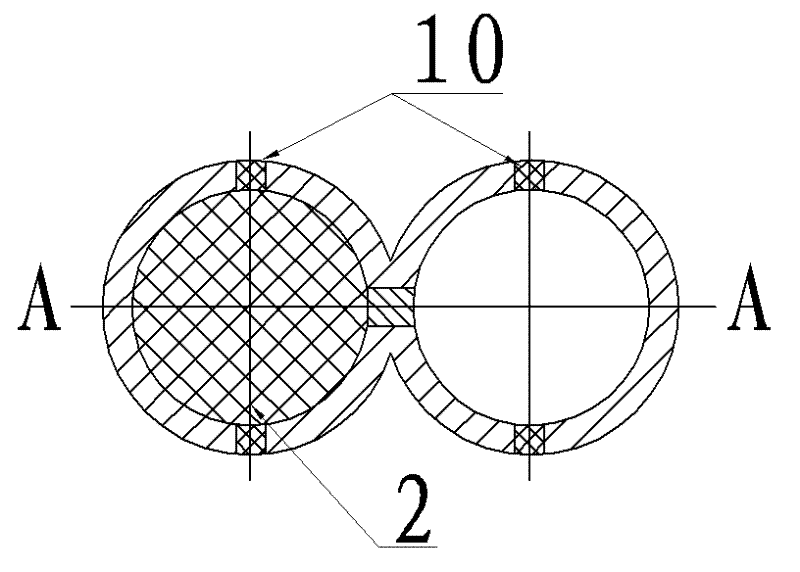

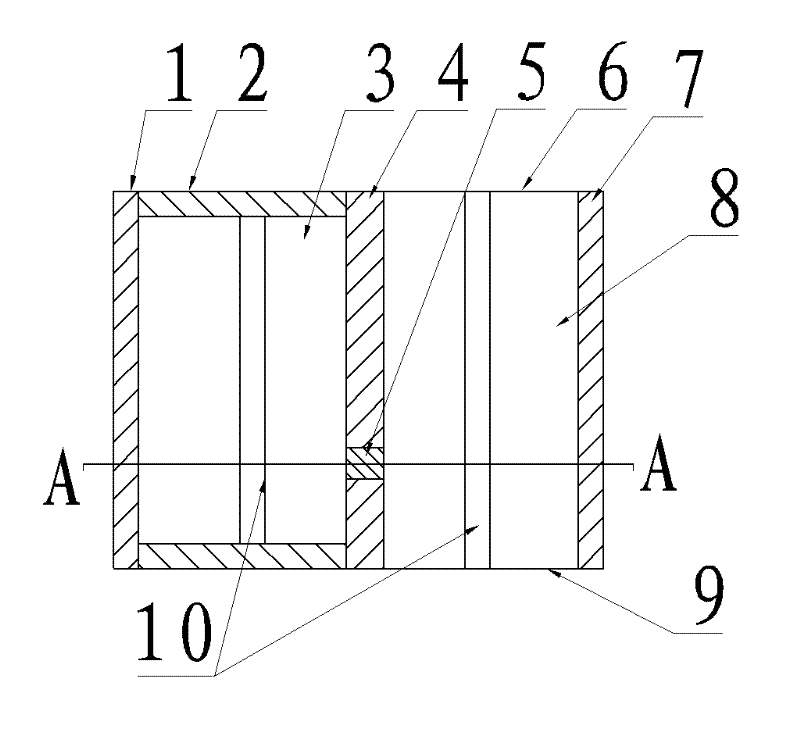

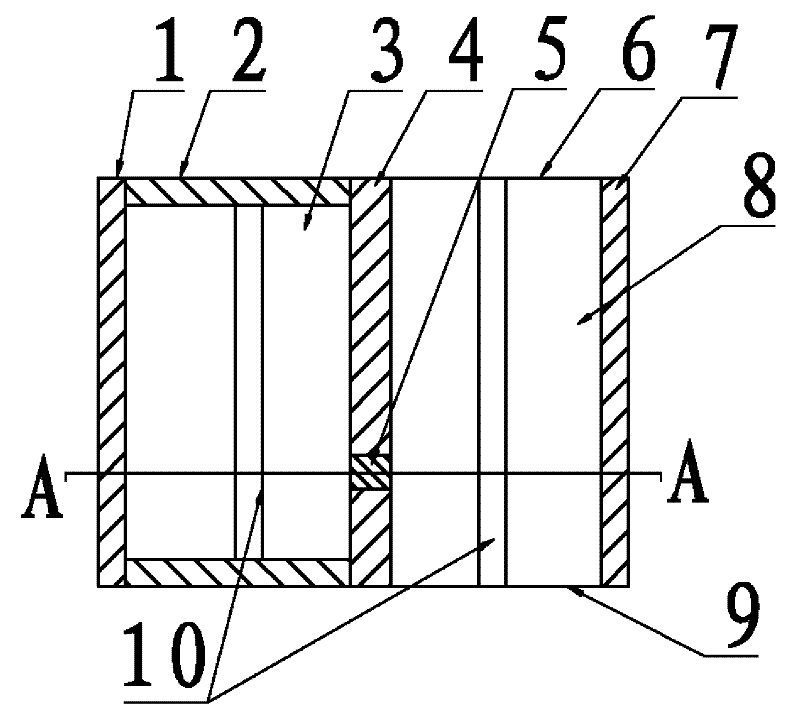

[0011] Such as Figure 1 ~ Figure 2 As shown, the structural diagram of the beta particle three-pole ionized dust sensor of the present invention includes a housing and a reference chamber 3 and a measurement chamber 8 arranged side by side in it, the reference chamber is formed by sealing the surrounding wall and the upper and lower end covers 2, and the measuring chamber is enclosed by the surrounding wall The two share a common negative pole 4, a reference positive pole 1 insulated from the common negative pole is provided on the surrounding wall of the reference chamber, a measuring positive pole 7 insulated from the common negative pole is provided on the surrounding wall of the measuring chamber, the measuring chamber 8 is connected up and down, and both ends An air inlet 6 and an air outlet 9 are respectively provided. The common negative electrode 4 is provided with a β source support 5, and the β source is coated on the two ends of the β source support respectively al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com