Ultrathin LED backlight module

A backlight module, ultra-thin technology, applied in the field of ultra-thin LED backlight modules, can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

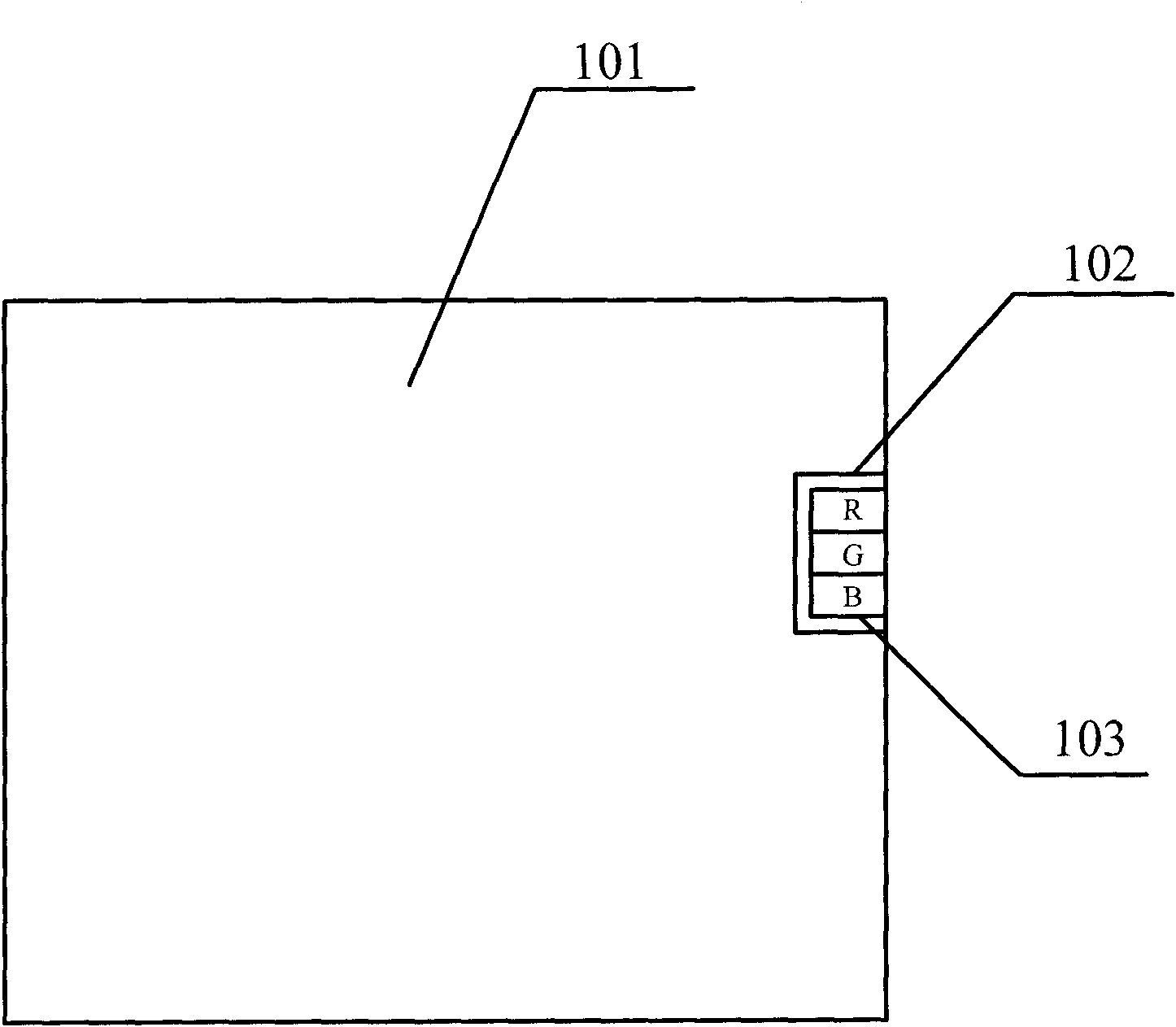

[0024] like figure 1 As shown, this embodiment provides an ultra-thin LED backlight module, wherein the ultra-thin backlight module includes several LEDs 103 and one or more light guide plates, such as one light guide plate 101 .

