Movement mechanism for linear multidigit ionization chamber

A technology of motion mechanism and ionization chamber, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of unfavorable maintenance, troublesome repair, and large space occupied by the treatment head, and achieve the effect of strong reliability and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

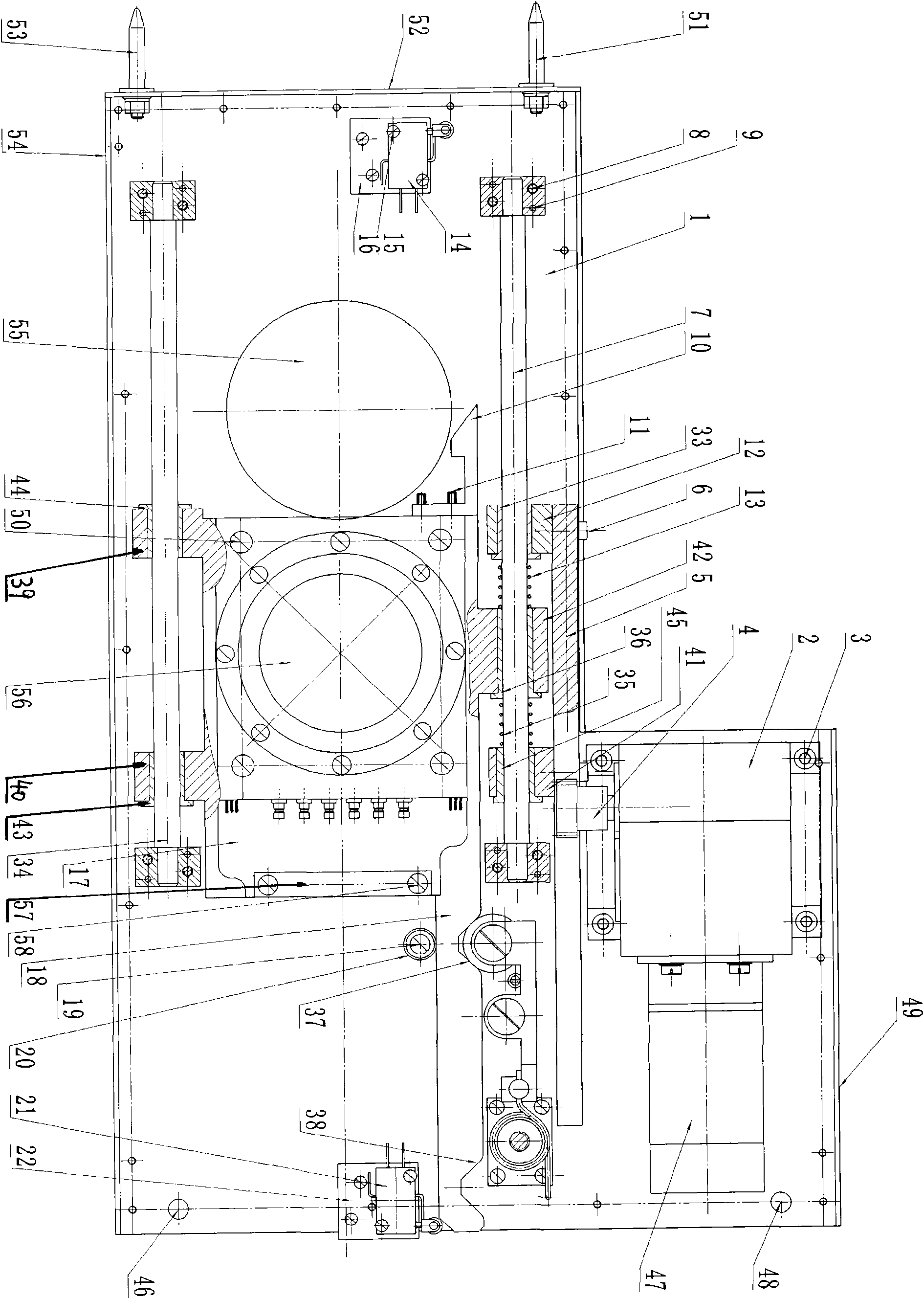

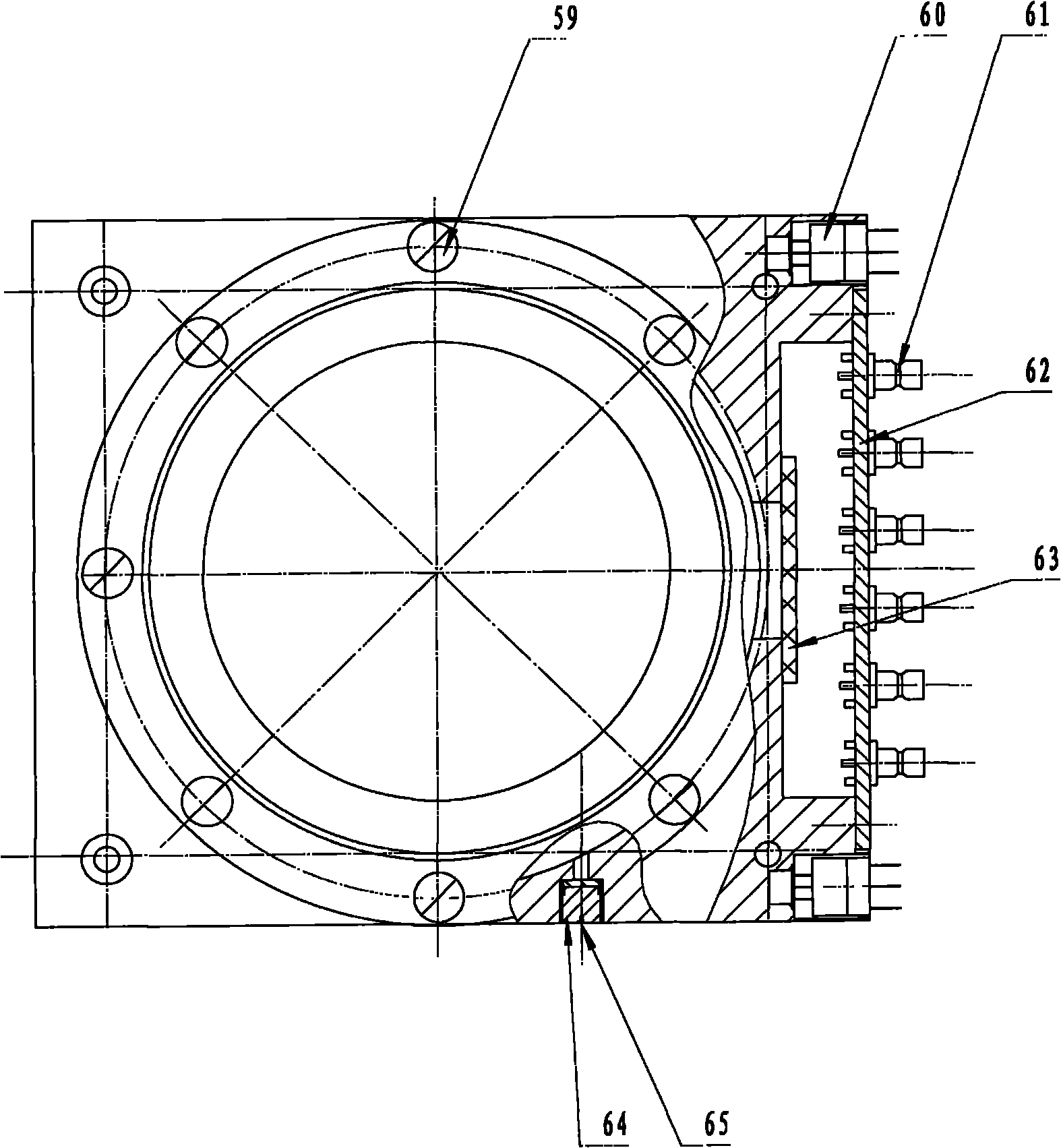

