Nondestructive detection method for detecting damage of metal material

A metal material, non-destructive testing technology, applied in the direction of analyzing materials, material resistance, material analysis by electromagnetic means, etc., can solve the problems of poor universality, high requirements on the operation level of inspectors, cumbersome inspection steps, etc., and achieves simple operation. The effect of convenience, strong engineering practical value and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

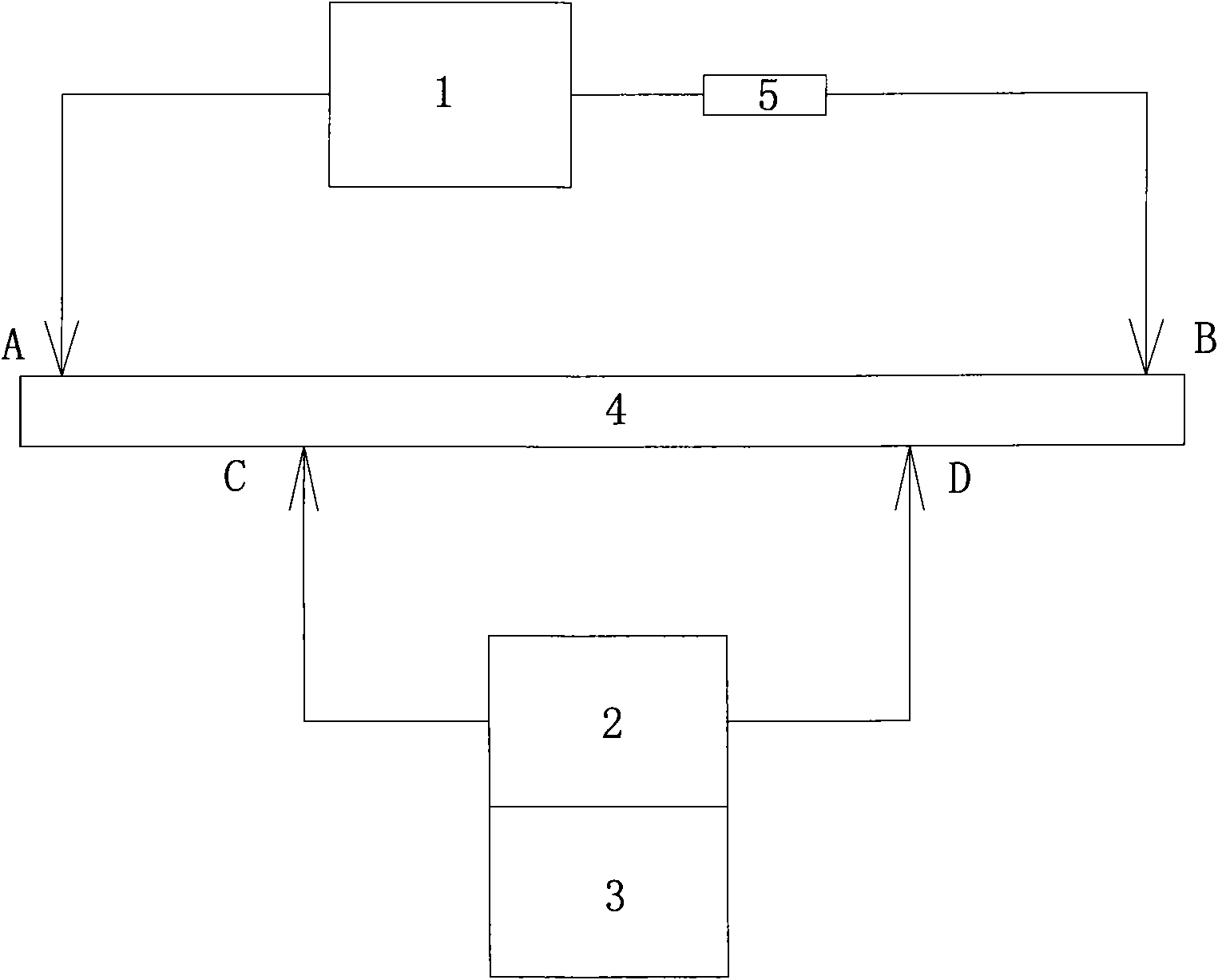

