Fluidizing cracking catalyst and method for reducing NOx emissions during fluid catalytic cracking

A fluidized cracking, catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of reducing, affecting product composition, and detrimental to refinery profits And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Although the present invention is not limited to any particular method of preparation, generally the granular NO reducing x The composition is prepared by the following process: to reduce NO at the end x A composition comprising at least 10.0 weight percent ferrierite and at least 5.0 weight percent binder material in an amount sufficient to form a composition comprising ferrierite, an optional zeolite component, an inorganic binder, and an optional matrix An aqueous slurry of the material, which is thereafter spray dried to form particles. The spray-dried particles are optionally dried at a sufficiently high temperature for a sufficient time to remove volatiles, for example at about 90°C to about 320°C for about 0.5 to about 24 hours. In a preferred embodiment of the invention, the aqueous slurry containing ferrierite is ground prior to spray drying to reduce the average particle size of the material contained in the slurry to 10 microns or less, preferably 5 microns ...

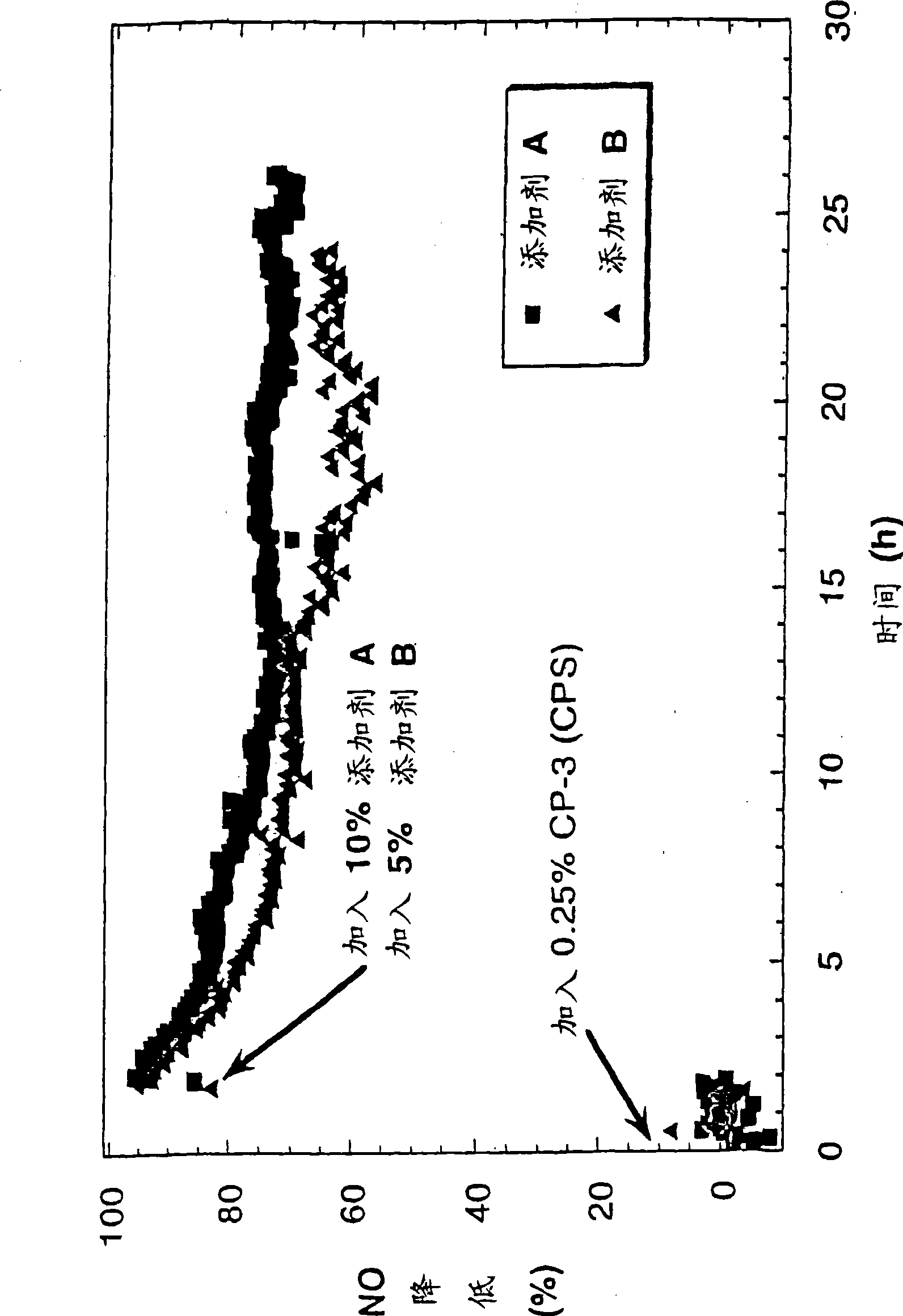

Embodiment 1

[0069] A composition comprising 40% ferrierite, 40% clay and 20% silica sol (Additive A) was prepared as follows. In the Drais mill will contain 29% ferrierite (SiO 2 / Al 2 o 3 =20) to an average particle size of less than 2.5 microns. A slurry of ground ferrierite (4160 g) was mixed with 1200 g Natka clay (dry basis) and 6000 g silica sol binder (30% solids). Silica sol binders were prepared from sodium silicate and acid alum. The catalyst slurry was then spray dried in a Bowen spray dryer. The resulting spray-dried product was washed with ammonium sulfate solution and then with water to give Na 2 Catalysts having an O level of less than 0.1 weight percent. The properties of the additives are shown in Table 1 below.

Embodiment 2

[0071] A composition comprising 75% ferrierite and 25% alumina sol (Additive B) was prepared as follows. An aqueous slurry was prepared containing 2174 g of aluminum chlorohydrol solution (23% solids), 1500 g (dry basis) of ferrierite (SiO 2 / Al 2 o 3 =20,Na 2 O+K 2 (0<0.2) and enough additional water such that the slurry contains approximately 40% solids. The slurry was ground in a Drais mill to an average particle size of less than 2.5 microns, then spray dried in a Bowen spray dryer. The spray dried product was calcined at 1100°F for 90 minutes. The properties of the catalyst are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com