Organic composite reinforcing steel bar rust inhibitor for reinforced concrete and method for preparing same

A technology of reinforced concrete and composite steel bars, applied in the organic composite steel bar rust inhibitor and its preparation, the field of organic steel bar rust inhibitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

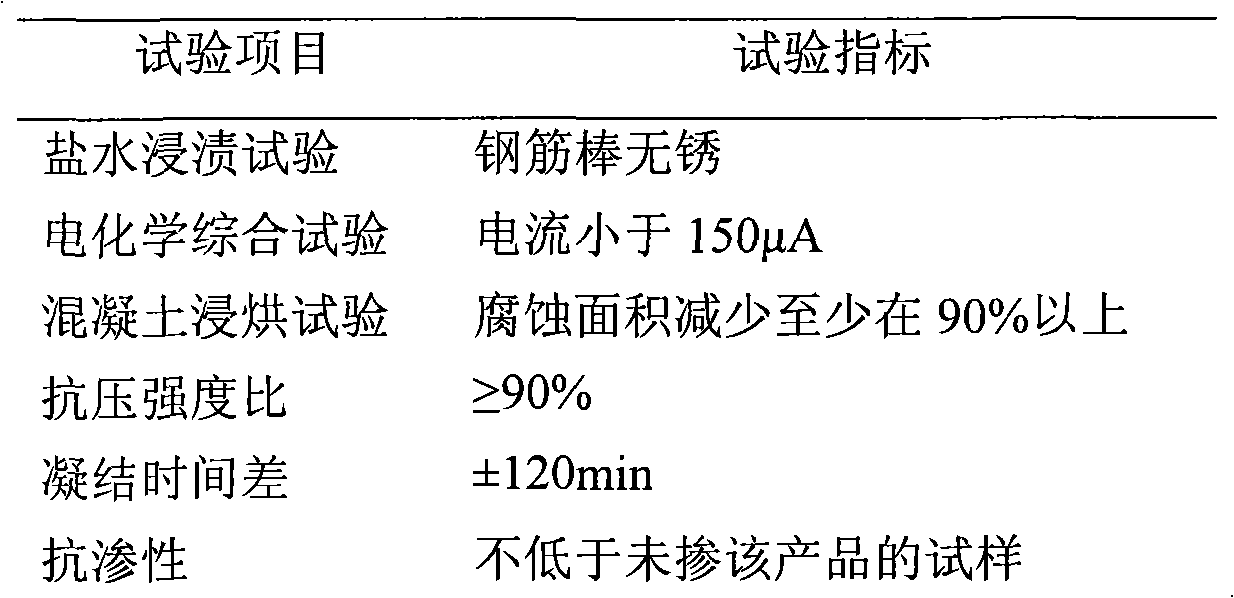

Problems solved by technology

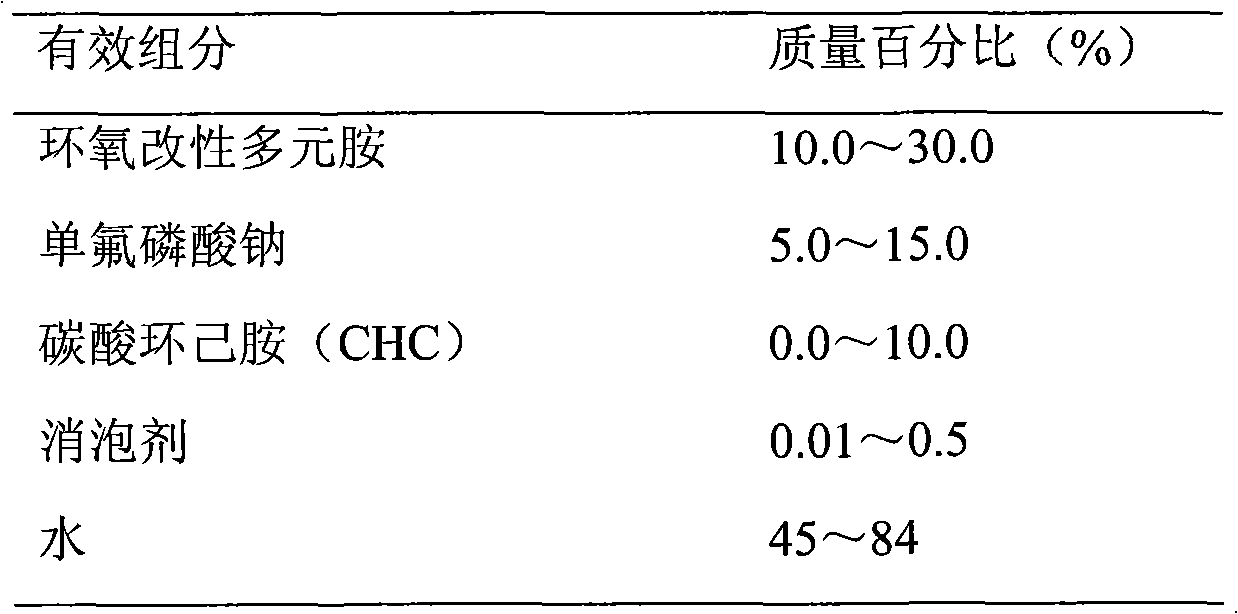

Method used

Image

Examples

Embodiment 1

[0017] Weigh 100g of epoxy-modified diethylenetriamine and put it into a glass container. When heated to 30°C, add 749g of water and 150g of sodium monofluorophosphate successively, and stir until the liquid is uniform; then add 1g of defoamer, fully Stir until the solids are uniformly dissolved, and then stand until clear to obtain a uniform liquid product.

Embodiment 2

[0019] Weigh 200g of epoxy-modified triethylenetetramine and add it to a glass container. When heated to 35°C, add 648.5g of water, 100g of sodium monofluorophosphate, and 50g of cyclohexylamine carbonate (CHC) successively, and stir until the liquid is uniform. state; then weigh 1.5g of defoamer, add it to a glass container, stir well until the solid is uniformly dissolved, and then stand until it becomes clear to obtain a uniform liquid product.

Embodiment 3

[0021] Weigh 300g of epoxy-modified tetraethylenepentamine and add it to a glass container. When heated to 40°C, add 545g of water, 50g of sodium monofluorophosphate, and 100g of cyclohexylamine carbonate (CHC) successively, and stir until the liquid is uniform. ; Then weigh 5.0g of defoamer, add it to the glass container, stir well until the solid is uniformly dissolved, and let it stand until it becomes clear to obtain a uniform liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com