High-concentration bag filling process method and device

A process method and high-concentration technology, applied in the field of high-concentration bag filling process and device, can solve the problems of low concentration of fine-grained soil, uneven soil stirring, low bag filling efficiency, etc. The level of automation and the effect of reducing the intensity of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

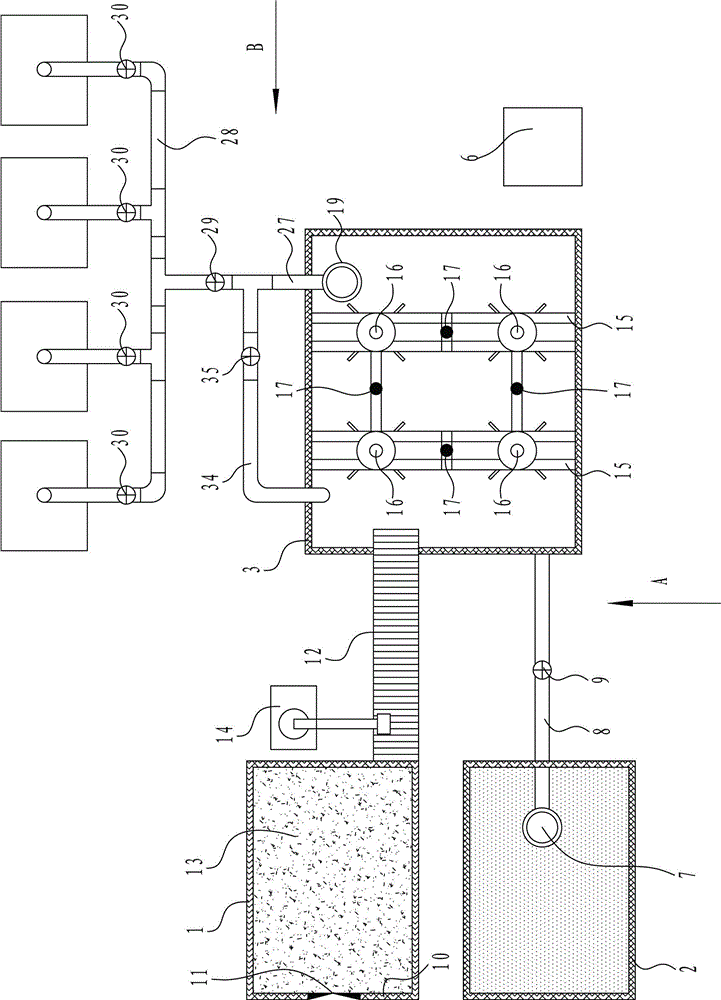

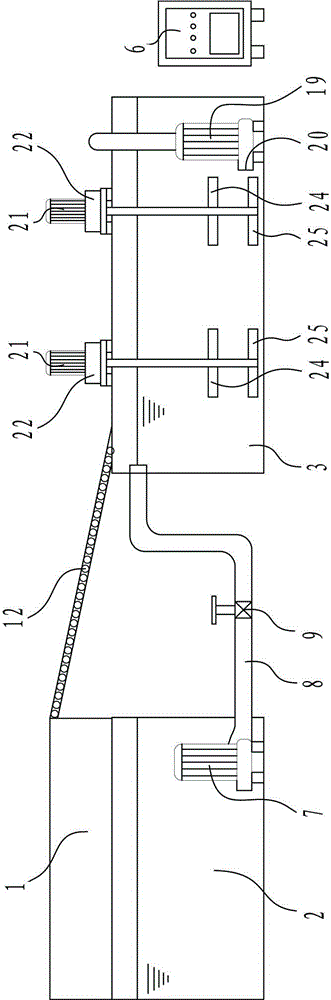

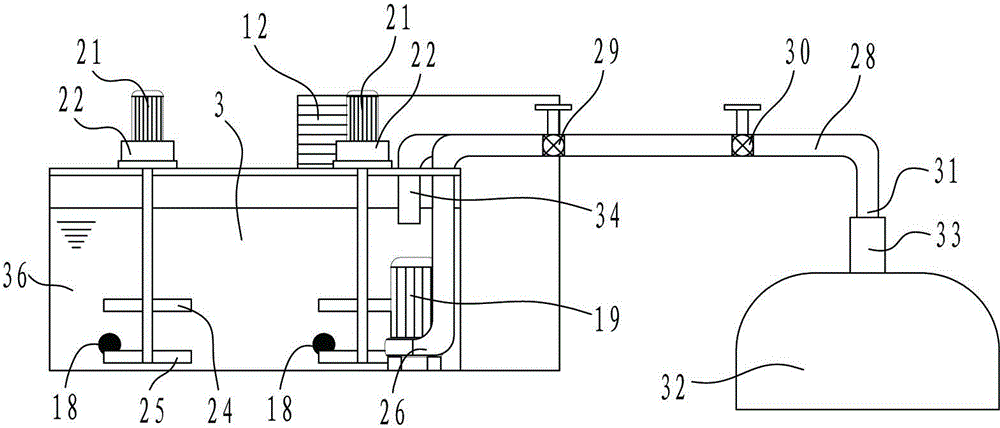

[0025] refer to figure 1 A high-concentration bag filling device according to the present invention includes a material storage tank 1 , a water supply tank 2 and a slurry mixing tank 3 . Both the material storage tank 1 and the water supply tank 2 are arranged near the slurry mixing tank 3 .

[0026] The water supply pool 2 is a rectangular concrete groove, the water supply pool 2 has a built-in submersible pump 7, the submersible pump 7 communicates with the pipeline 8, and the pipeline 8 communicates with the pulp mixing tank 3, and the pipeline 8 is equipped with Valve 9.

[0027] The storage tank 1 is a rectangular concrete groove, and a height-adjustable overflow weir 11 is placed on the wall body 10 around the storage tank 1 .

[0028] The slurry mixing tank 3 is a square concrete groove. Between the slurry mixing tank 3 and the storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com