Slag sorting device

A sorting device and sorting chamber technology, which is applied in the field of slag discharge devices of boilers, can solve the problems of no cooling effect, a small adjustable range of fluidization air volume, and a limited adjustment range of the proportion of fine particles returned to meet the requirements of reducing output. , The effect of wide adjustment range and simple structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

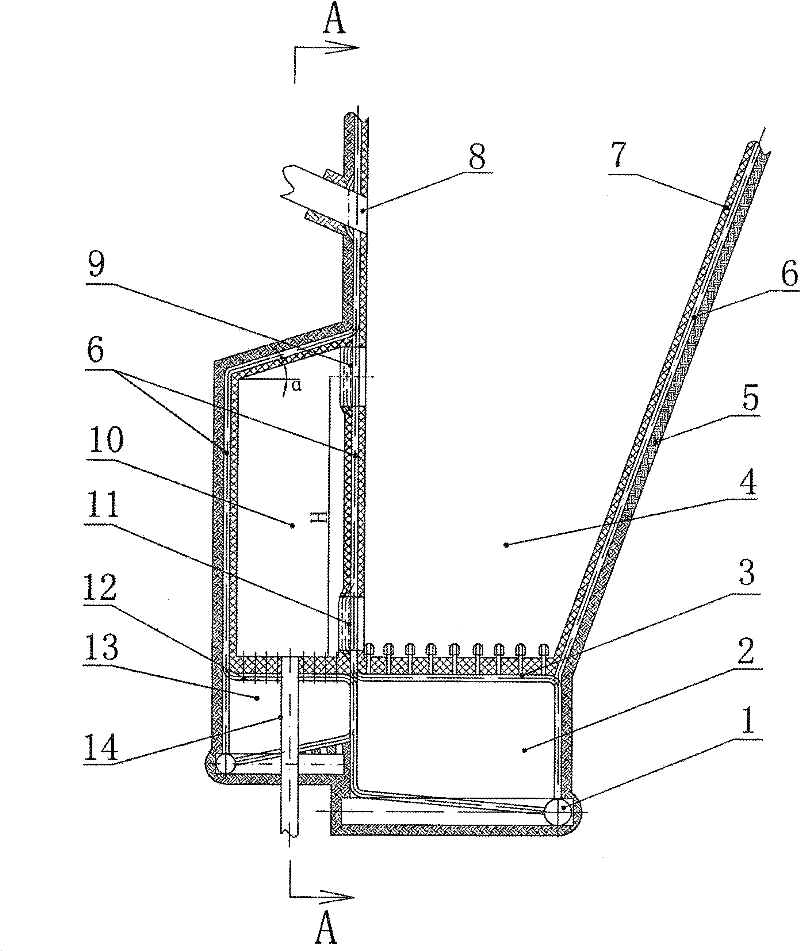

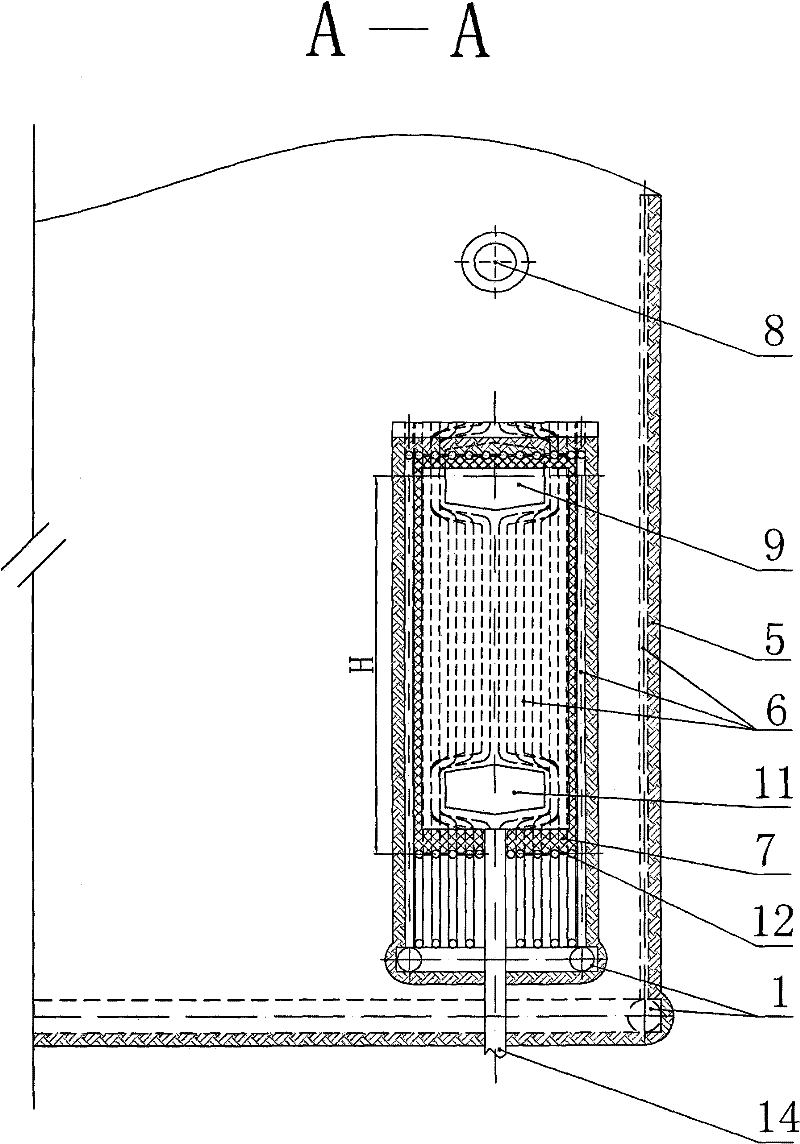

[0024] A kind of slag discharge sorting device of the present embodiment is as figure 1 and figure 2 As shown, it includes a sorting chamber 10, a membrane water wall 6 shared with the furnace 4, a fine ash return port 9, a slag inlet 11, a sorting chamber air distribution plate 12 arranged at the bottom of the The wind plate 12 and the furnace air distribution plate 3 are on the same horizontal plane, and the coarse slag discharge pipe 14 is arranged on the air distribution plate 12 of the sorting room. The surrounding walls and top wall of 10, the air distribution plate 12 of the sorting room and the air chamber of the sorting room are all made of thin-bent membrane water wall 6 of the furnace 4 and welded flat steel; the inclination angle of the top wall