Method for processing blast furnace liquid slag and recycling energy and application thereof

An energy recovery and liquid slag technology, which is applied in recycling technology, seawater treatment, heating water/sewage treatment, etc., can solve the problems of high water consumption in blast furnace slag treatment system, and the inability to recycle the heat of blast furnace liquid slag for recycling rate, etc. The effect of achieving significant utilization value and improving cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

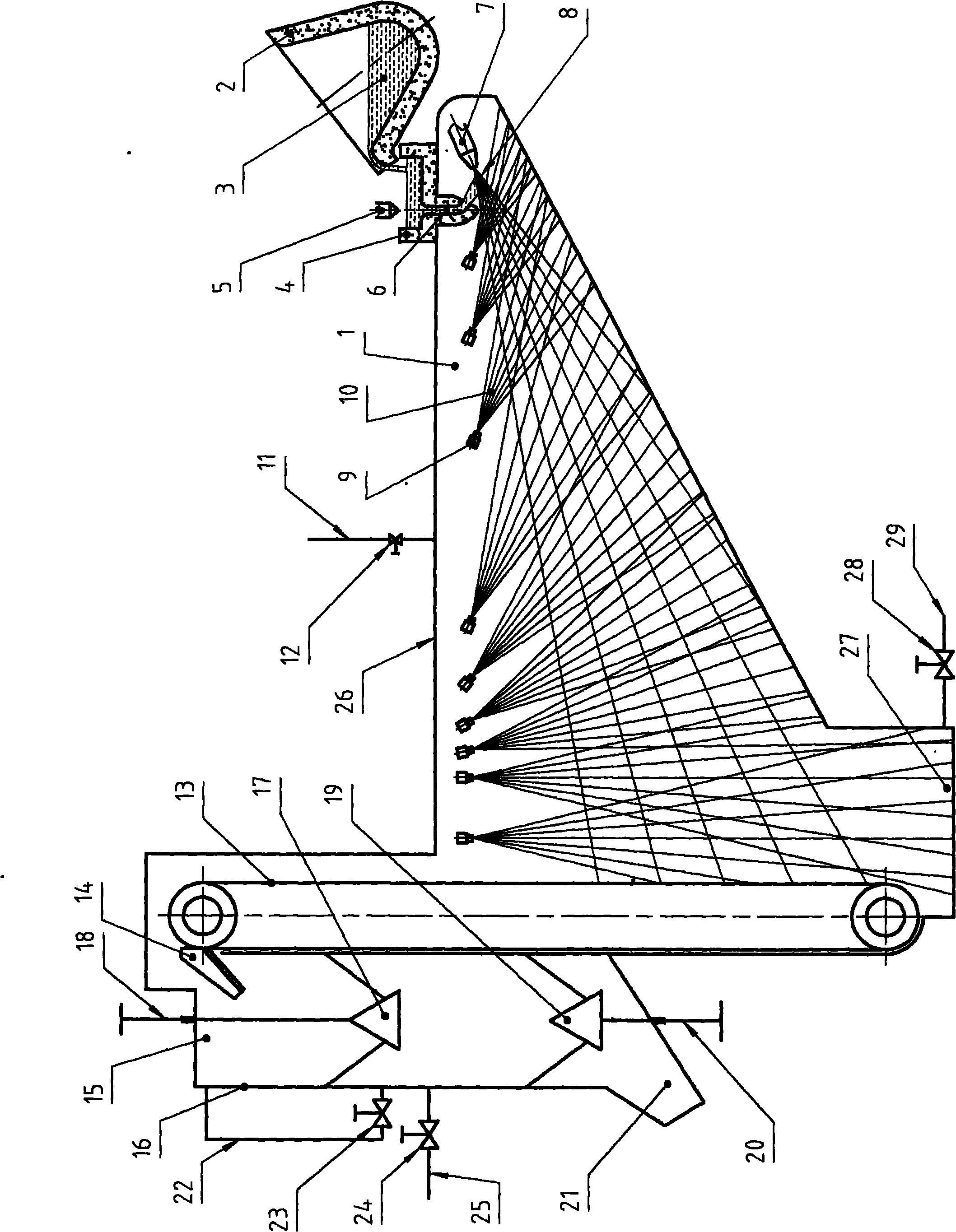

[0059] Example 1, such as figure 1 shown.

[0060] exist figure 1 Among them, 1 is the closed space, 2 is the slag tank, 3 is the slag liquid in the slag tank, 4 is the middle slag tank, 5 is the slag liquid control stopper of the middle slag tank 4, and 6 is the channel for the slag liquid to enter the closed space 1 , 7 is the nozzle of fluid water, 8 is the flow of fluid water ejected by the nozzle 7 of fluid water, 9 is the nozzle arranged in the closed space 1, 10 is the cooling water flow ejected from nozzle 9, and 11 is steam recovery Pipe, 12 is an on-off valve, 13 is a solid material hoist, 14 is a discharge chute of the hoist 13, 15 is a double material bell type discharge bin, 16 is a shell of the discharge bin 15, and 17 is a discharge bin 15 is the feeding bell, 18 is the control guide rod of the feeding bell, 19 is the unloading bell of the discharge bin 15, 20 is the control guide rod of the unloading bell 19, 21 is the discharge chute of the unloading bin 1...

