Siphon sluicing method

A technology of siphon and water drift, applied in drainage, earthwork drilling, safety devices, etc., can solve problems such as low work efficiency and slow drainage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

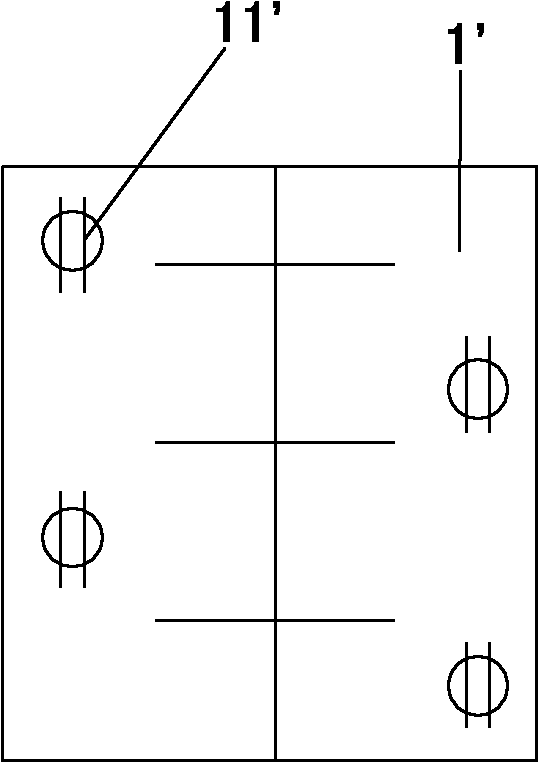

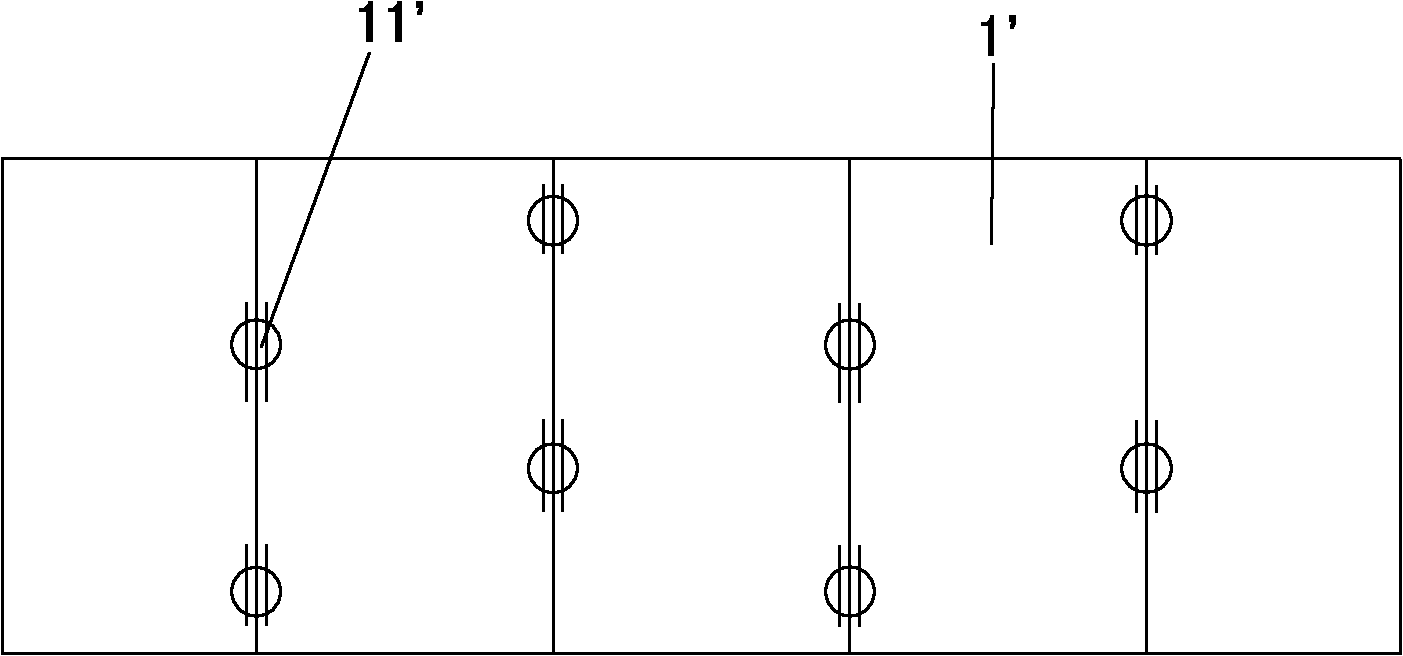

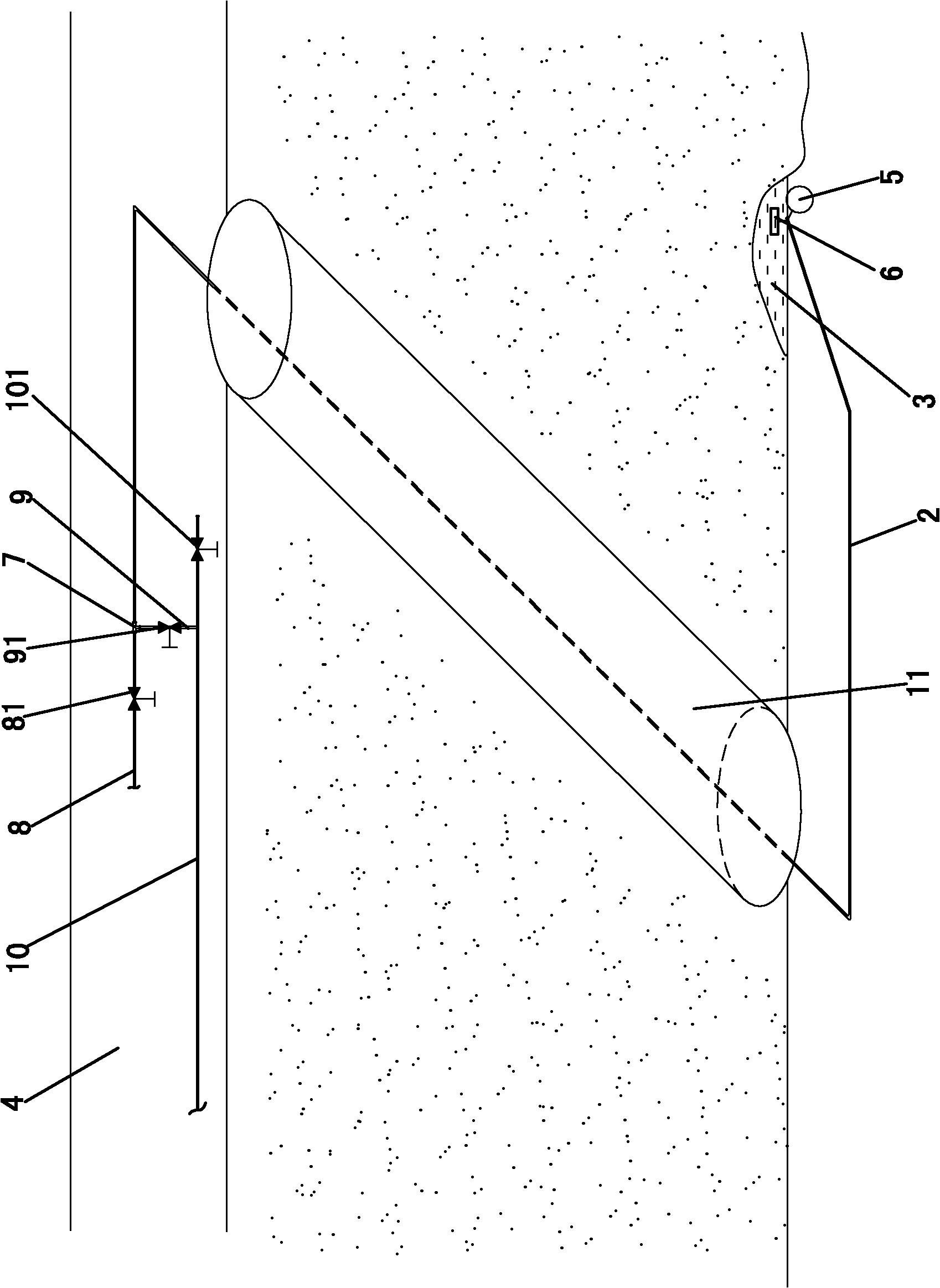

[0016] see image 3 As shown, the steps of the siphon drainage method of the present invention are: at first when tailings are filled in the stope, a PVC drainage pipe 2 with a diameter of 60mm is erected in the pedestrian drainage well 1, and the pedestrian drainage well 1 is a steel reel, steel coil The barrel is provided with a drain hole (not shown in the figure), and the drain pipe 2 passes through the steel drum, and one end of the drain pipe 2 is put into the stope 3, and the other end is put into the horizontal ditch of the mining roadway 4, and put The 2 ends of the drainage pipe entering the stope 3 are tied with a water float 5 and a weight 6. The water float 5 adopts a floating ball, and the weight 6 adopts a wooden pile of about 10 jin. One end of the through pipe 7, the second end of the three-way pipe 7 is connected to the second drain pipe 8, the second drain pipe 8 is provided with a second valve 81, the third end of the three-way pipe 7 is connected with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com