[0033] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme and accompanying drawings. An example is attached figure 1As shown, a linear multi-position ionization chamber movement mechanism in the present embodiment includes a base plate (1), a driving device (2), a transmission gear (4), a transmission rack (5), a guide shaft 1 (7), a guide Shaft II (34), load frame (17), micro switch I (21) and micro switch II (14), compression spring I (13), compression spring II (35), connection block I (12), connection Block II (41), connecting block III (42), connecting block IV (39), connecting block V (40), sliding copper sleeve I (33), sliding copper sleeve II (45), sliding copper sleeve III (36) , sliding copper sleeve IV (44), sliding copper sleeve V (43), stop pin (19), limit lever combination.

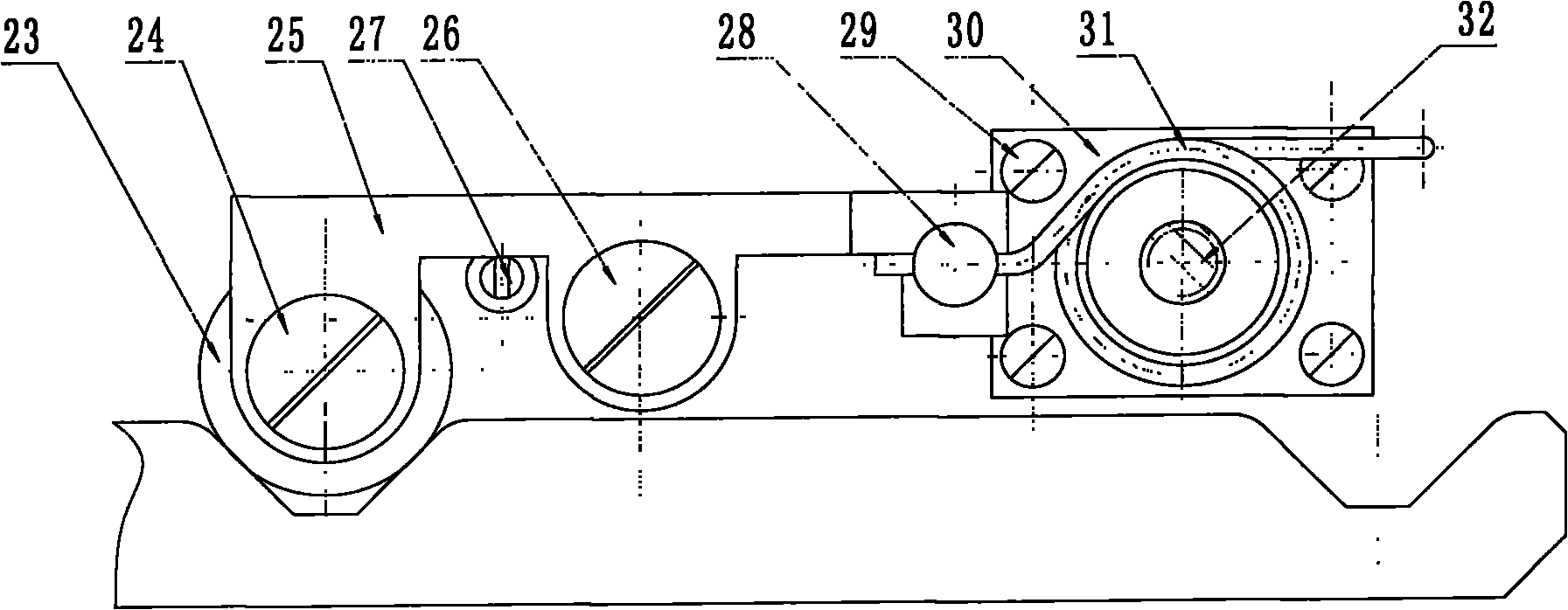

[0034] The limit lever combination includes: positioning bearing (23), universal swivel head (28), intermediate pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com