Embodiment 2

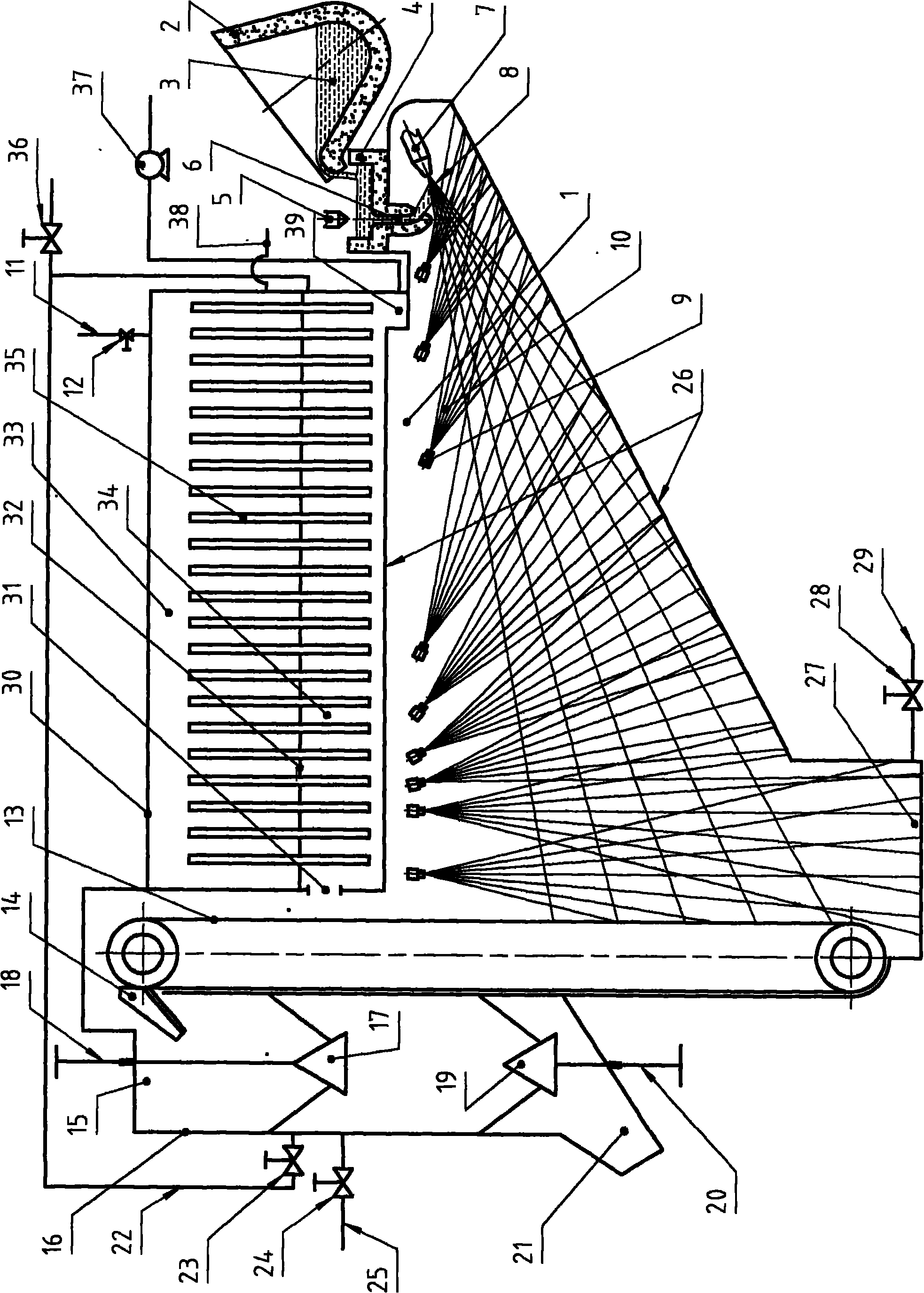

[0079] Example 2, such as figure 2 shown.

[0080] This embodiment only adopts an intermediate heat exchanger on the basis of embodiment 1 to isolate the steam containing dust and water mist.

[0081] exist figure 2 Among them, 30 is an intermediate heat exchanger, 31 is the entrance of the steam from the closed space 1 entering the intermediate heat exchanger 30, 32 is an intermediate partition that separates the intermediate heat exchanger 30 into an evaporation chamber 33 and a condensation chamber 34, and 35 is A heat pipe for heat exchange, 36 is a release valve, 37 is a hot water pump, 38 is a clean water inlet pipe, and 39 is a condensed water sump. Please refer to the relevant description of Embodiment 1 for the rest.

