Busing type electronic thermostat

A thermostat and bushing type technology, applied in the direction of machine/engine, coolant flow control, engine components, etc., can solve the problems of inaccurate control, insufficient response of thermostat temperature, low sensitivity, etc., to reduce Effects of pollution, wear reduction, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

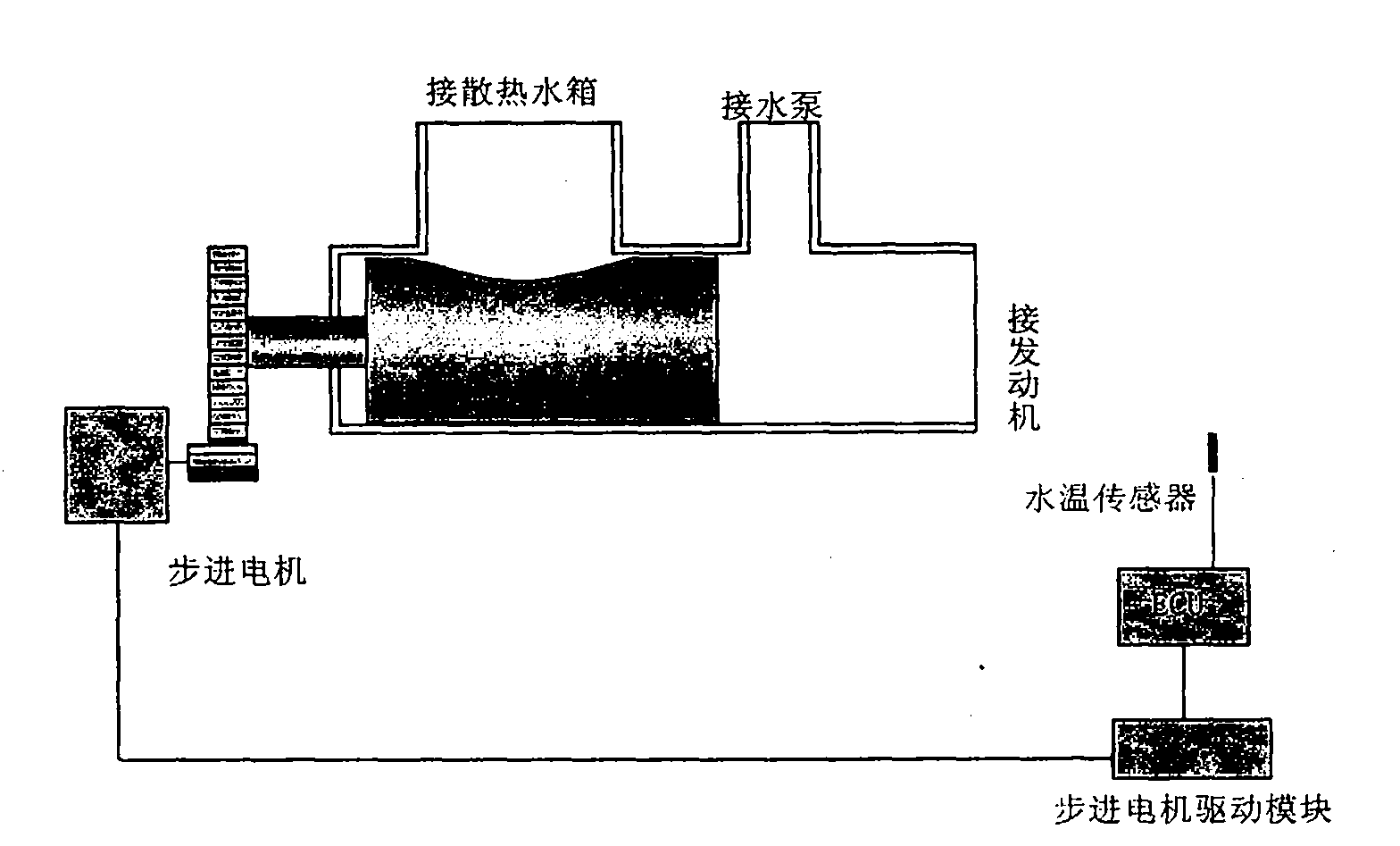

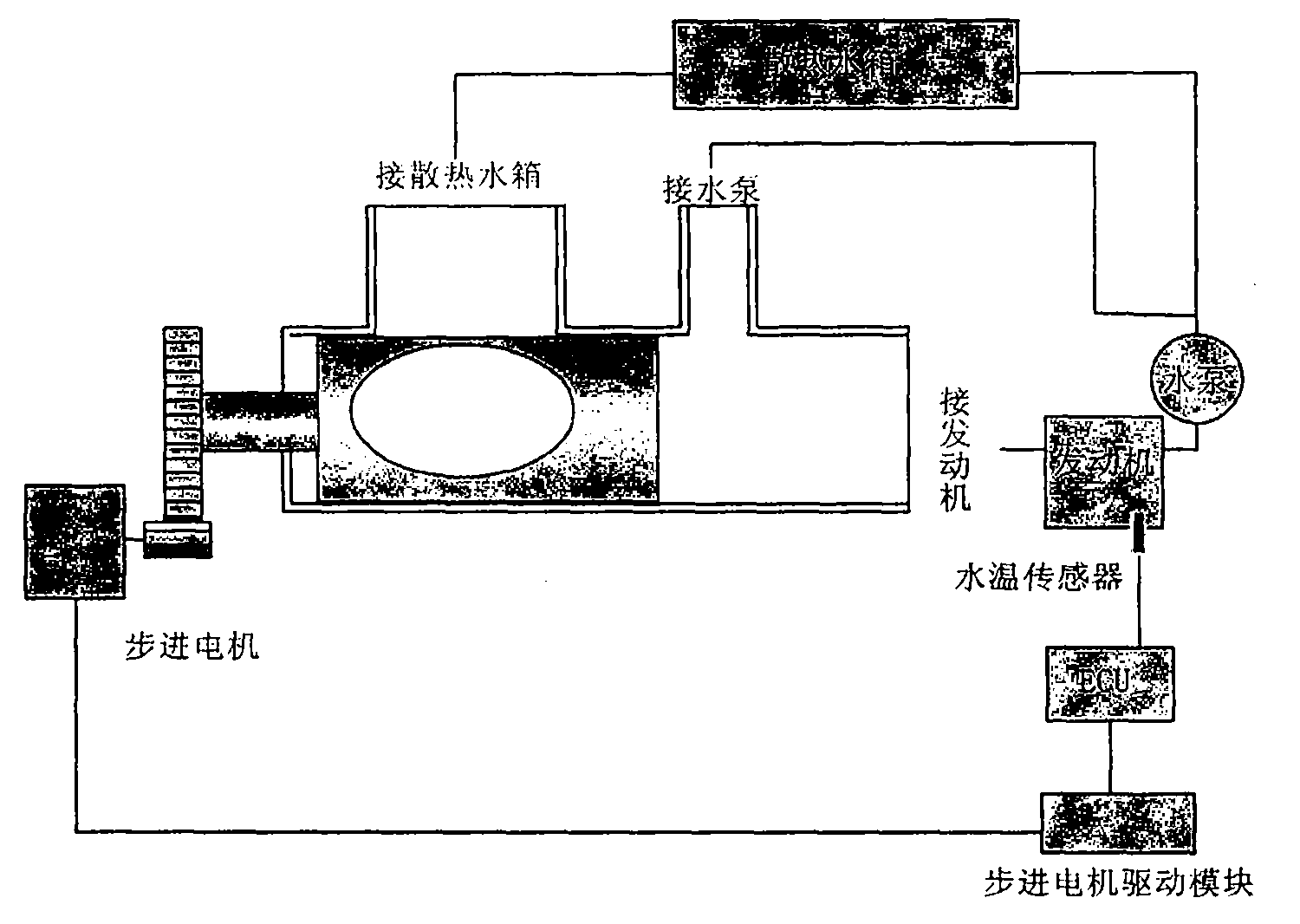

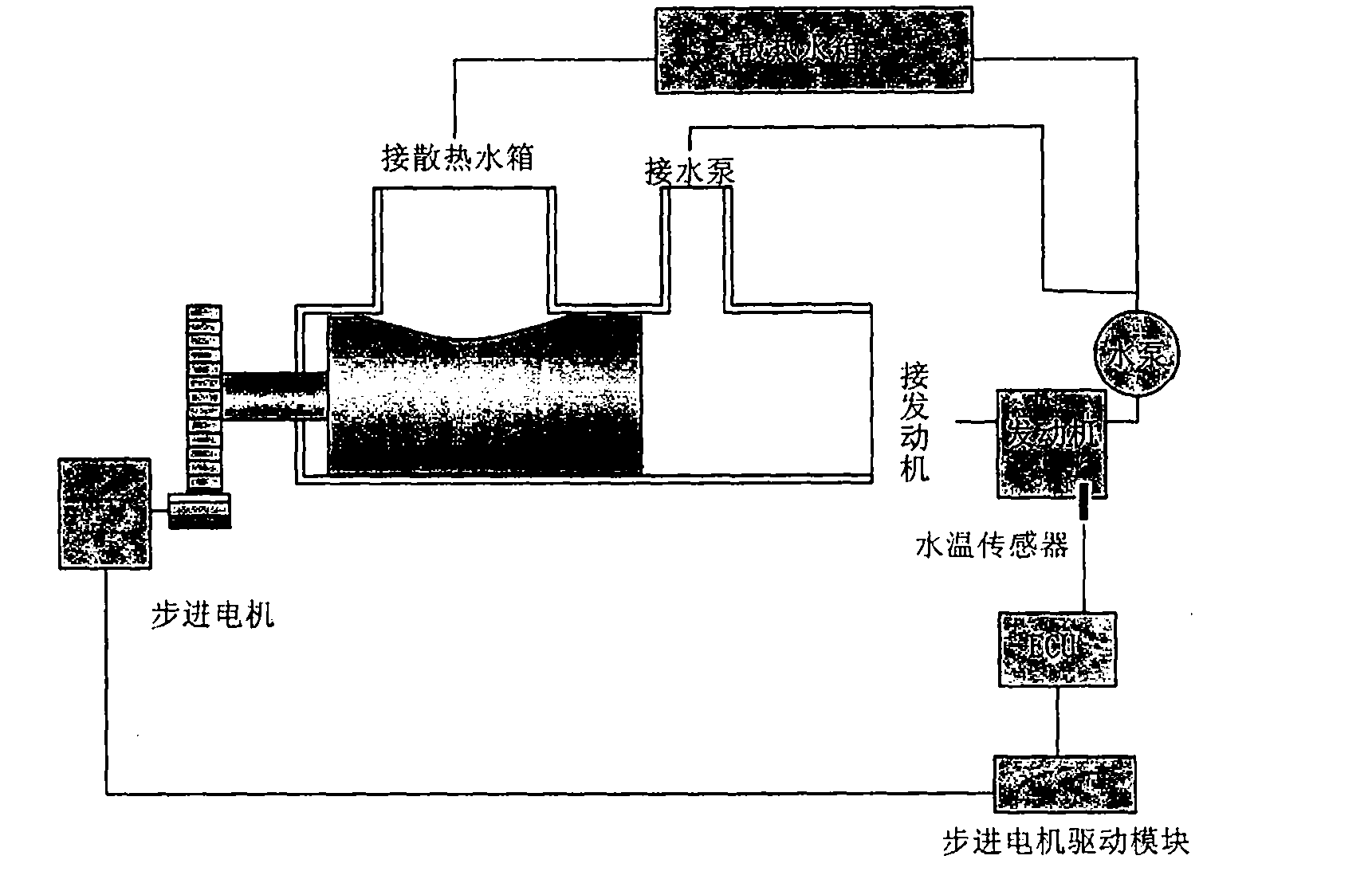

[0016] After the engine is started, it is in a cold running state. At this time, the coolant is in a small cycle, and the coolant should be prevented from circulating through the radiator (large cycle). The inner pipe of the thermostat is in the initial state, and the coolant flows from the engine water jacket through the thermostat small circulation interface to the circulation pump for small circulation (see figure 2 ). After the engine runs for a period of time, when the coolant in the water jacket reaches a certain temperature (this temperature can be set according to the specific engine), the ECU sends a signal to the drive module, and the drive module controls the stepper motor to rotate through an angle to drive the inner tube to rotate At one angle, the large hole on the inner tube is aligned with the large circulation interface on the shell, so that the coolant flows from the engine water jacket through the thermostat large circulation interface to the radiating water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com