Continuous sheet-making machine

A technology of sheet making machine and pole piece, which is applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problems of easily damaged pole pieces, poor product consistency, and low life of knife dies, so as to achieve fast and accurate feeding and high product quality. Stable performance and long mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

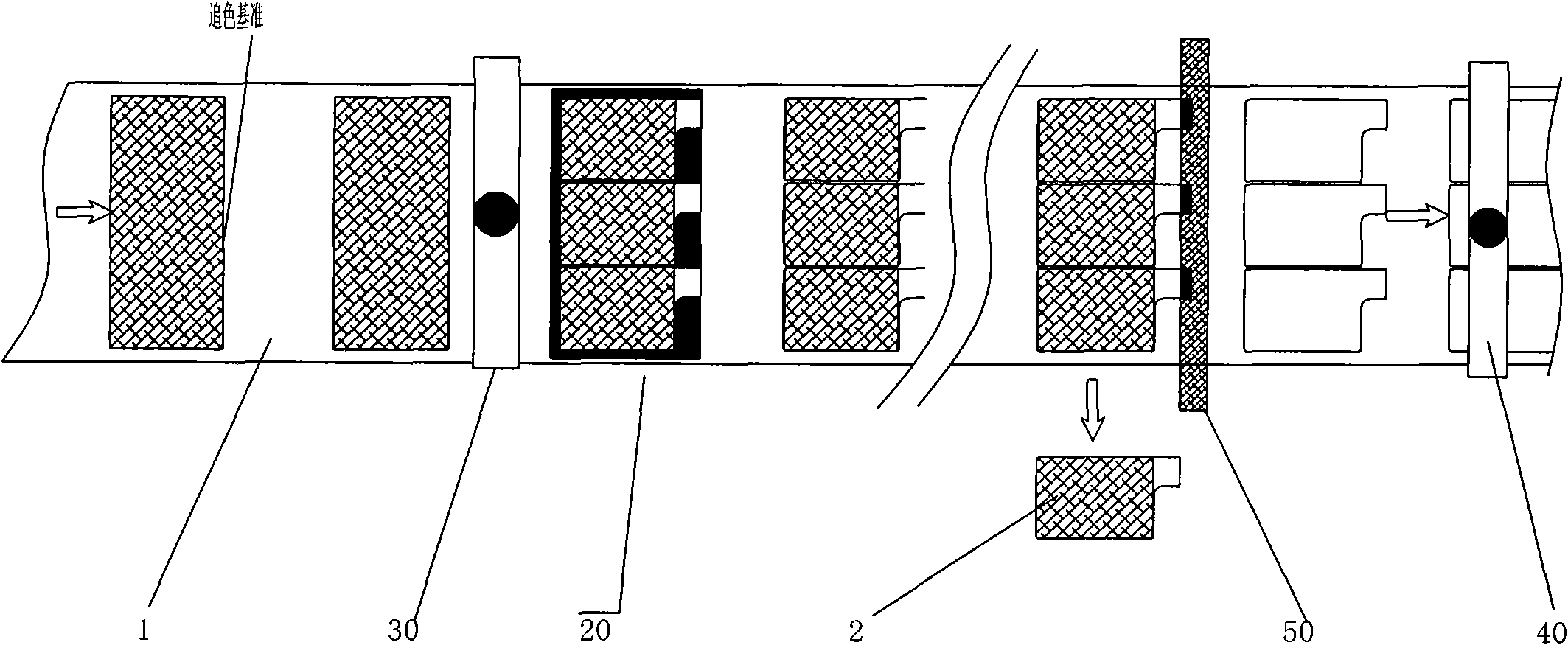

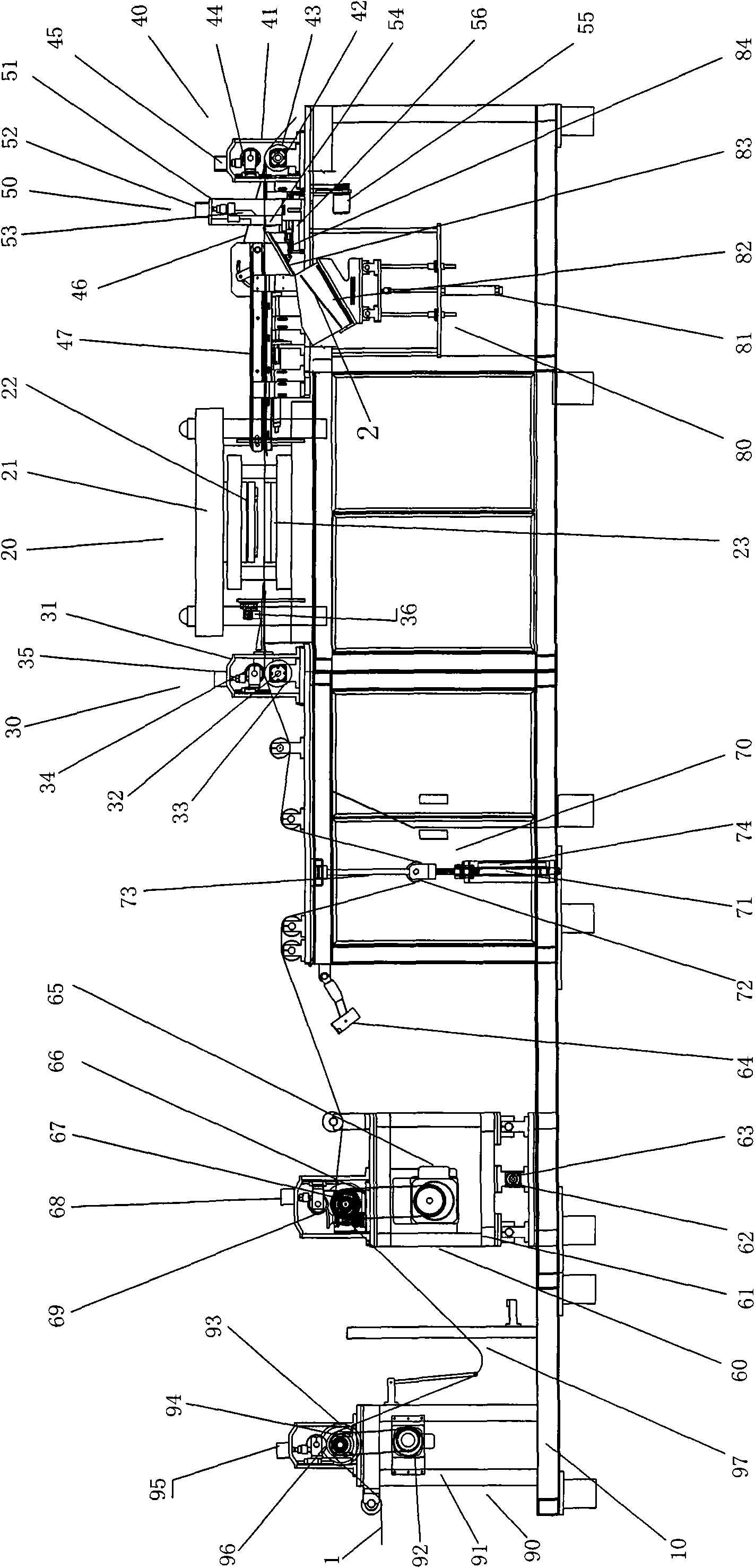

[0051] like figure 1 , 2 , 3, and 4, which disclose the specific structure of the preferred embodiment of the present invention, including a frame 10, a forming mechanism 20, a feeding mechanism 30, a traction mechanism 40, a cutting mechanism 50, an unwinding mechanism 60, a tension Mechanism 70, film receiving mechanism 80, and feeding mechanism 90 configured when the pole piece strip 1 is directly introduced.

[0052] The unwinding mechanism 60 is arranged at the front end of the frame 10, and it includes a base 61, a deviation correction motor 62, a D screw pair 63, a detector 64, a reduction motor 65, a D magnetic coupler 66, a D driving roller 67, a D Cylinder 68, D pressure roller 69, this mechanism can hold the material roll of the pole piece material belt, at this time D cylinder 68, D pressure roller 69 are removed, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com