Manufacturing method of polycrystalline silicon film material

A technology of polysilicon thin film and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of induced metal residue, uncontrollable induced metal diffusion, and long crystallization time, so as to improve grain size, Effect of reducing metal residue and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 6

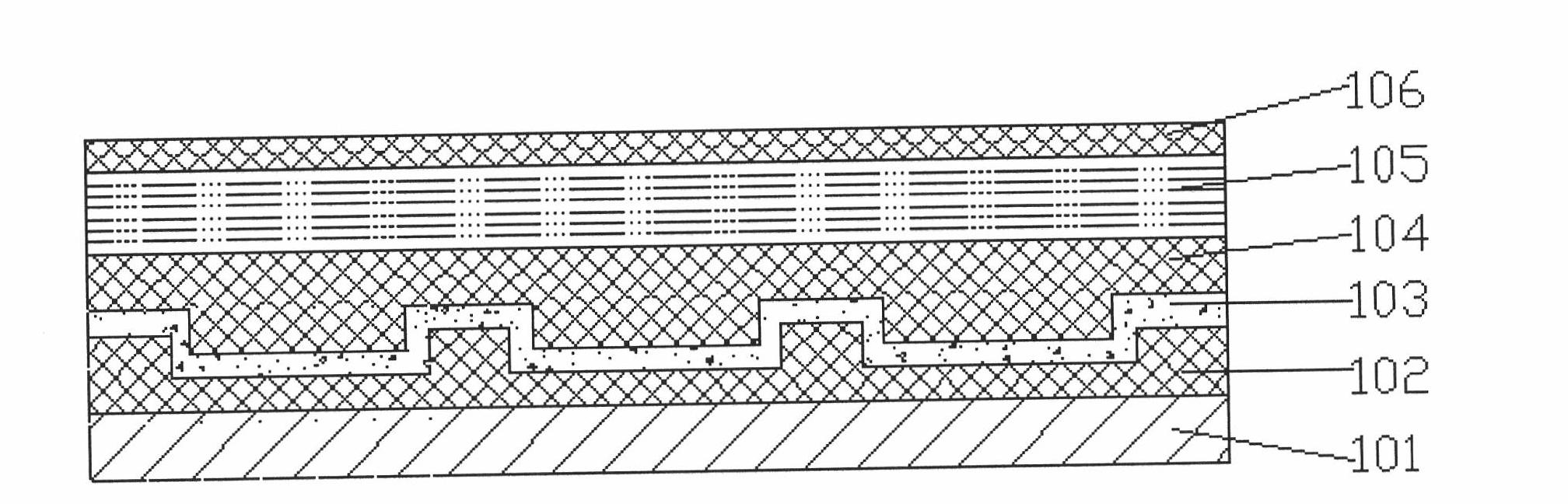

[0060] According to an example of the present invention (taking Example 6 as an example), the method for preparing polysilicon thin film material comprises the following steps:

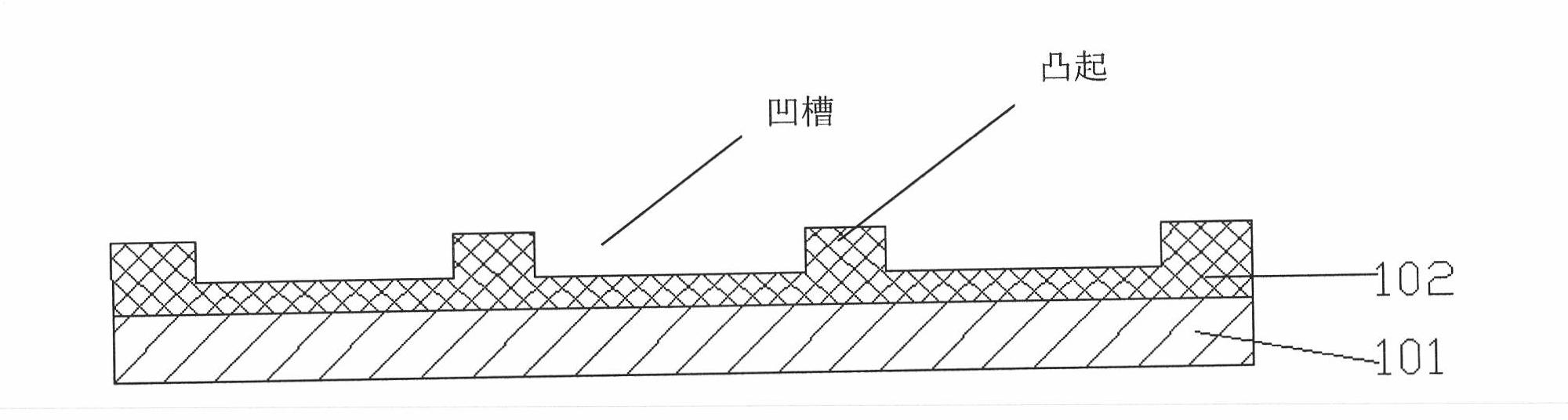

[0061] (1) select the glass substrate, adopt the PECVD method to deposit 1.0 micron low-temperature silicon oxide on the glass substrate as the barrier layer;

[0062] (2) Etching the barrier layer into a groove-shaped structure, wherein the protrusions have a rectangular cross-section, a width of 3 nanometers, a height of 3 nanometers (D=3.0nm), and a protrusion spacing of 60 microns;

[0063] (3) A layer of controllable nickel source is formed on the first isolation layer by sputtering as a metal induction layer, and the surface nickel concentration is 5×10 13 cm -2 ;

[0064] (4) Depositing a layer of barrier layer on the induction layer by PECVD method as the second barrier layer, the thickness of the second barrier layer corresponding to the protrusion of the first barrier layer is 1.5 nanomete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com