Membrane valve carbon canister

A diaphragm valve and carbon canister technology, applied in the direction of diaphragm valves, diaphragms, valve devices, etc., can solve the problems of low selectivity of engine operating conditions, reduced reliability, and spring force that cannot be too large, so that it is not easy to operate errors , Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

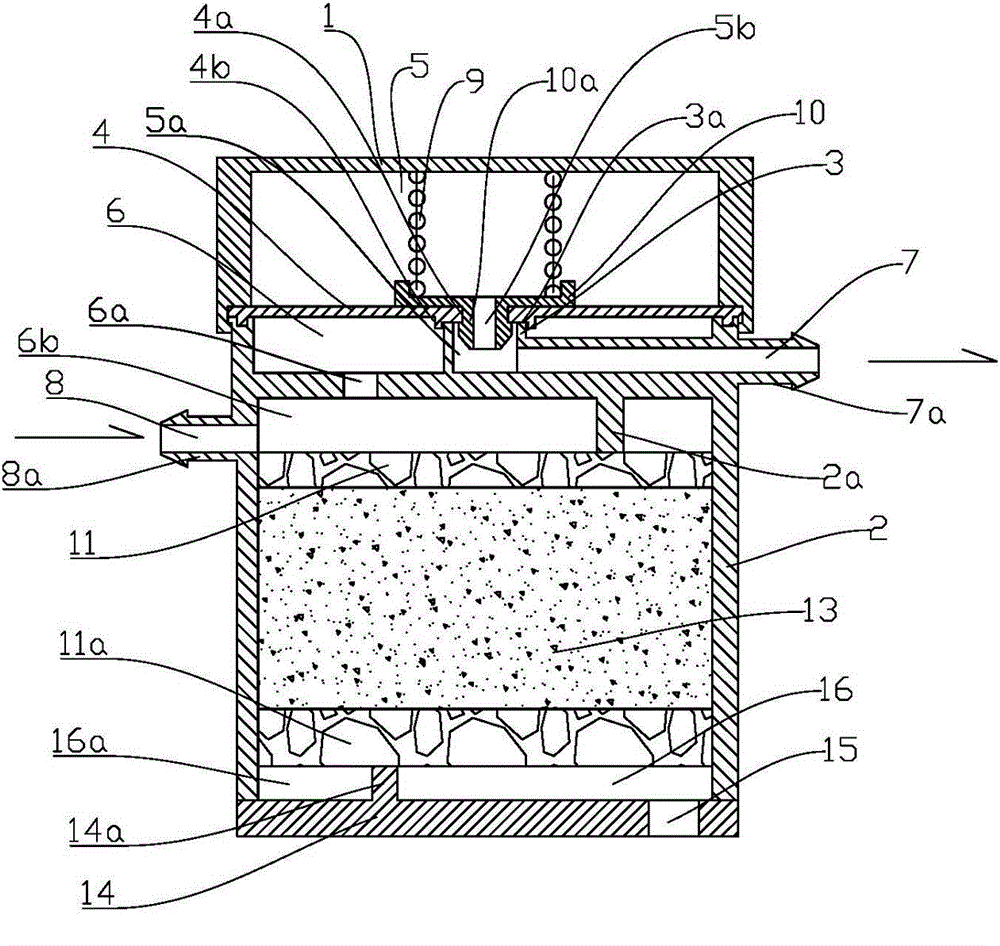

[0021] As shown in the figure, it is a cross-sectional view of the first embodiment provided by the present invention. Diaphragm valve canister main components include: upper body 1, lower body 2, valve seat 3, diaphragm 4. The diaphragm 4 and the valve seat 3 separate the space formed by the upper body 1 and the lower body 2 into a vacuum chamber and an oil-gas chamber 6 . The upper body 1 and the lower body 2 are usually made of plastic and other materials, and they can be connected by means of elastic fastening, screws, welding, etc.

[0022] The vacuum chamber includes a first vacuum chamber 5 and a second vacuum chamber 5a, the second vacuum chamber 5a is in communication with the desorption channel 7, and the lower body includes a desorption nozzle 7a surrounding the desorption channel 7.

