Method for reclaiming heat of ventilated gas oxidation device

A ventilation gas and oxidation device technology, which is applied in the field of coal mine gas control and emission reduction, can solve the problems of high self-sustaining concentration of the oxidation device, low heat transfer efficiency of the heating surface, poor adaptability of methane concentration, etc., and achieves simple structure, convenient maintenance, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

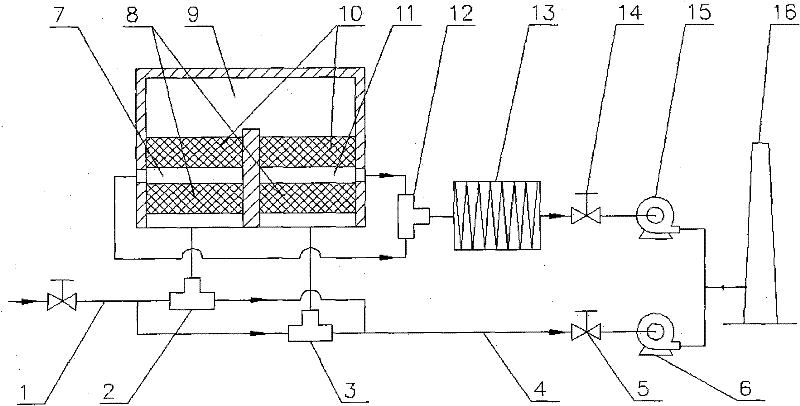

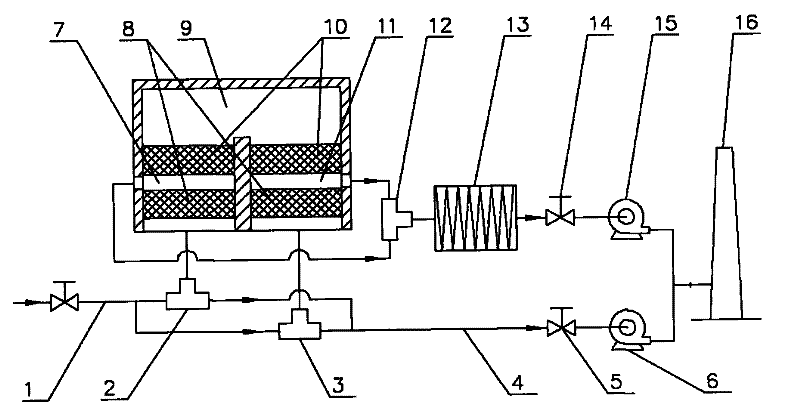

[0008] figure 1 As an embodiment of the present invention, the ventilation gas enters the ceramic heat storage material (8) in the low-temperature section through the air inlet pipe (1) and the three-way reversing valve A (2) for preliminary preheating, and passes through the air extraction cavity A (7 ) enters the high-temperature section of the ceramic heat storage material (10) to preheat again, and then enters the oxidation chamber (9) of the oxidation device for oxidative decomposition. The high-temperature flue gas after the methane oxidation of the ventilated gas first enters the ceramic heat storage material (10) in the high-temperature section for preliminary cooling, and the temperature drops to 450°C-750°C and enters the air extraction cavity B (11). Part of the flue gas in the air extraction cavity B (11) enters the ceramic heat storage material (8) in the low temperature section to be cooled again, and then passes through the three-way reversing valve B (3), the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com