Swing arm type crane barge for mounting wind power equipment

A wind power equipment and swing arm type technology, which is applied to the field of crane barges for equipment installation in shallow water areas, can solve the problems of easy subsidence of the beach in the intertidal zone, the draft of the crane ship, and the self-heavy weight, etc., and achieves simple structure and wind resistance. Strong, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

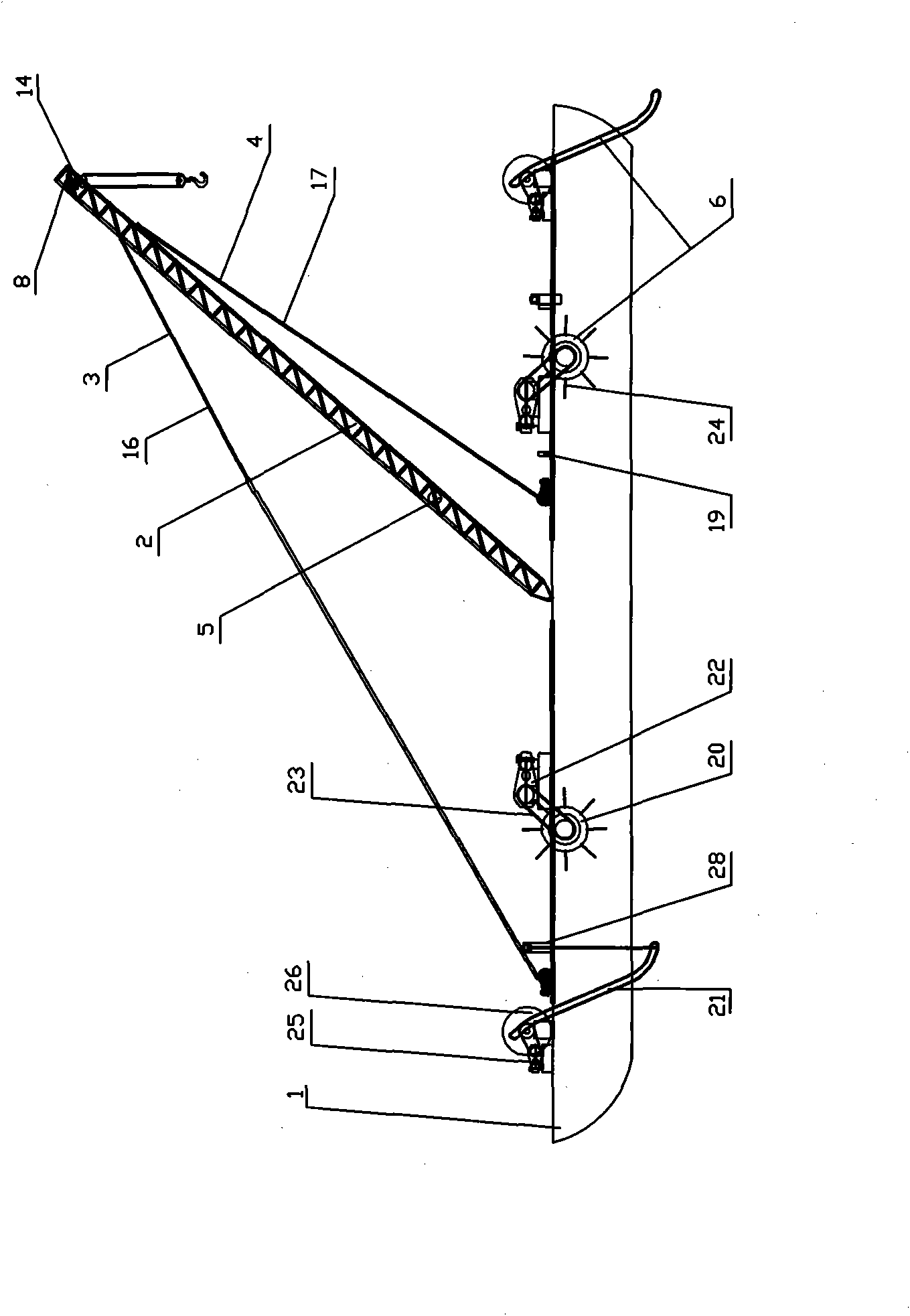

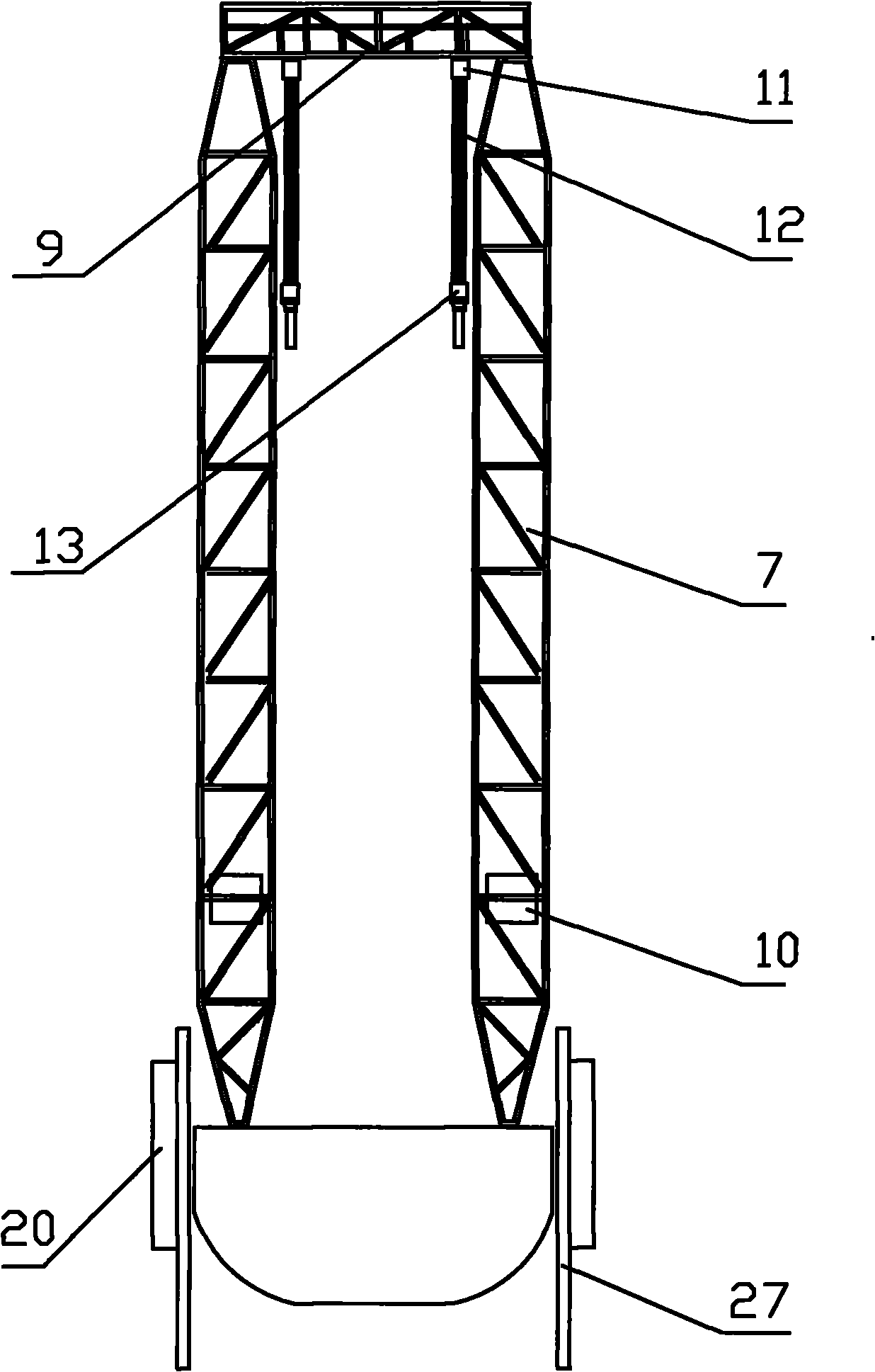

