Mixing intelligent optimizing method for semiconductor production line production plan

A technology for production planning and intelligent optimization, applied in computing, instruments, data processing applications, etc., to achieve the effect of improving search speed and strong global search capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

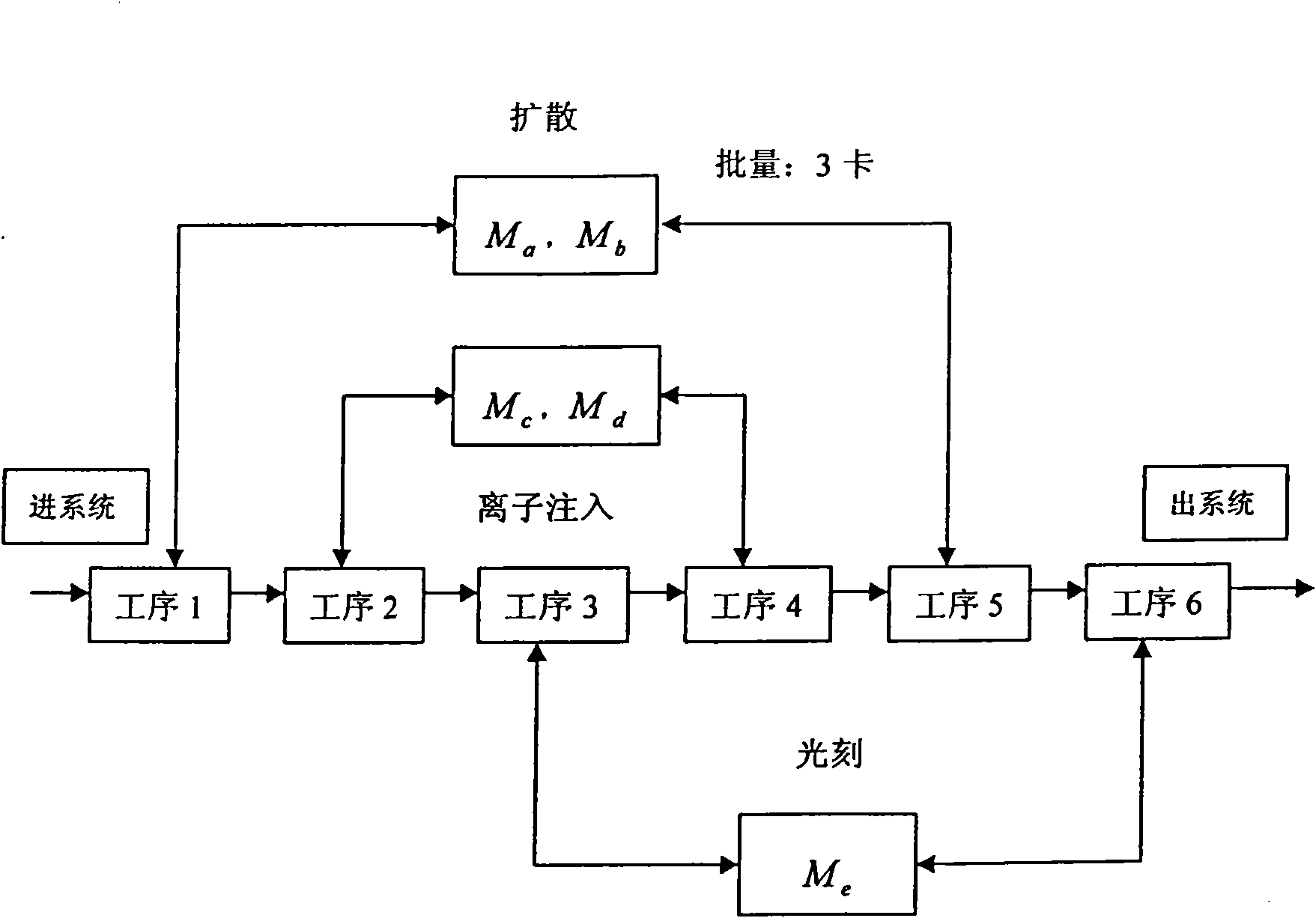

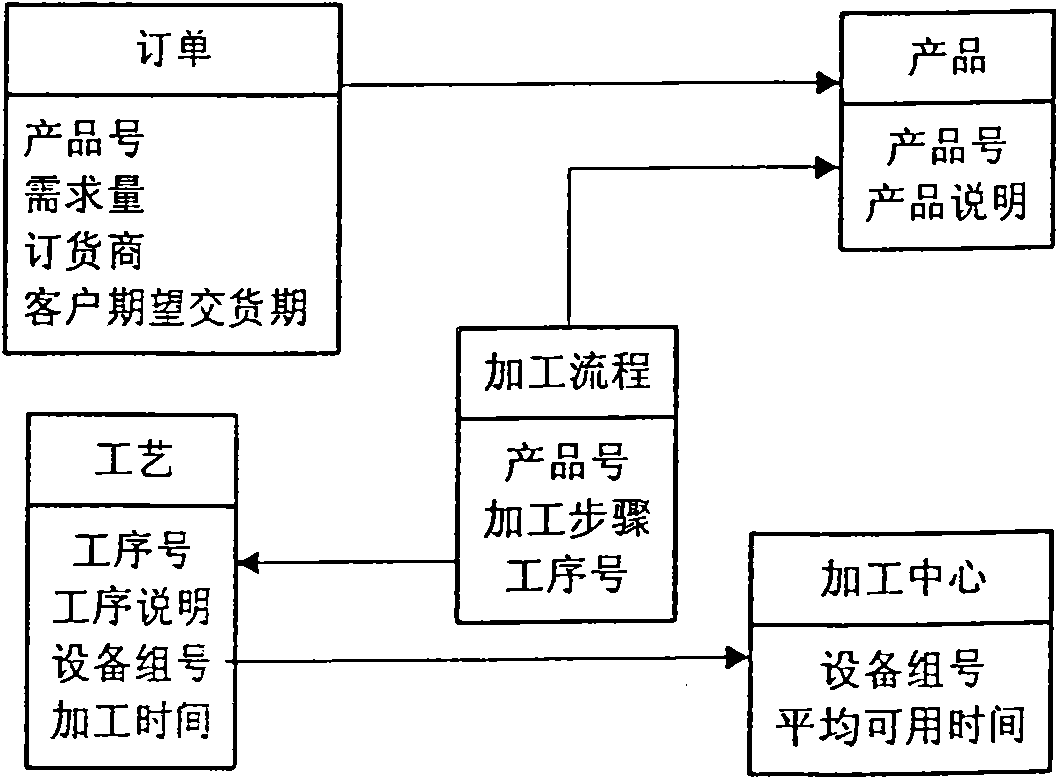

[0078] According to the idea of hierarchical optimization, it is divided into two parts. One is to establish a background database to store customer orders and related production information, and then realize the mathematical model of the material feeding plan under the fuzzy production capacity environment, and use the