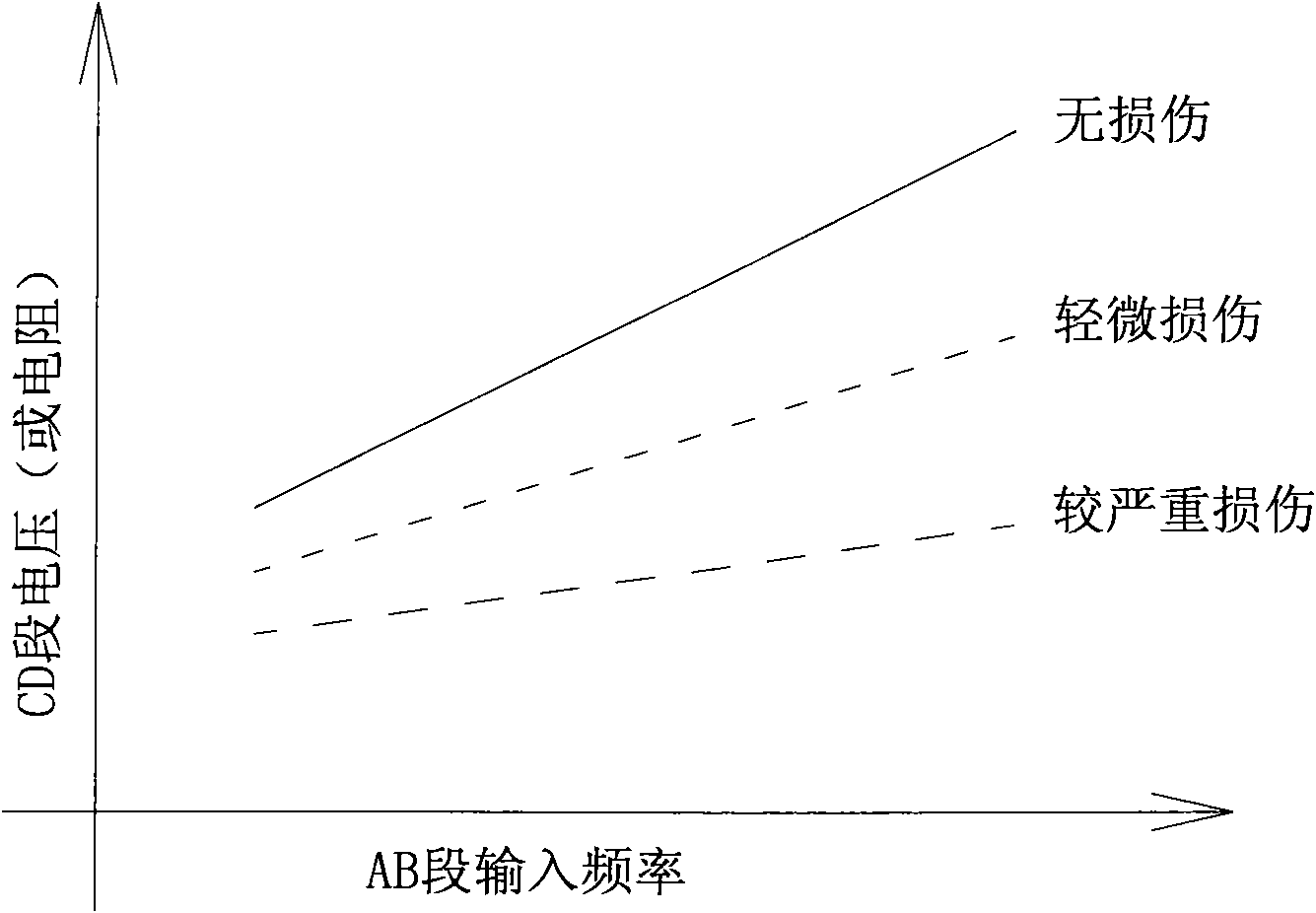

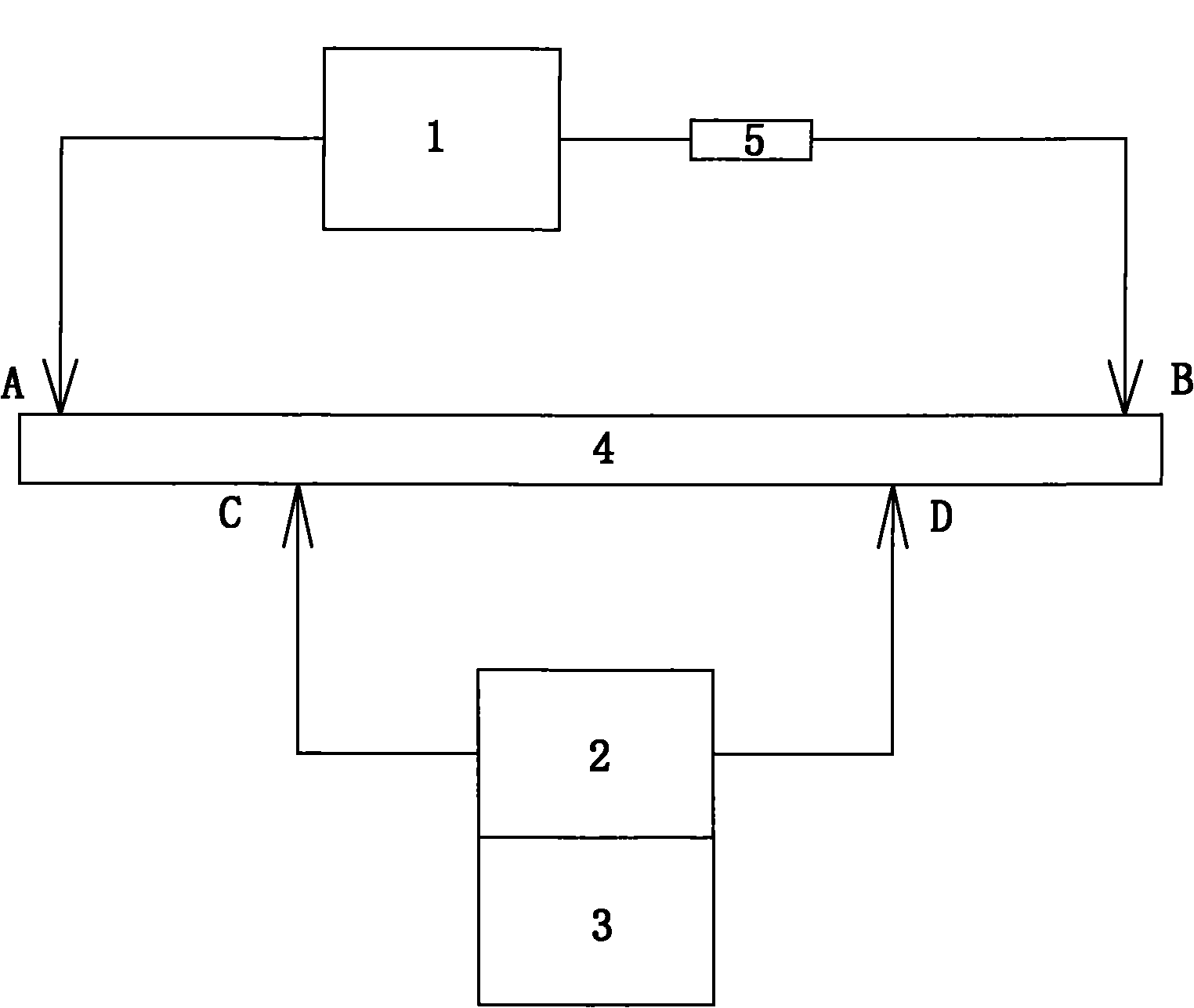

[0020] In order to better understand the shape, structure and characteristics of the present invention, preferred embodiments will be listed below and described in detail with reference to the accompanying drawings.

[0021] Principle of the present invention is as follows:

[0022] When a direct current flows through a conductor, the current density on the cross section is uniform and the same. When the alternating current passes through the conductor, the current distribution along the conductor cross-section is uneven, and the current density on the surface is larger, and the closer to the center, the smaller, especially when the frequency is high, the current is almost thin near the surface of the conductor. This is the skin effect phenomenon (or called skin effect, skin effect, skin effect).

[0023] The distance that the eddy current penetrates into the conductor is called the penetration depth, and the penetration depth when the eddy current density decays to its surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com