High pressure pulse generating system for obtaining random-wave-form forced response and working procedure thereof

An arbitrary waveform, high-voltage pulse technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problems affecting the detection efficiency, the instrument is not easy to move, the transformer is bulky, etc., to achieve flexible data processing, improve efficiency, and simple system structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

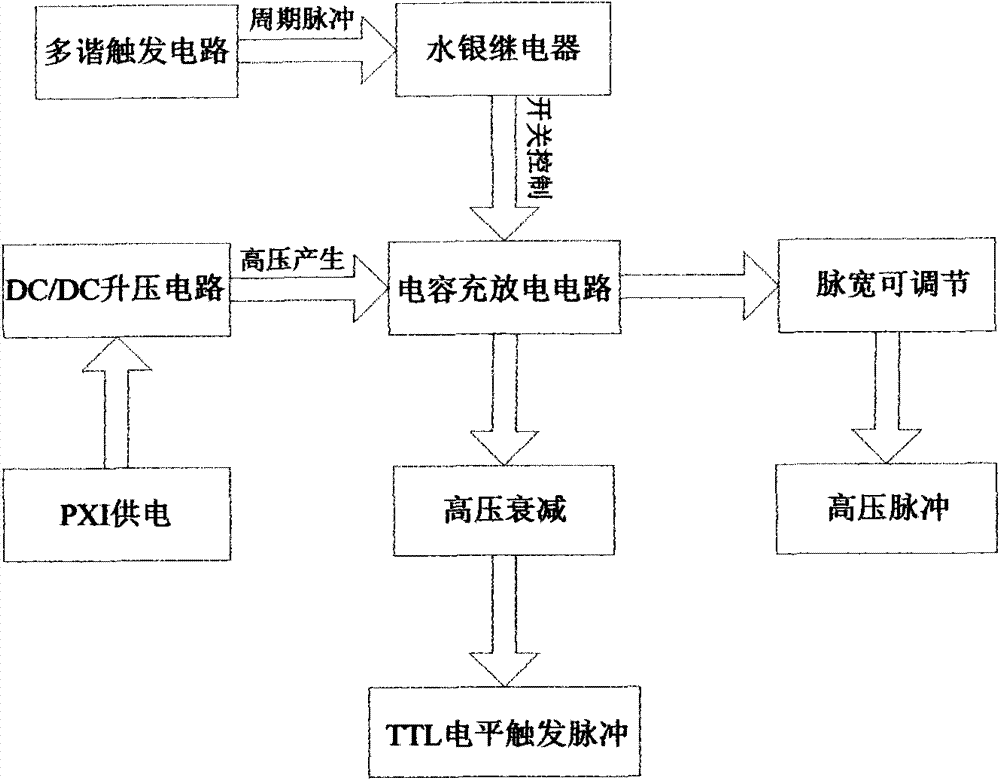

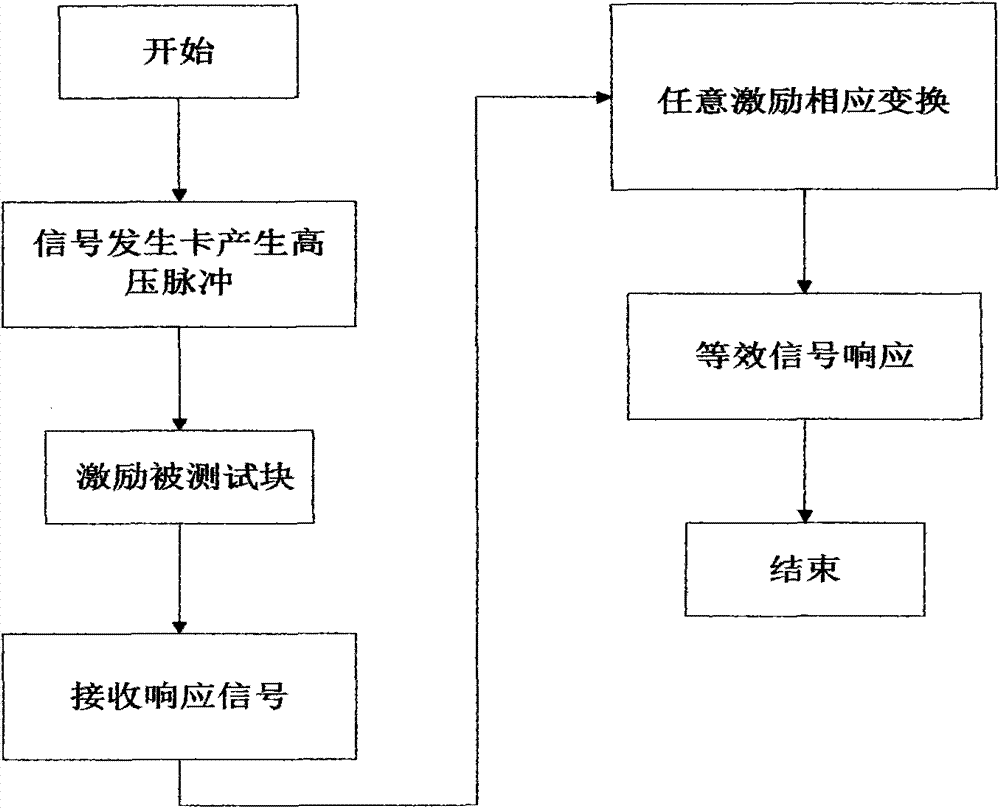

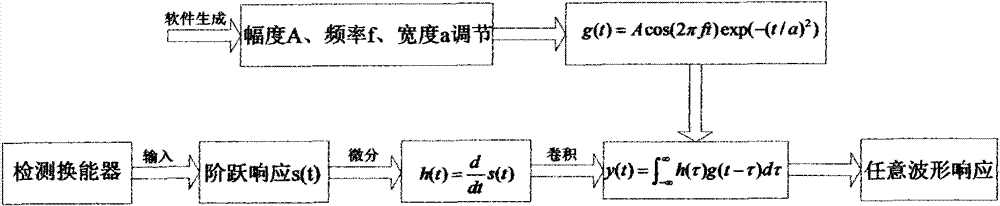

[0037] like figure 1 , figure 2 , image 3 Shown, the high-voltage pulse generation system that obtains arbitrary waveform excitation response of the present invention includes: 1) the high-voltage pulse generation circuit that is used to stimulate high-voltage pulse generation; 2) the PXI interface structure that is used to provide power; 3) is used to obtain direct current High-voltage DC / DC booster circuit; wherein all the above-mentioned circuits and structures are based on the PXI bus, and the high-voltage pulse generating circuit includes a capacitor charging and discharging circuit for generating high-voltage pulse signals with adjustable pulse width and synchronous trigger signals , used to control the discharge switch of the capacitor charging and discharging circuit and the multivibrator trigger circuit used to control the charging and discharging cycle. In this embodiment, the discharge switch used is a reasonably selected mercury relay with a sufficiently large ...

Embodiment 2

[0053] The system and method of embodiment 1 are compared with the effect of the prior art, such as Figure 4 As shown, the solid line represents the actual modulated wave response curve, that is, the excitation response of the pulse generated by the function generator and power amplifier to the structure under test. The dashed line represents the equivalent modulated wave response curve, ie, the response of the pulse generated by the system and method of the present invention to the excitation of the structure under test. Among them, the abscissa represents the number of sampling points, and the ordinate represents the relative amplitude of the curve. It can be seen from the figure that the actual modulated wave response curve basically coincides with the response curve generated by the system and method. That is, the system and method can completely replace other complex structures such as the existing function generator and power amplifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com