Multi-disc brake

A technology of brakes and dynamic friction plates, which is applied to the types of brakes, axial brakes, and parts of brakes, etc., can solve the problems of limited fatigue stress increase range, fatigue fracture of brake half-shaft and half-shaft, and increased manufacturing costs, etc., to achieve Large braking torque, convenient maintenance, and the effect of reducing impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

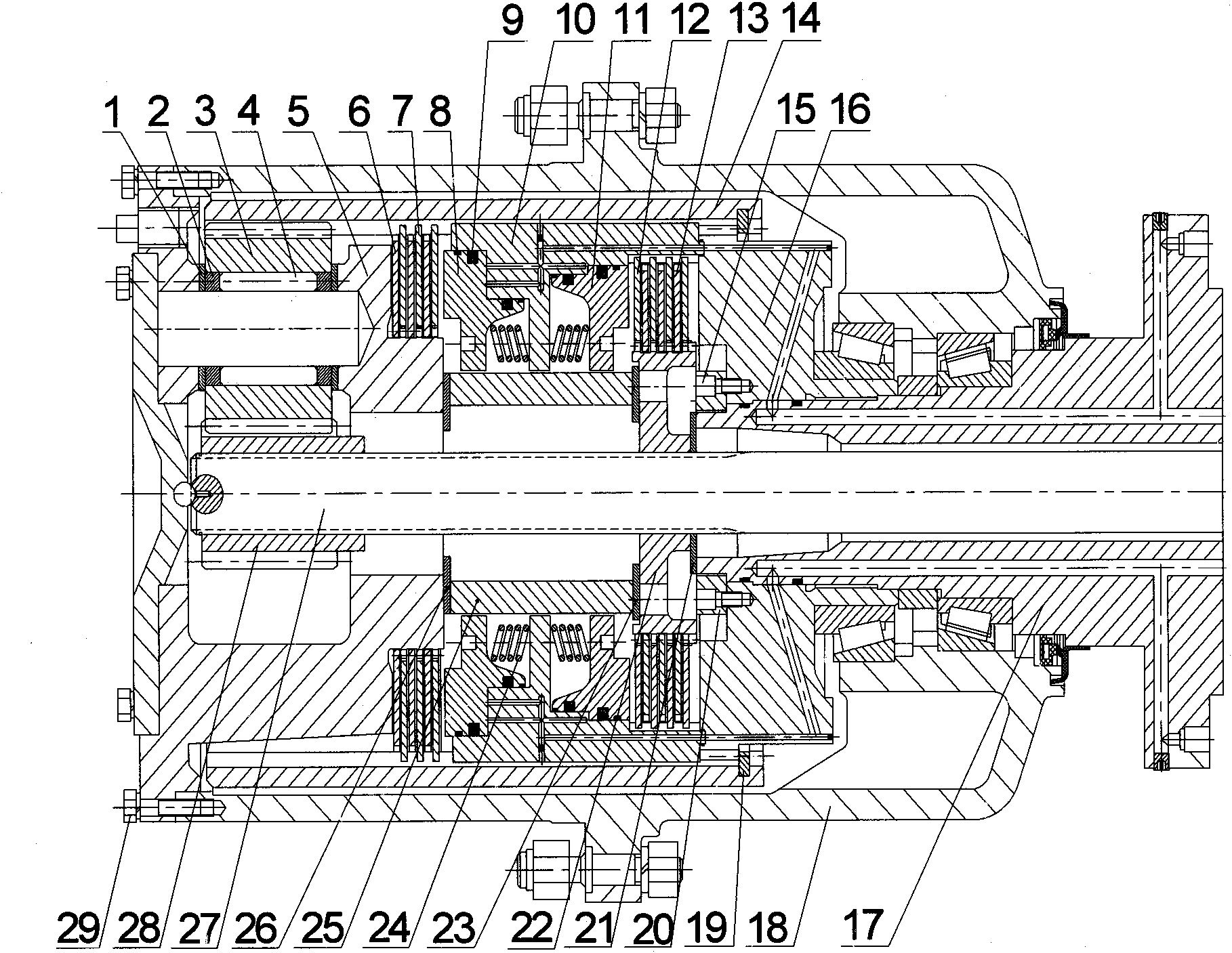

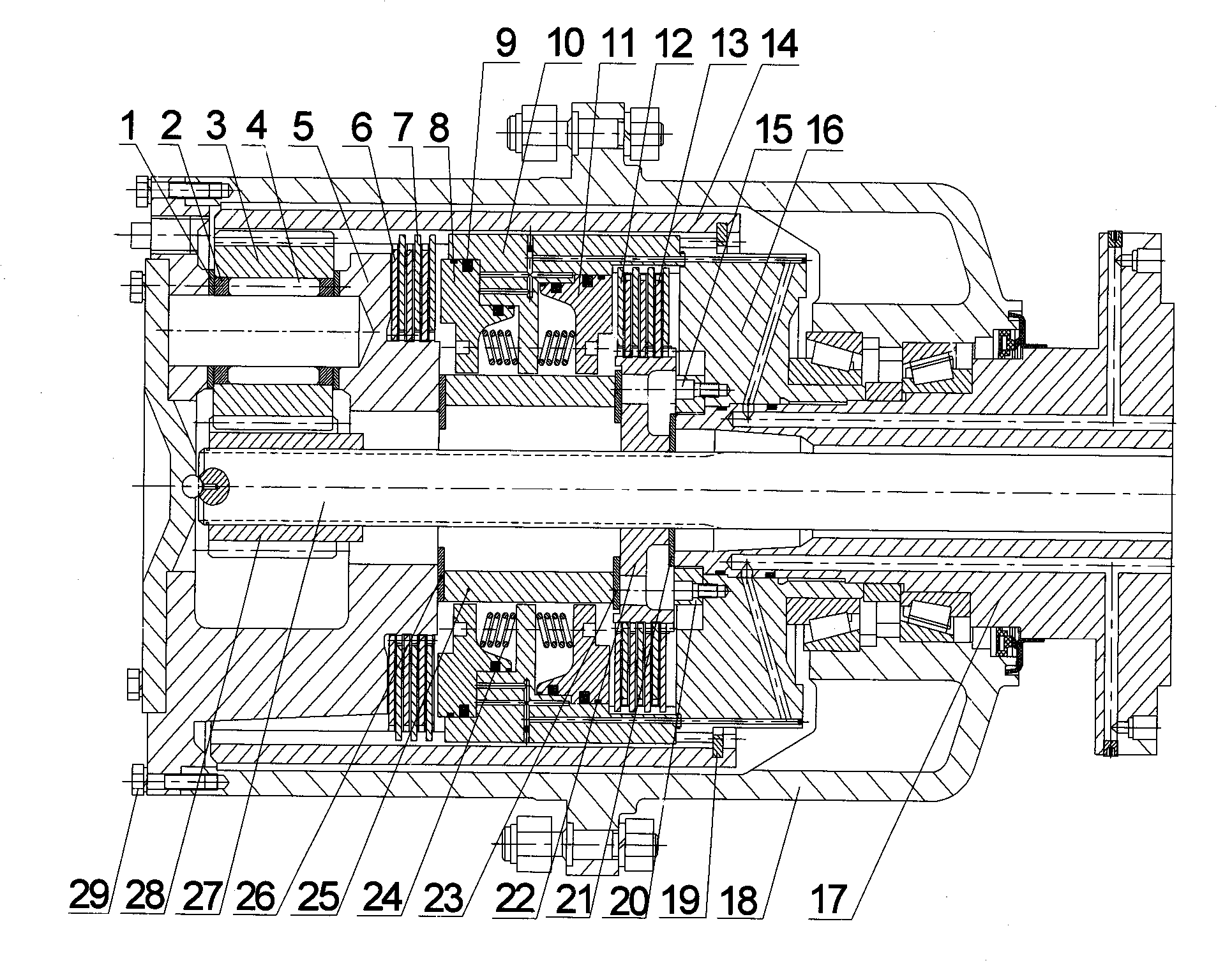

[0013] see figure 1 and 2 , the embodiment of the present invention is provided with left brake, right brake and piston bracket 10;