of the sorting room 10 is α is 15-25°; there is a slag inlet 11 at the bottom of the membrane water-cooled wall 6 between the sorting chamber 10 and the furnace 4, and a fine ash return port 9 is opened at the joint betwe...

Embodiment 2

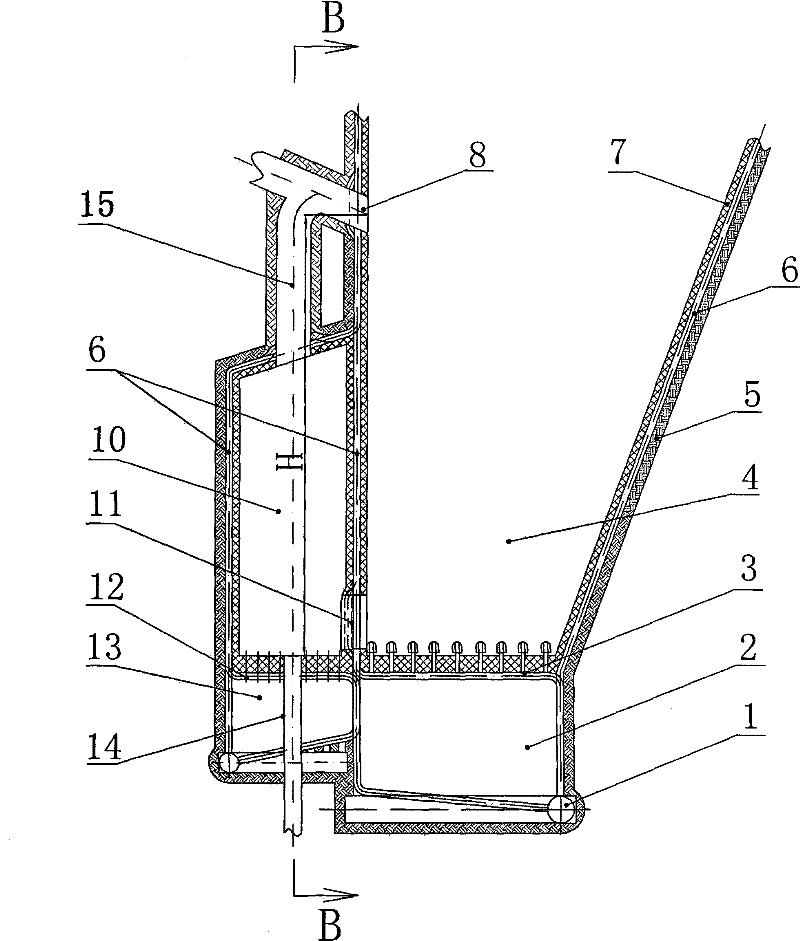

[0026] A kind of slag discharge sorting device of the present embodiment is as image 3 and Figure 4 As shown, the structural difference from Embodiment 1 is: the junction of the top wall surface of the sorting chamber 10 and the furnace 4 is not provided with a fine ash return port 9, and the top center of the sorting chamber 10 is provided with a return exhaust pipe 15. The return material exhaust pipe 15 is connected with the upper secondary tuyere 8 of the furnace 4 . In this embodiment, the upper secondary tuyere 8 of the furnace 4 is used as a channel for fine particles and heat-absorbed fluidized air to return to the furnace 4, which is consistent with the function of the fine ash return port 9 in Example 1. Other structural arrangements are the same as in Embodiment 1.

[0027] According to the furnace size of circulating fluidized bed boilers with different capacities, the vertical distance between the center line of the fine ash return port 9 and the air distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com