[0023] The diaphragm 4 includes a spring seat 10, the spring seat 10 includes a protrusion 10a for positioning between the diaphragm 4, the protrusion 10a can be a rotating body with...

Embodiment 2

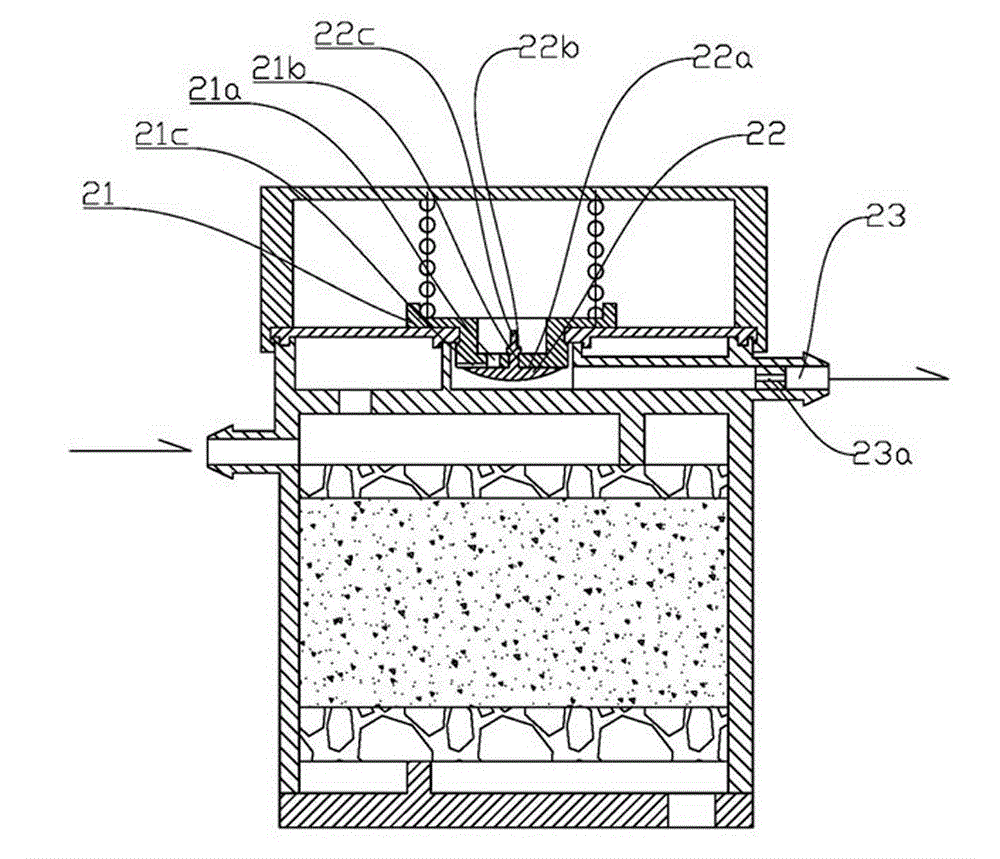

[0031] Such as figure 2 A cross-sectional view of the second embodiment provided by the present invention is shown. Parts not particularly marked are the same as in Example 1, and repeated parts have the same labels. The main difference with Embodiment 1 is that this embodiment is provided with a check valve between the first vacuum chamber 5 and the second vacuum chamber 5a. Such as figure 2 As shown, this one-way valve is a common umbrella valve, including an umbrella valve body 22 and a valve seat 21, the umbrella valve body 22 is provided with a valve stem 22c and a spherical protrusion 22b, and the valve seat 21 includes a central hole 21b and a surrounding The flow hole 21a arranged in it, the spherical protrusion 22b passes through the middle hole 21b to reach the other side of the valve seat 21 through elastic deformation, and then provides sealing elastic force for the umbrella valve, so that the umbrella valve body 22 covers the flow hole 21a, thereby preventing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com