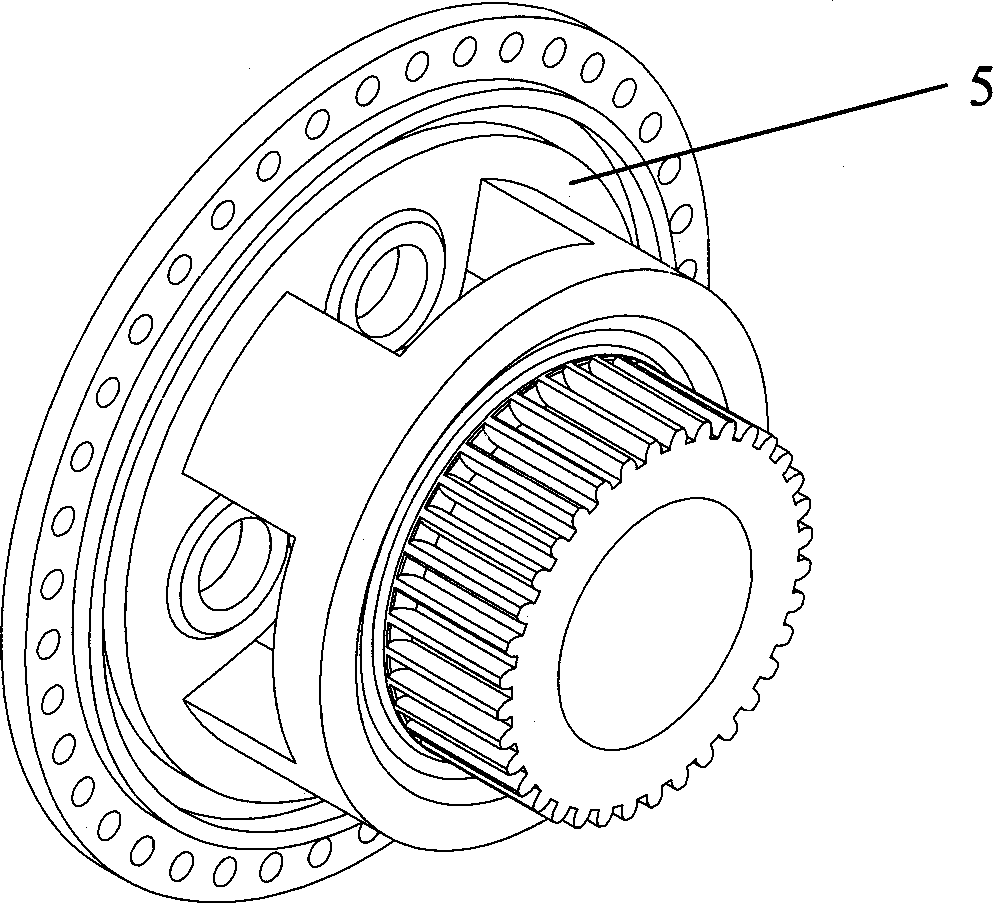

[0014] The left brake is provided with a planetary gear carrier 5, a left dynamic friction plate 6, a left static friction plate 7, a left piston 8, an inner ring gear 14 and a left return spring 241; the outer teeth of the left static friction plate 7 are connected with the inner teeth of the inner ring gear 14 , the inner teeth of the left moving friction plate 6 are connected with the outer teeth of the planetary gear carrier 5, the left moving friction plate 6 and the left static friction plate 7 are spaced apart and equal in number; the outer teeth of the piston bracket 10 are connected with the inner teeth of the ring gear 14, The left piston 8 is installed on the left side of the piston bracket 10, and the left return spring 241 is connected with the piston bracket 10 and the left piston 8 respectively.

[0015] The right brake is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com