hybrid intelligent algorithm to solve the model to obtain the monthly material feeding plan. Then construct a heuristic strategy based on the urgency of product delivery and the length of the processing cycle to further refine the optimized monthly feeding plan into a daily feeding plan. The implementation details are introduced in detail below.

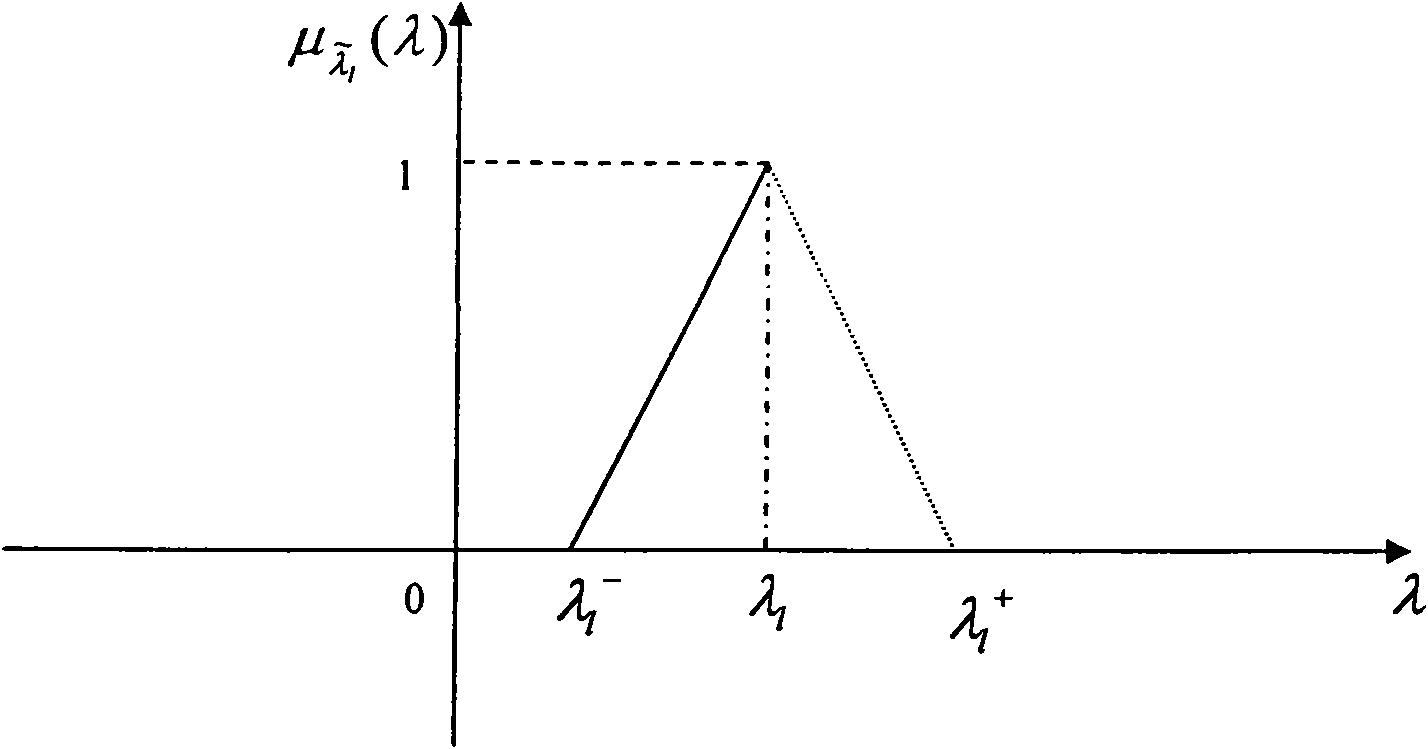

[0079] The realization of the mathematical model of material feeding plan under the environment of fuzzy production capacity. First, build a background database in Access to store customer order information and related production information (such as product information, processing center information, process inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com