Portal crane current collector

A technology of gantry cranes and collectors, which is applied in the direction of load hanging components, transportation and packaging, etc., and can solve problems such as the small expansion and contraction range of collectors, which cannot effectively alleviate the wear of carbon brushes, the high frequency of collector damage, and short-circuit faults in lines. Achieve the effect of increasing the telescopic range, prolonging the service life, and avoiding short-circuit faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

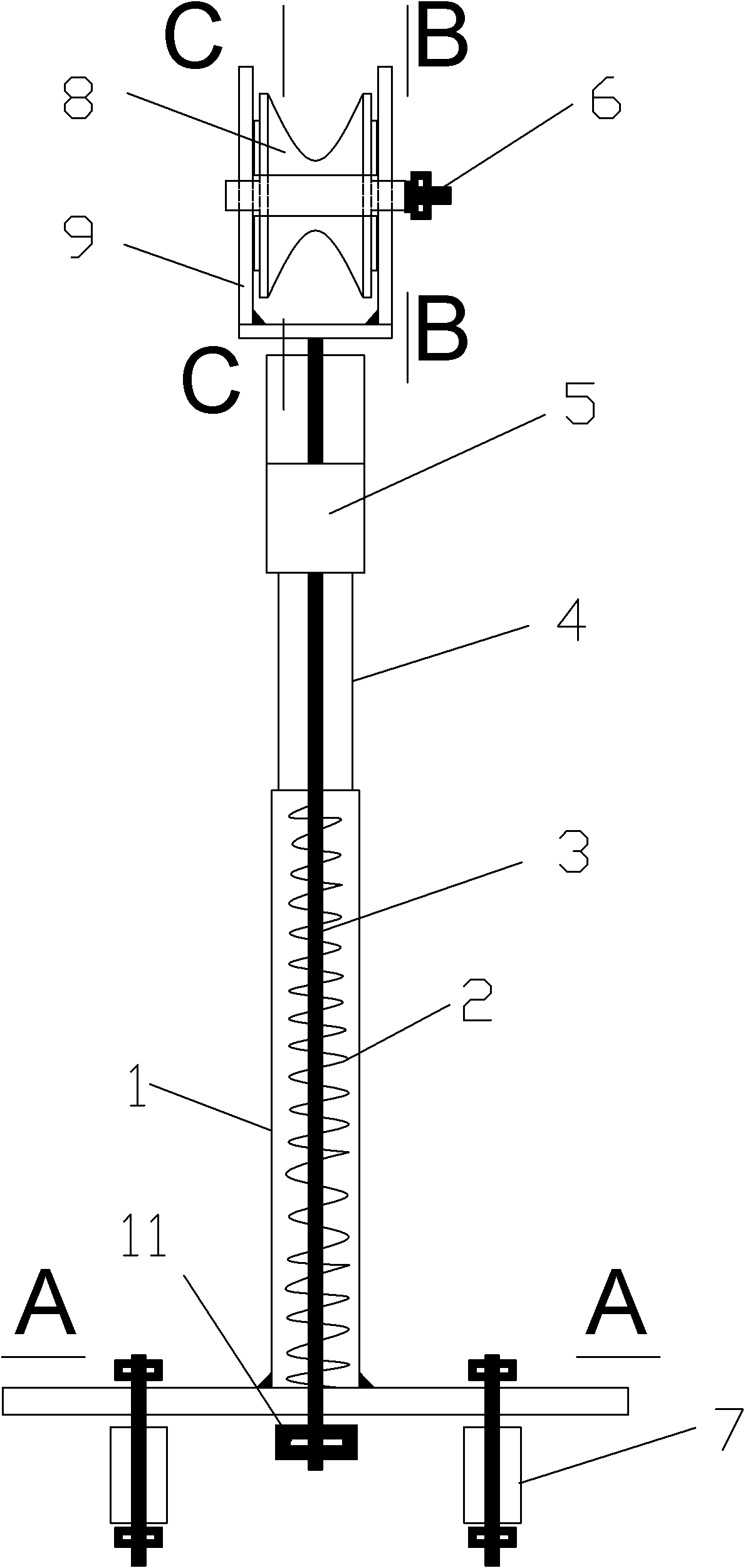

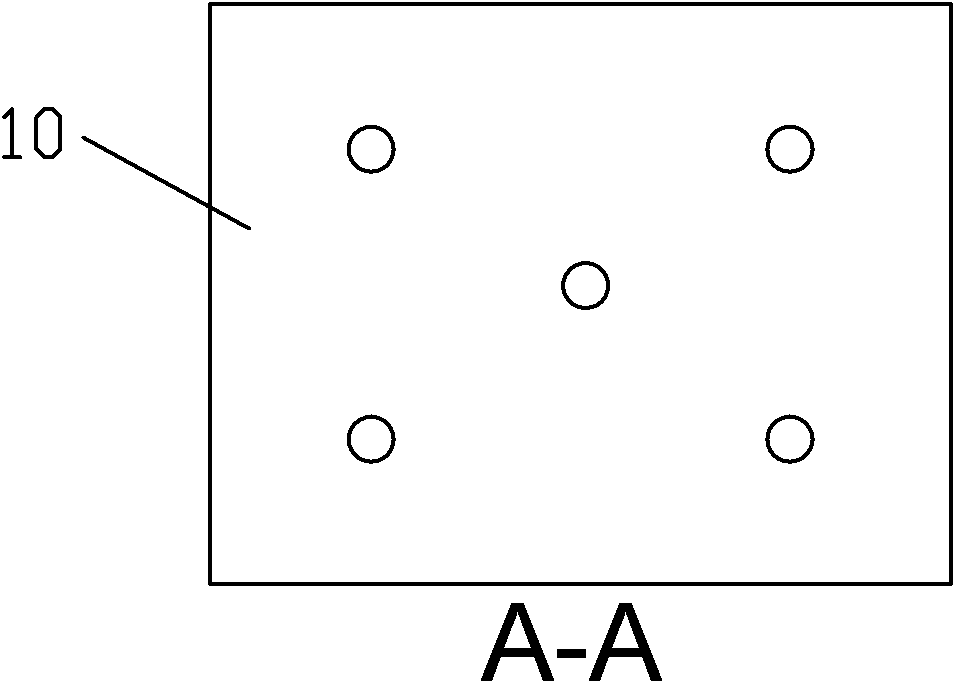

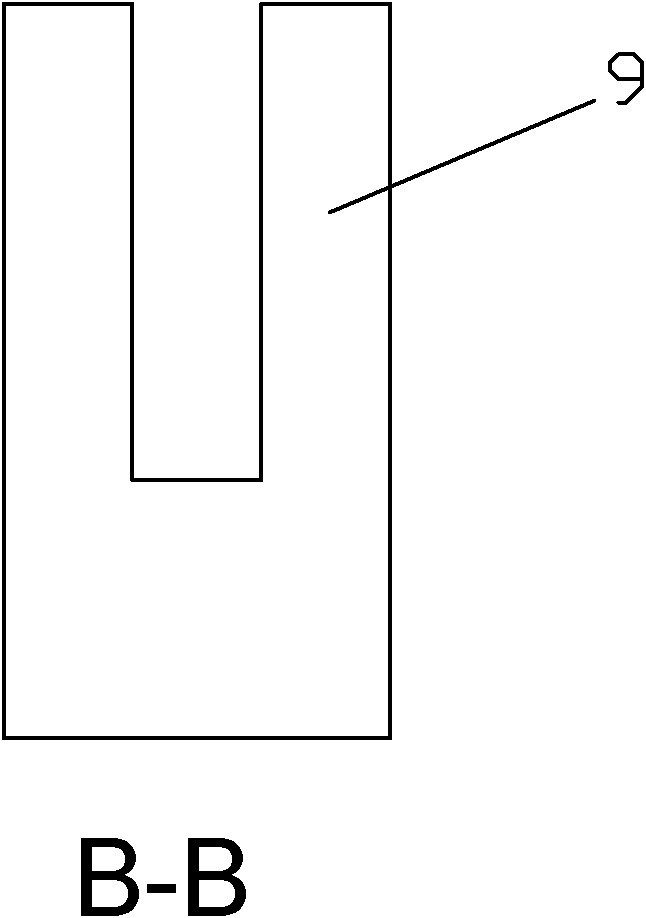

[0014] figure 1 It is a structural schematic diagram of an embodiment of the present invention, figure 2 for figure 1 A-A sectional view of, image 3 for figure 1 The B-B sectional view, Figure 4 for figure 1 C-C sectional view of C-C, including insulating base, telescopic rod, nylon insulating rod, walking pulley 8 and pulley base 9.

[0015] The insulating base consists of a 2mm thick steel plate 10 and an insulating porcelain vase 7 connected on the steel plate 10, and the insulating porcelain vase 7 is connected with the steel plate 10 by bolts to play an insulating role.

[0016] The pulley base 9 is U-shaped, and the walking pulley 8 is connected in the pulley base 9 through a bearing, and the sliding wire is wound on the walking pulley 8; the bearing end has a 25mm thread, and is connected with the cable through the copper nose 6. The walking pulley is a copper wheel, which has a 2mm cap on the surface after lathe machining to reduce the frictional resistance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com