[0082] In this embodiment, the steam from the closed space 1 enters the condensation chamber 34 of the intermediate heat exchanger 30 through the inlet 31, and uses the heat pipe 35 to perform heat exchange, and the condensed water generated during...

Embodiment 3

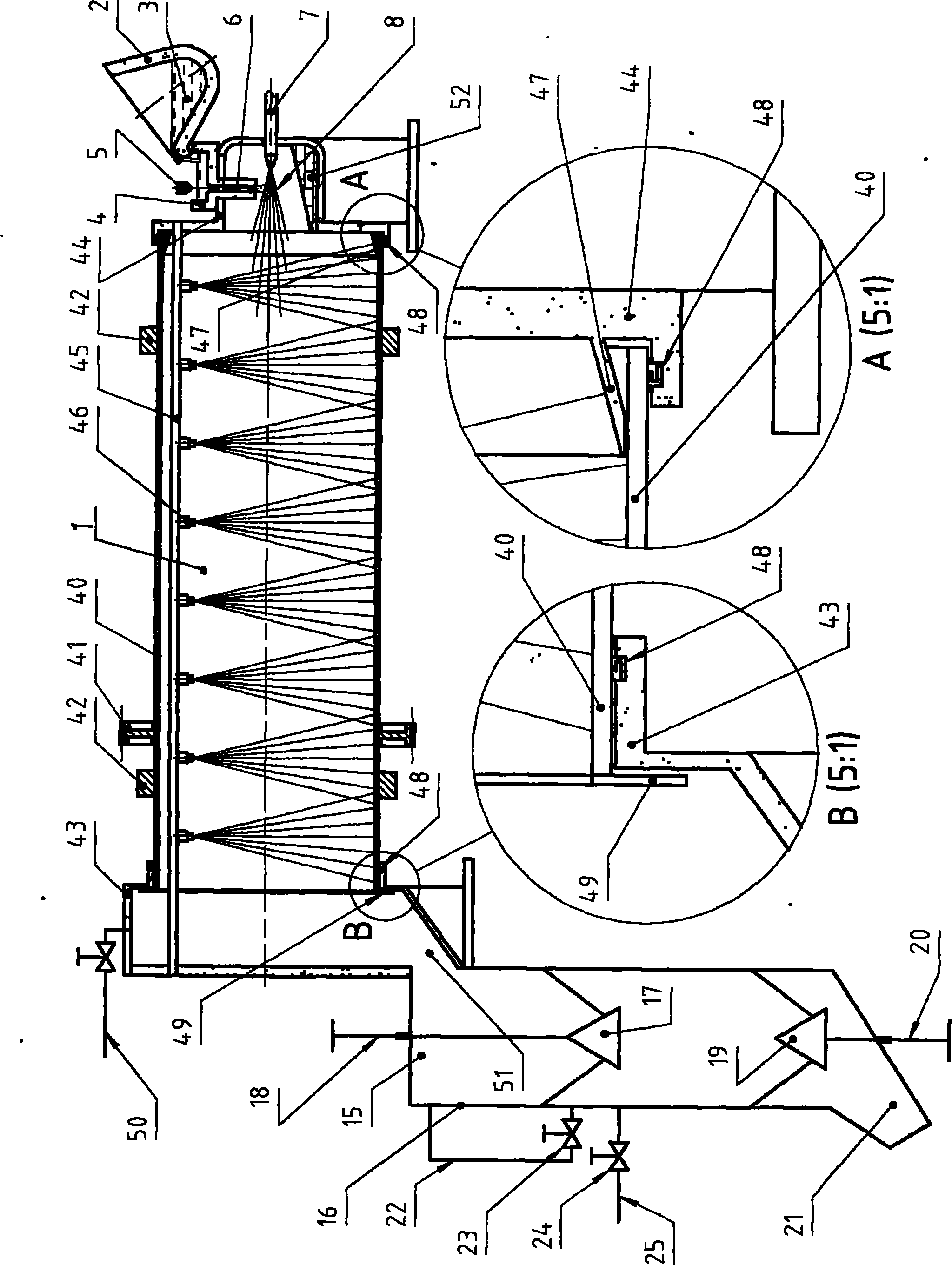

[0087] Example 3, such as image 3 shown.

[0088] This embodiment is an improvement on the basis of Embodiment 1 and Embodiment 2. The main improvement point is that: the closed space includes the space formed by the inner volume of the drum, and the complete solidification of the liquid slag, calculated by weight percentage, at least 10% is finally completed in this space.

[0089] exist image 3 Among them, 40 is the drum, 41 is the driving gear of the drum 40, 42 is the rolling ring of the drum 40, as for the supporting wheel and the rotary driving device of the drum 40, etc., they are not shown in the figure, 43 is the discharge end seat, 44 45 is a fixed beam erected on the inside of the drum 40, and facilities such as nozzle 46 (actually a nozzle group), detection probes, etc. are installed on the beam, and 47 is a protective plate at the blowing end, which can be Fixed on the blowing end seat 44, 48 is a seal, which can be a variety of finished parts with standard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com