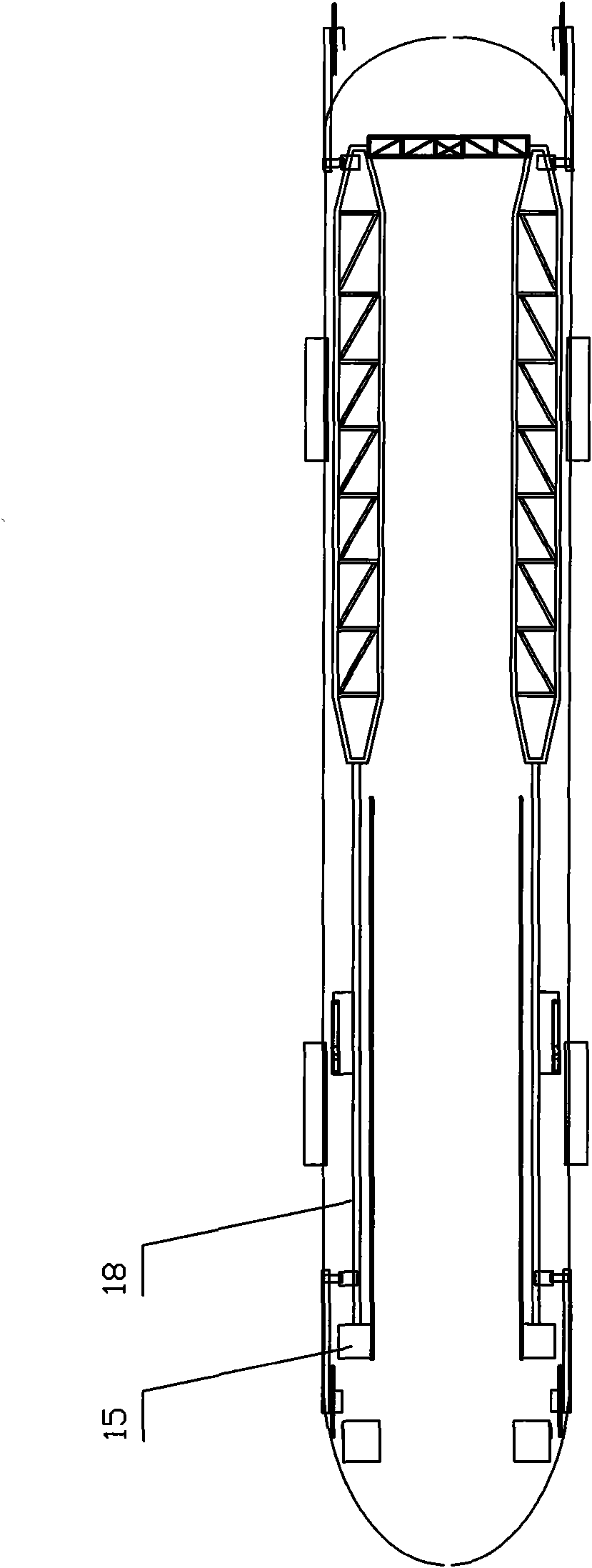

[0020] A swing-type lifting barge for wind power equipment installation, comprising a barge body 1, a gantry arm frame 2, a front luffing mechanism 3, a rear luffing mechanism 4, a lifting mechanism 5, and a barge propulsion device 6, wherein the gantry arm frame 2 is fixed Installed in the middle of the barge body 1, the front luffing system 3 is connected to the upper end of the gantry jib column 7 from the front deck of the barge, and the rear luffing system 4 is connected to the upper end of the gantry jib column 7 from the barge rear deck, and the front and rear luffing mechanisms cooperate with each other , drive the gantry arm frame 2 and the hoisting mechanism 5 mounted on it to swing to realize the object moving forward and backward; two sets of hoisting mechanisms 5 are installed on the gantry arm frame 2, wherein the wire rope 12 on the hoist 10 bypasses the fixed pulley block 11 to drive The hook pulley block 13 moves vertically to lift objects, and barge propulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com