Systems and methods to predict fatigue lives of aluminum alloys under multiaxial loading

A fatigue life, aluminum alloy technology, applied in the direction of testing metals, measuring devices, instruments, etc., can solve the problems of shortened fatigue life of aluminum alloys, accelerated fatigue crack formation and extension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

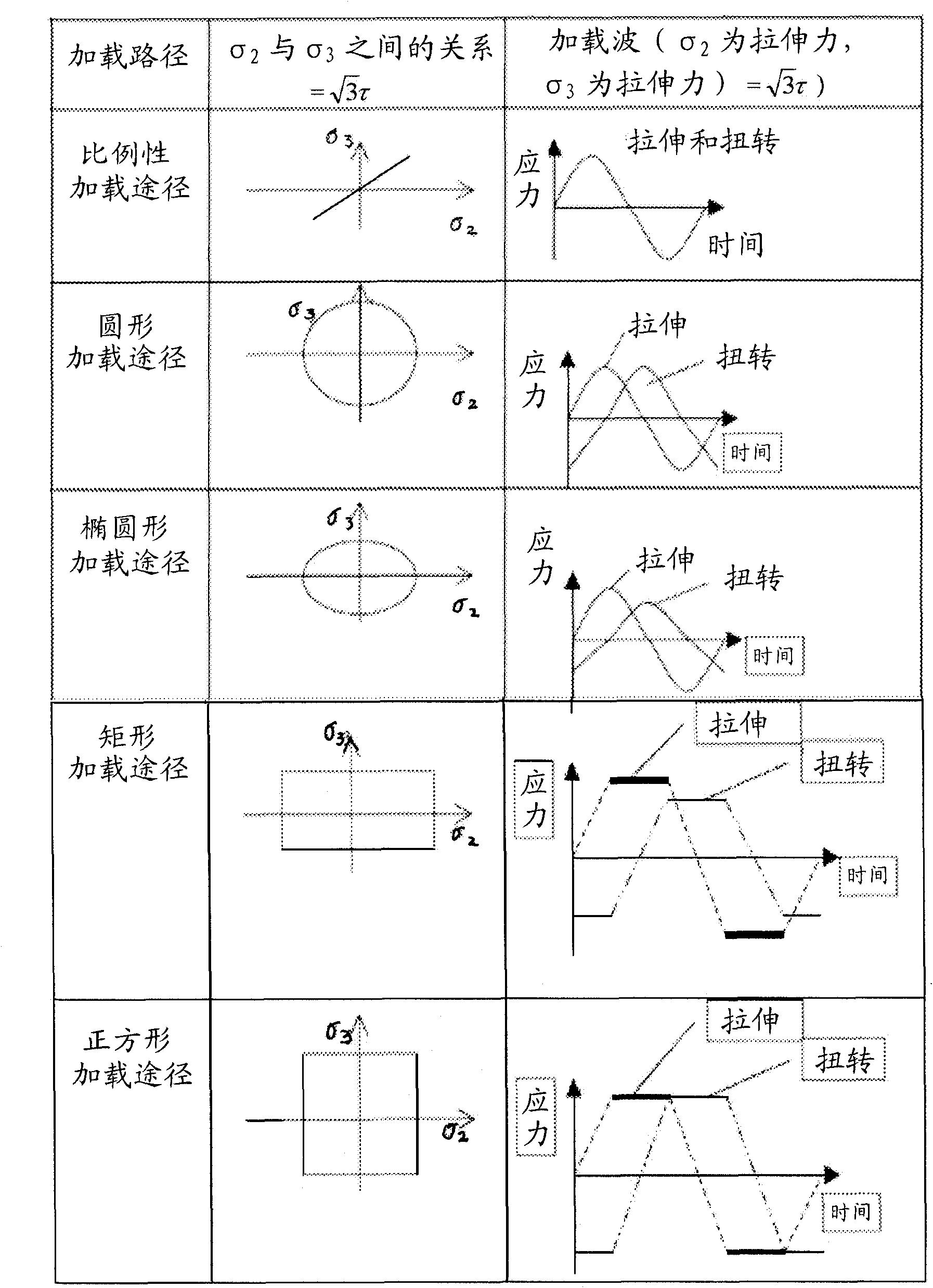

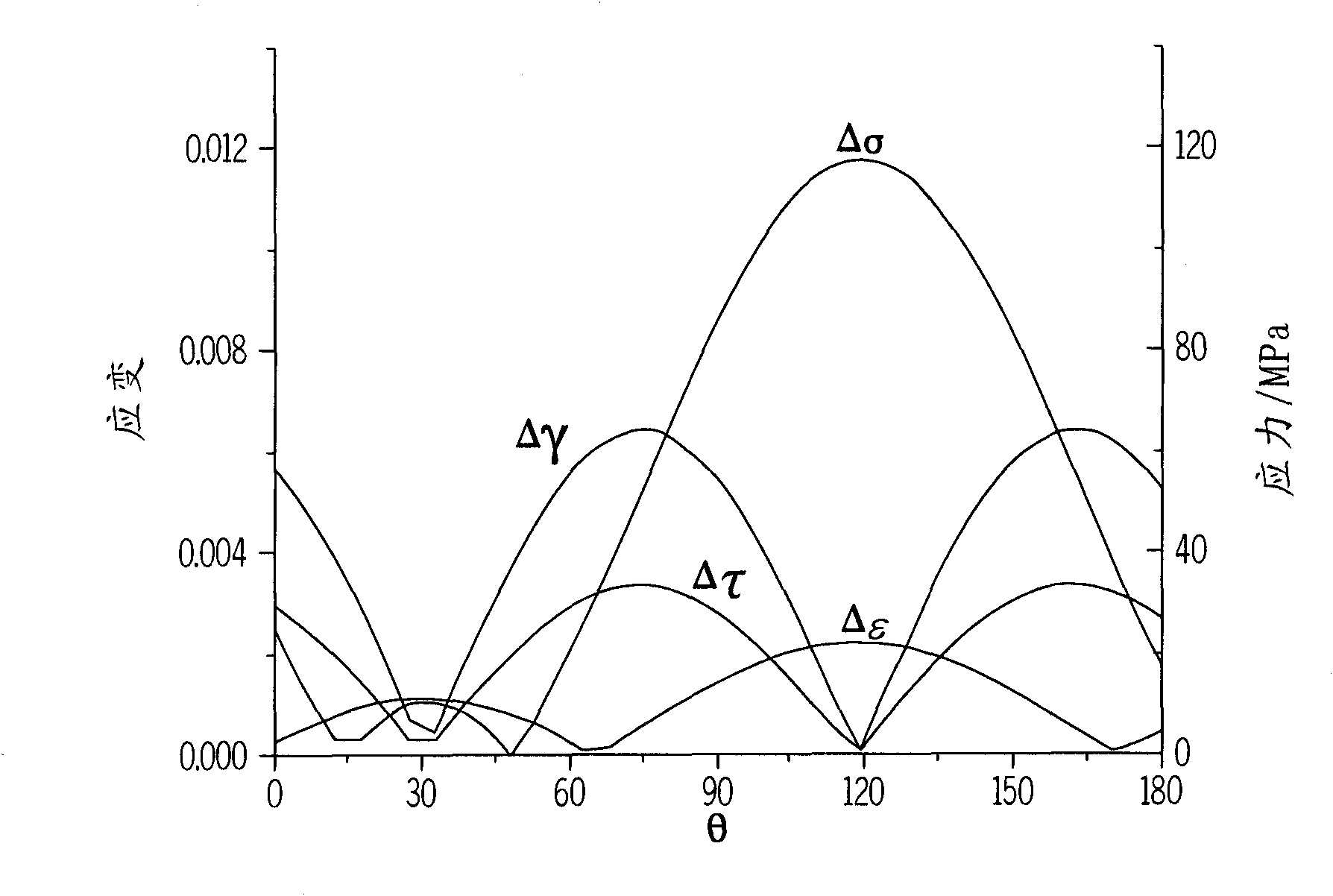

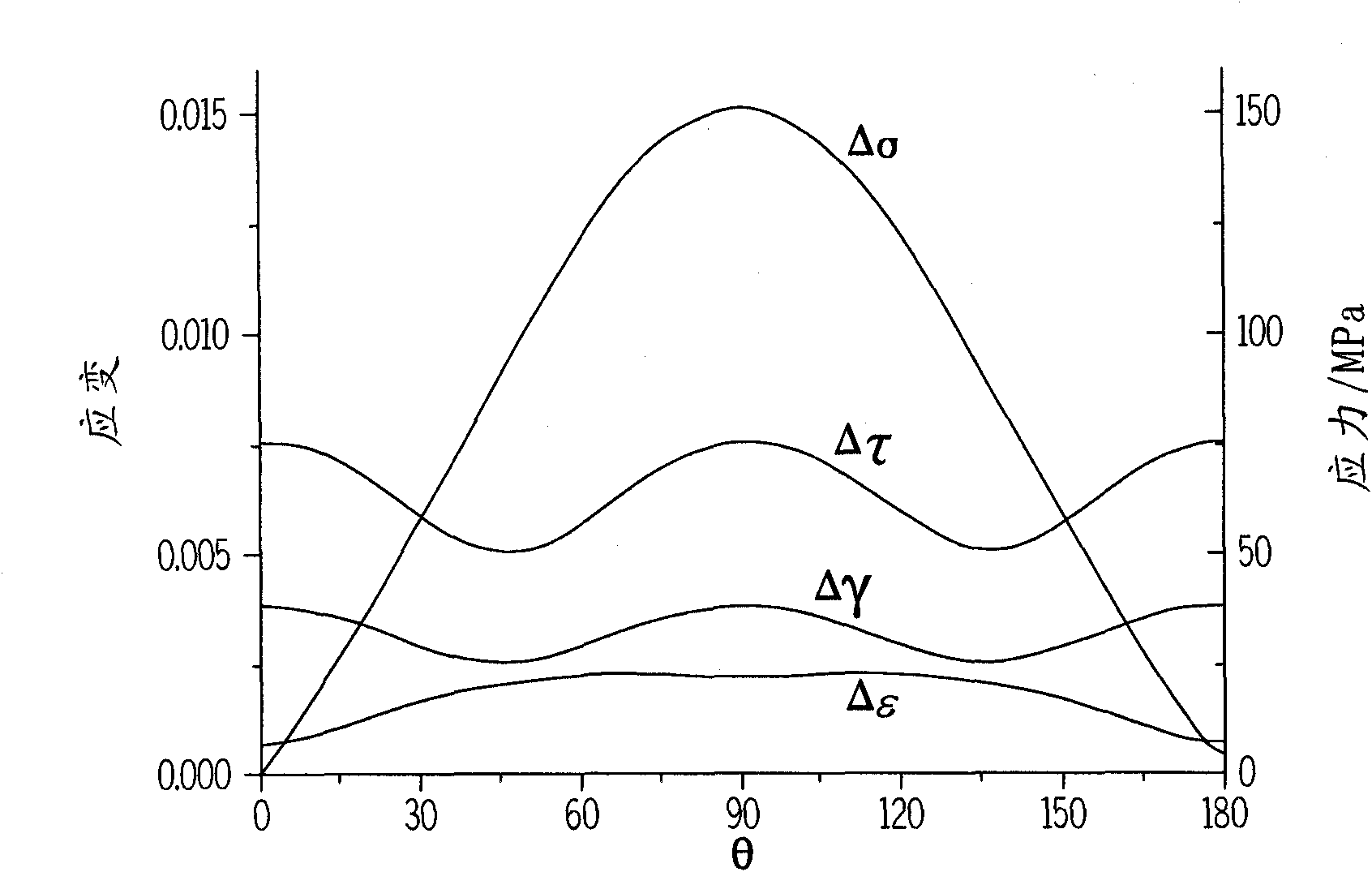

[0132] Embodiments of the present invention generally relate to systems, methods, and articles for predicting the fatigue life of aluminum alloys under cyclic multiaxial loading. As described above, the fatigue life under at least one of multiaxial proportional and non-proportional loading can be predicted using the embodiments of the present invention. In this way, it is conceivable that these embodiments are operable to predict the fatigue life of an aluminum alloy under at least one of multiaxial proportional or non-proportional loading.

[0133] The embodiments respectively include and / or utilize at least one (but not limited to one) fatigue life model based on micromechanics to process at least one of the following: information related to aluminum alloy, and information related to aluminum alloy Present information related to the stress state to predict the fatigue life of the aluminum alloy. As used herein, "aluminum alloy" refers not only to the alloy itself, but also to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com