Gas sample acquisition and analysis device for coal mine gob

A technology for collecting and analyzing gobs, applied in mining devices, mining equipment, earthwork drilling, etc., can solve problems affecting the accuracy of gas sample analysis in gobs, adding current lines and interfaces, and gas sample analysis errors, etc. Achieve the effects of avoiding errors, quick opening and closing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

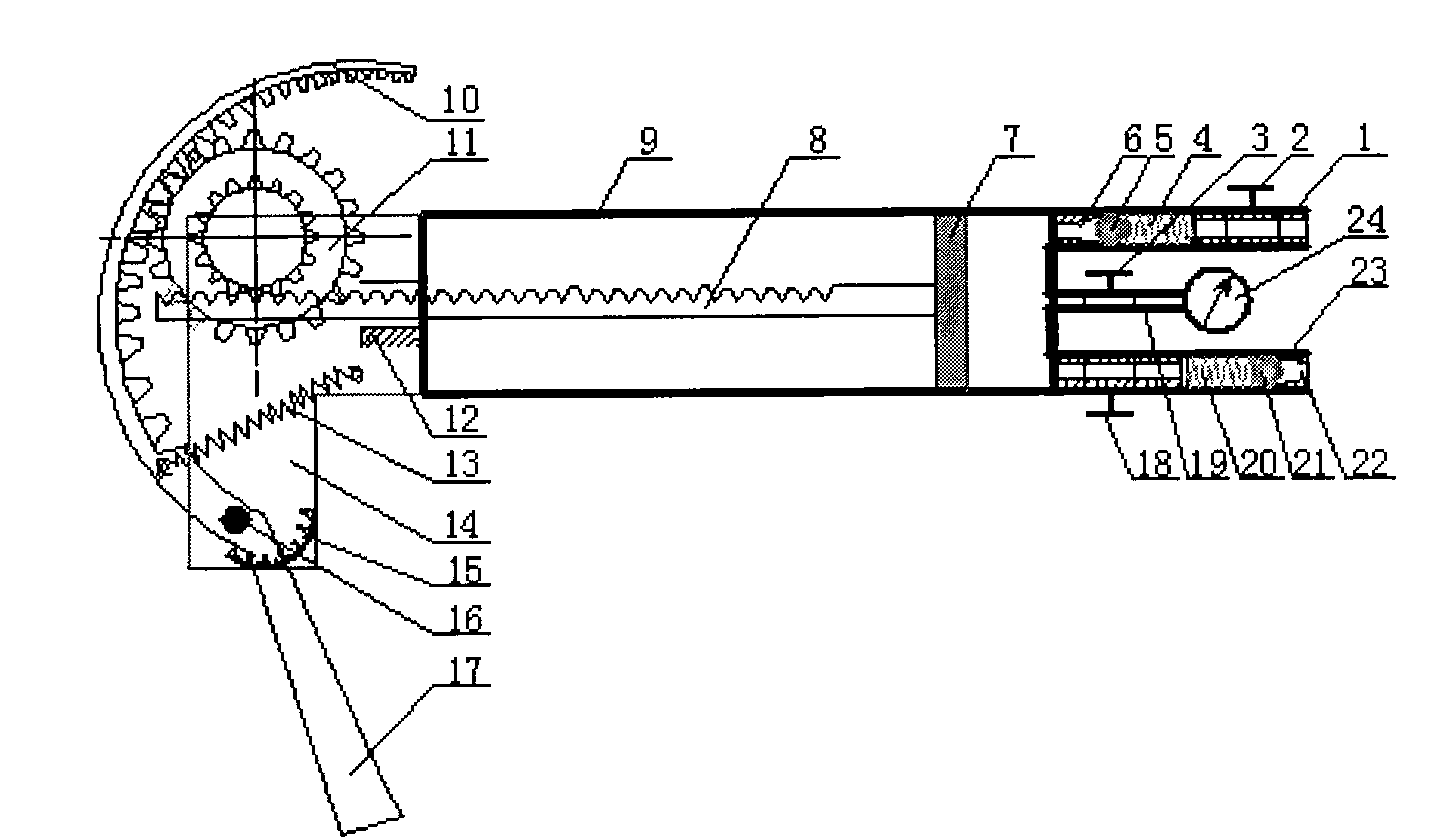

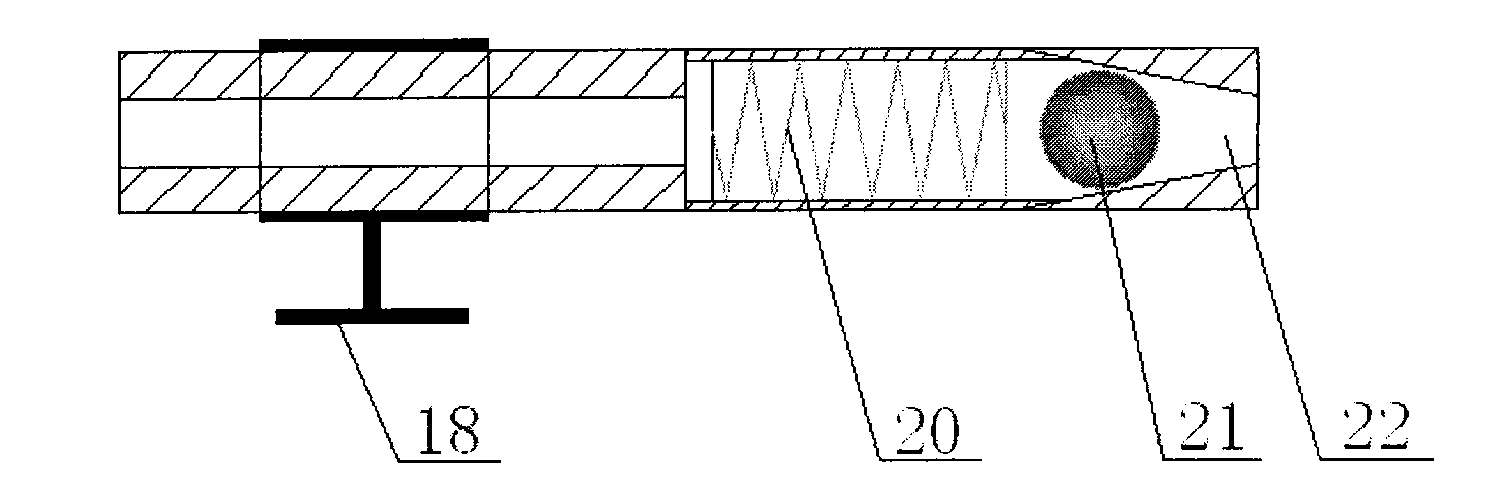

[0012] A gas sample collection and analysis device for underground coal mine goaf, which is composed of a gas sample collection part and a multi-parameter measuring instrument, that is, the gas sample collection part is a sleeve, and a piston is installed in the sleeve, and the piston and the plane gear rod Connected, the flat gear lever meshes with the small gear of the double-layer gear outside the sleeve, and the large gear of the double-layer gear meshes with the crank gear. When the crank gear moves clockwise through the handle, the double-layer gear also rotates clockwise. When the flat gear rod is driven by the small wheel of the double-layer gear to pump air outward; the intake valve automatically opens the valve under the action of the internal and external pressure difference to allow the gas sample to enter the sleeve.

Embodiment 2

[0014] After the device completes the pumping action, the spring will recover its deformation, and pull the crank gear to return counterclockwise, so that the crank gear drives the double-layer gear to move counterclockwise, and the double-layer gear pushes the flat gear rod to move downward, and the intake valve will move downward due to the pressure. The differential action is automatically closed, and the outlet valve is automatically opened to complete the exhaust process.

Embodiment 3

[0016] Before the gas sample collection device collects and analyzes gas samples, the inlet pipe is connected to the bundle pipe embedded in the goaf, and the outlet pipe is emptied. The gas is discharged, and then the gas sampling bag is connected to the gas outlet pipe, and the exhaust sample is drawn again until the gas sampling bag is full of gas samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com