Ventilated gas oxidizing system capable of recovering heat energy

A technology of ventilation gas and oxidation system, which is applied in the directions of heat generation by exothermic chemical reaction, heat generation by non-combustion exothermic chemical reaction, heating fuel, etc. Maintenance difficulties and other problems, to achieve the effects of strong adaptability, reduced wall heat dissipation, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

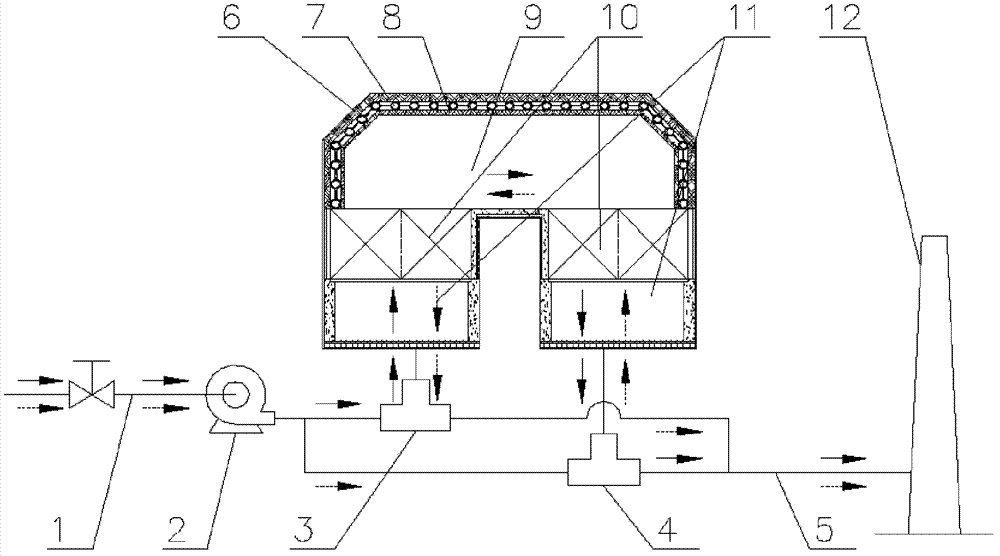

[0018] figure 1 It is the first embodiment of the present invention. The ventilation gas enters the ceramic heat storage material 10 for preheating through the air inlet pipe 1, the blower 2, the three-way reversing valve A3, and the rectifying chamber 11, and then enters the oxidation chamber 9 for oxidative decomposition (airflow flow The direction is indicated by the solid arrow in the figure). Part of the heat released after methane decomposition and oxidation passes through the internal insulation layer 8 and is absorbed by the heat exchange surface 7 of the model wall; this part of heat is related to the concentration of methane in the ventilation gas, accounting for 0% to 80% of the total heat released by the oxidation of methane in the ventilation gas %; In the outer wall of the oxidation chamber 9 and the inner side of the mode wall heat exchange surface 7, an internal heat insulation layer 8 is arranged, which is made of a refractory material, and is used to control ...

Embodiment 2

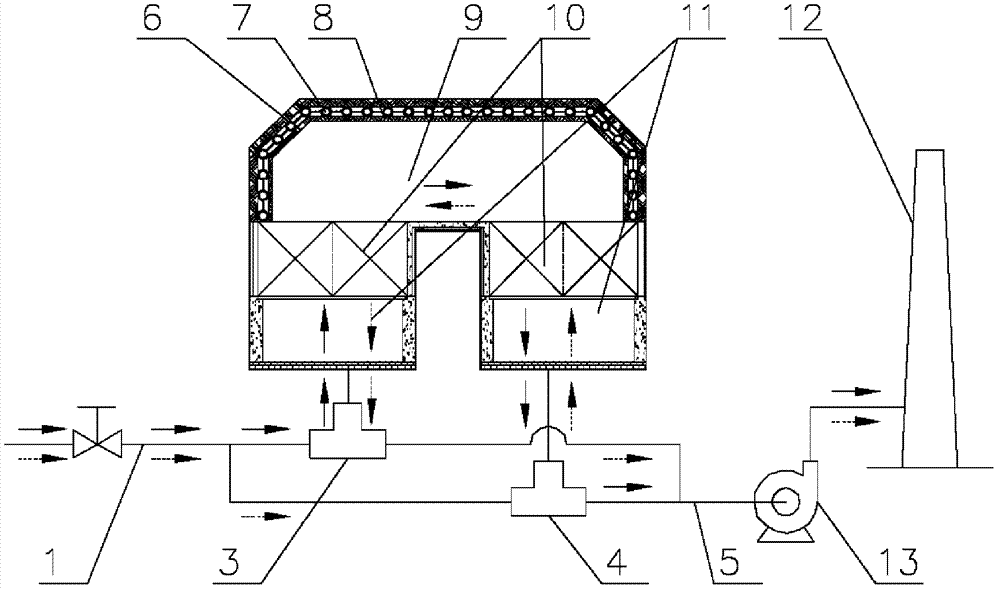

[0020] figure 2 It is the second embodiment of the present invention. The ventilation gas enters the ceramic heat storage material 10 to preheat through the air inlet pipe 1, the three-way reversing valve A3, and the rectifying chamber 11, and then enters the oxidation chamber 9 for oxidative decomposition (the flow direction of the airflow is shown in the figure indicated by the solid arrow). Part of the heat released after methane decomposition and oxidation passes through the internal insulation layer 8 and is absorbed by the heat exchange surface 7 of the model wall; this part of heat is related to the concentration of methane in the ventilation gas, accounting for 0% to 80% of the total heat released by the oxidation of methane in the ventilation gas %; on the outer wall of the oxidation chamber 9 and the inner side of the mode wall heat exchange surface 7, an internal heat insulation layer 8 is set, which is made of refractory material, and is used to control the heat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com