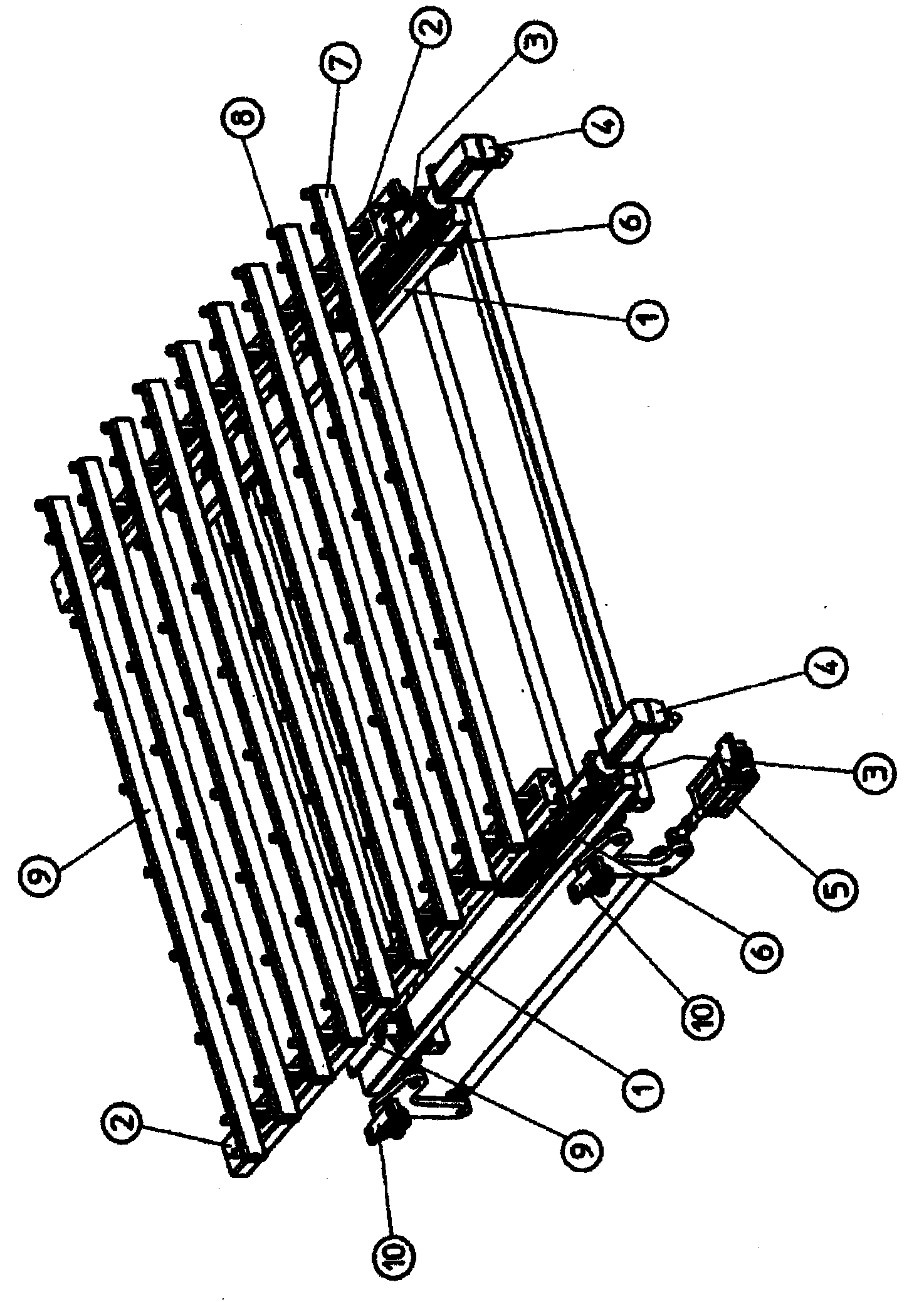

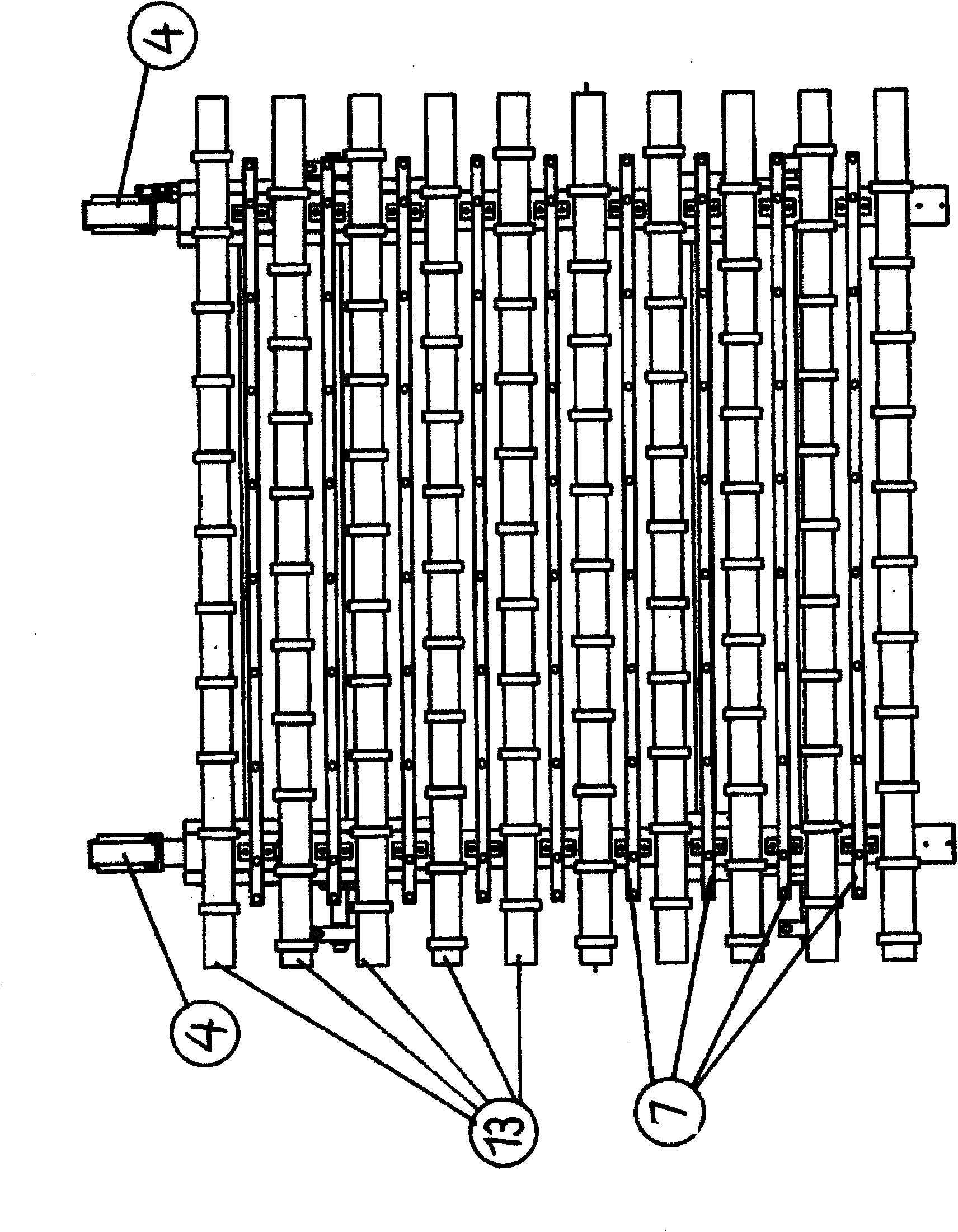

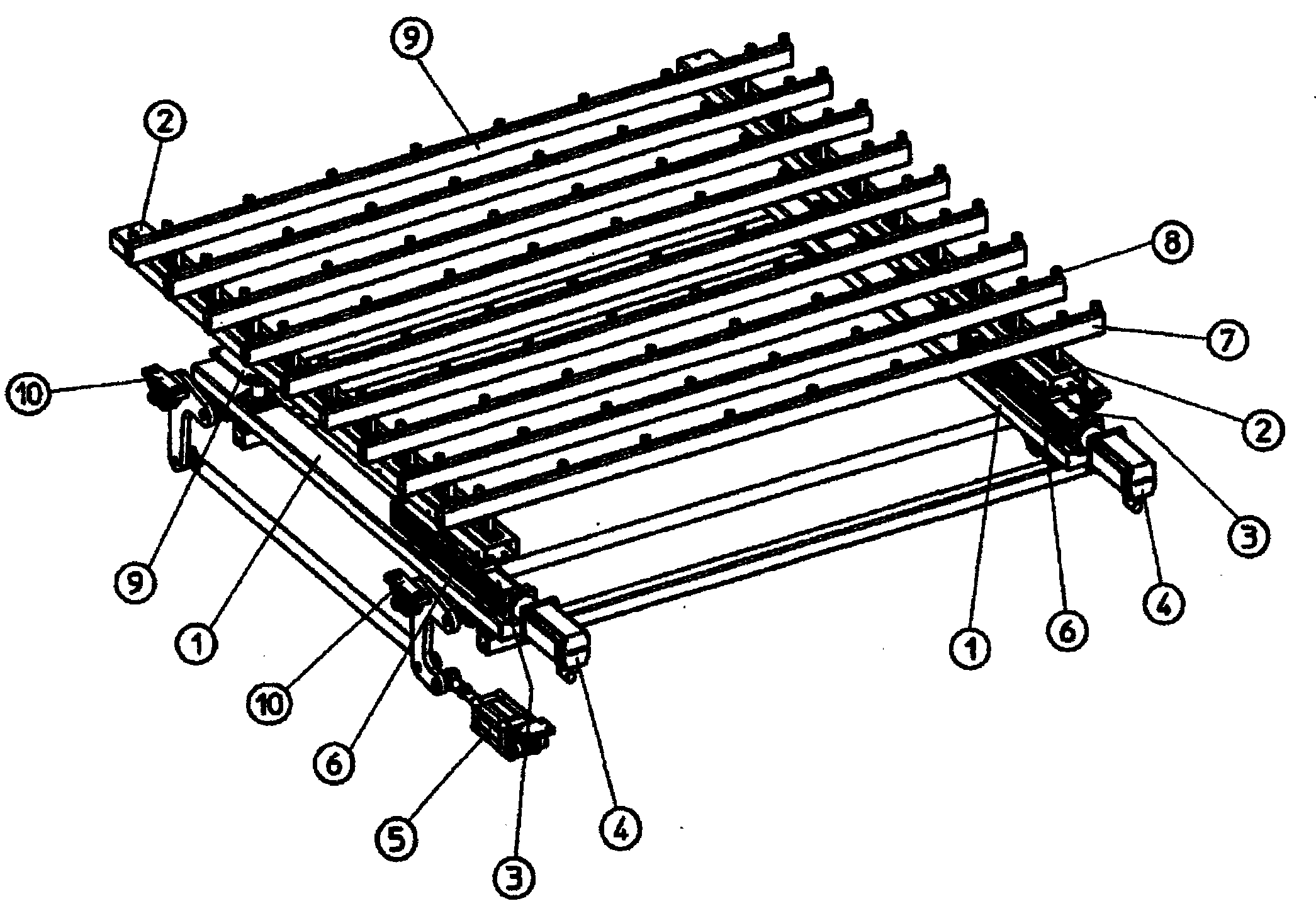

Apparatus and method for orienting shock-sensitive glass plates in ultra clean rooms

A glass sheet, sensitive technology, used in transportation and packaging, lighting and heating equipment, furnaces, etc., to solve problems such as not being available

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A clean room, as used in microelectronics, has a plurality of graded areas with corresponding clean room classes. The clean room (class 10 and higher) is therefore surrounded by a separate area with the systems required for coating and structuring, in which the substrates are processed. The pumps required for vacuum technology are usually located in the substratum.

[0034] The access to the clean room is usually reached via a sequence of different clean room regions with descending clean room classes. A change of clothing is often required between different areas. To minimize contamination from things that come into contact with the floor, such as shoe soles, there are special sticky mats at each entrance. In addition to the entrance to the cleanroom itself via an airlock acting on people and materials, inside said airlock, in turn, a powerful air flow and filter system are swirled up and the particles present are drawn out so that no additional pollutants come from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com