Fluid pipeline leakage stopping device and method

A fluid pipeline and pipeline technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of affecting pipeline operations, high cost of plugging, long cycle, etc., and achieve stable and reliable plugging effect. Permanent plugging and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

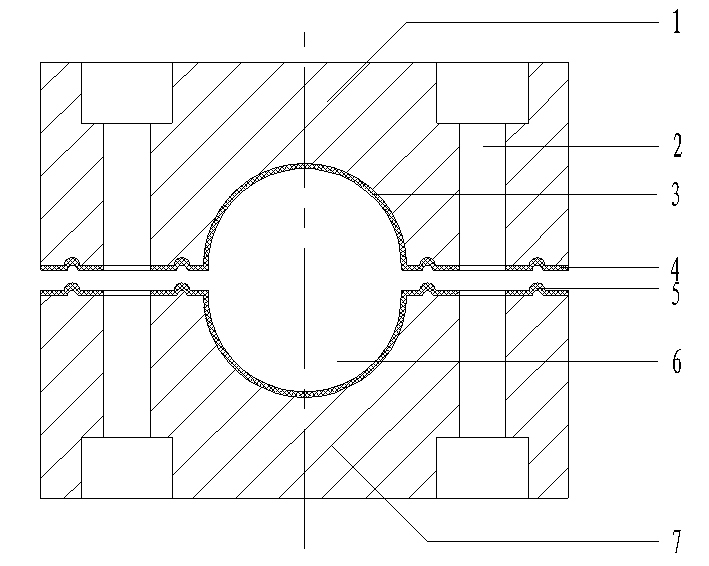

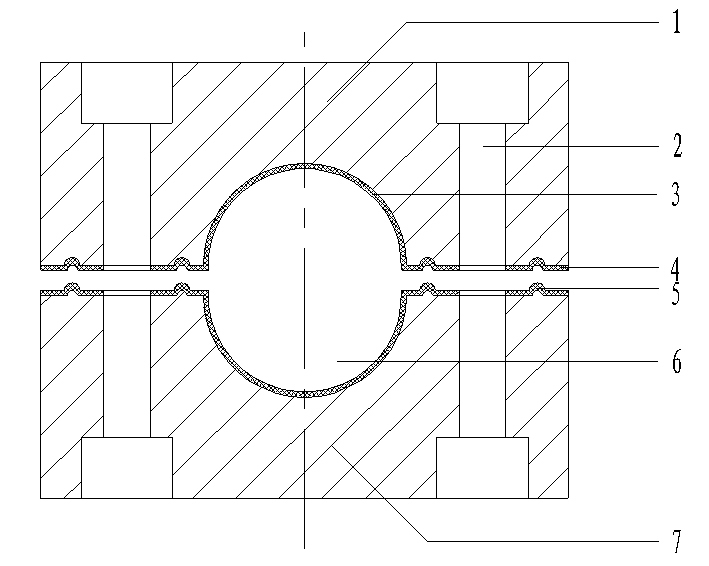

[0018] Such as figure 1 As shown, the plugging device is mainly composed of upper and lower two groove-shaped splints 1, 7 with symmetrical shapes. The groove-shaped splints 1, 7 have a certain width, thickness and length, and the inner side is provided with concave grooves consistent with the curvature of the pipeline. The slot 6 is provided with bolts 2 on both sides, and the inner side of the slot-shaped splint 1, 7 is provided with a soft metal layer 3 made of aluminum casting with a certain thickness, and two pairs of matching semicircular protrusions 5 and grooves are provided on the inner side and outer edge 4.

[0019] The method of the present invention generally includes three steps of casing, positioning, and locking. Specifically, when the method of the present invention is used for plugging, the casing is firstly used, and the position of the casing is selected according to the pressure of the leakage jet. When the pressure is relatively When the pressure is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com