[0025] Each LED 103 includes one or more red LED thin film chips R, one or more green LED thin film chips G and one or more blue LED thin film chips B, for example, including one red LED thin film chip R, one green LED thin film chip G and a blue LED film chip B, or include a red LED film chip R, two green LED film chips G and a blue LED film chip B.

[0026] Moreover, the LED thin film chips in each LED 103 are connected side by side to form a polygon. For example, the LED thin film chips are connected side by side in a straight line to form a rectangle, or connected side by side to form a triangle, or a circle, etc.; The thickness of one LED thin film chip can be the same or different, and the shapes and sizes of LED thin film chips of different ...

Embodiment 2

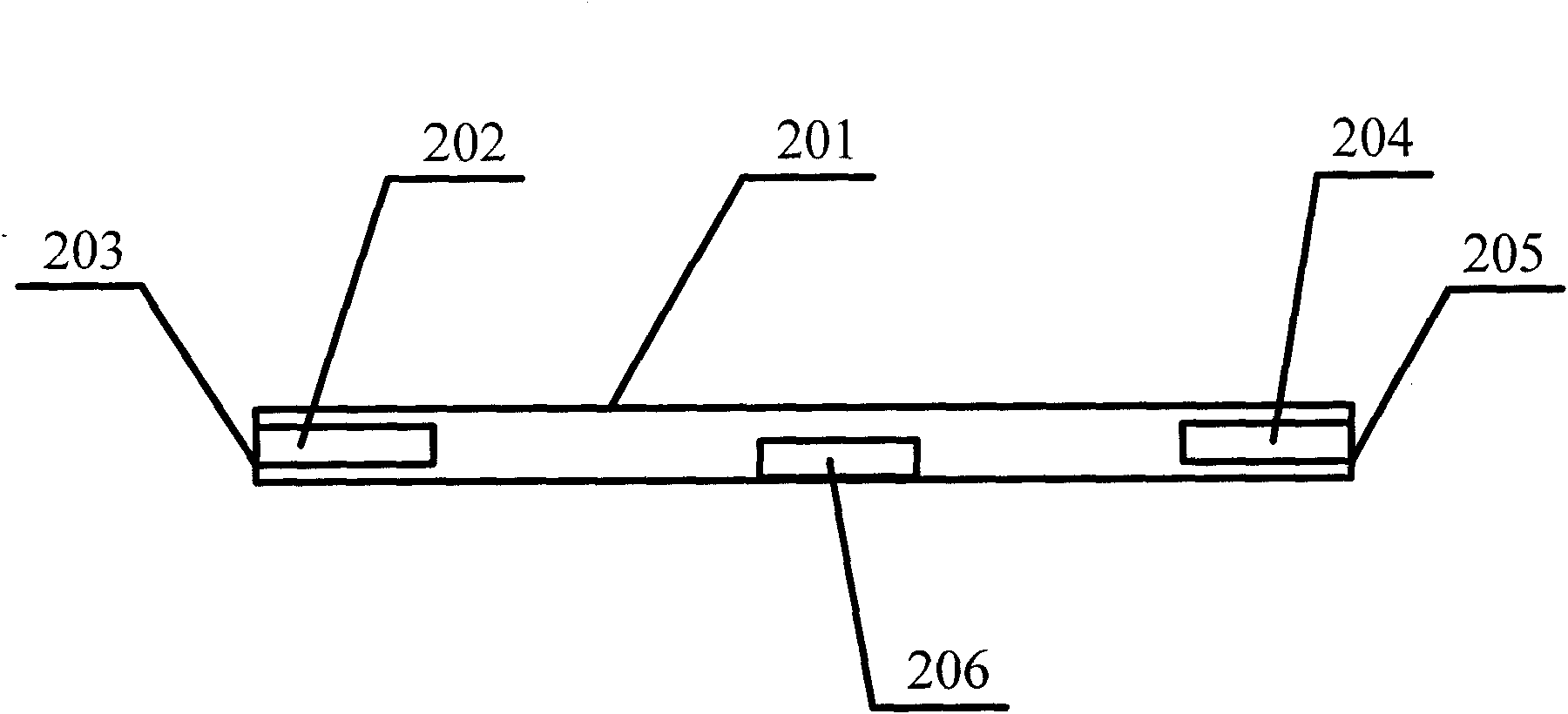

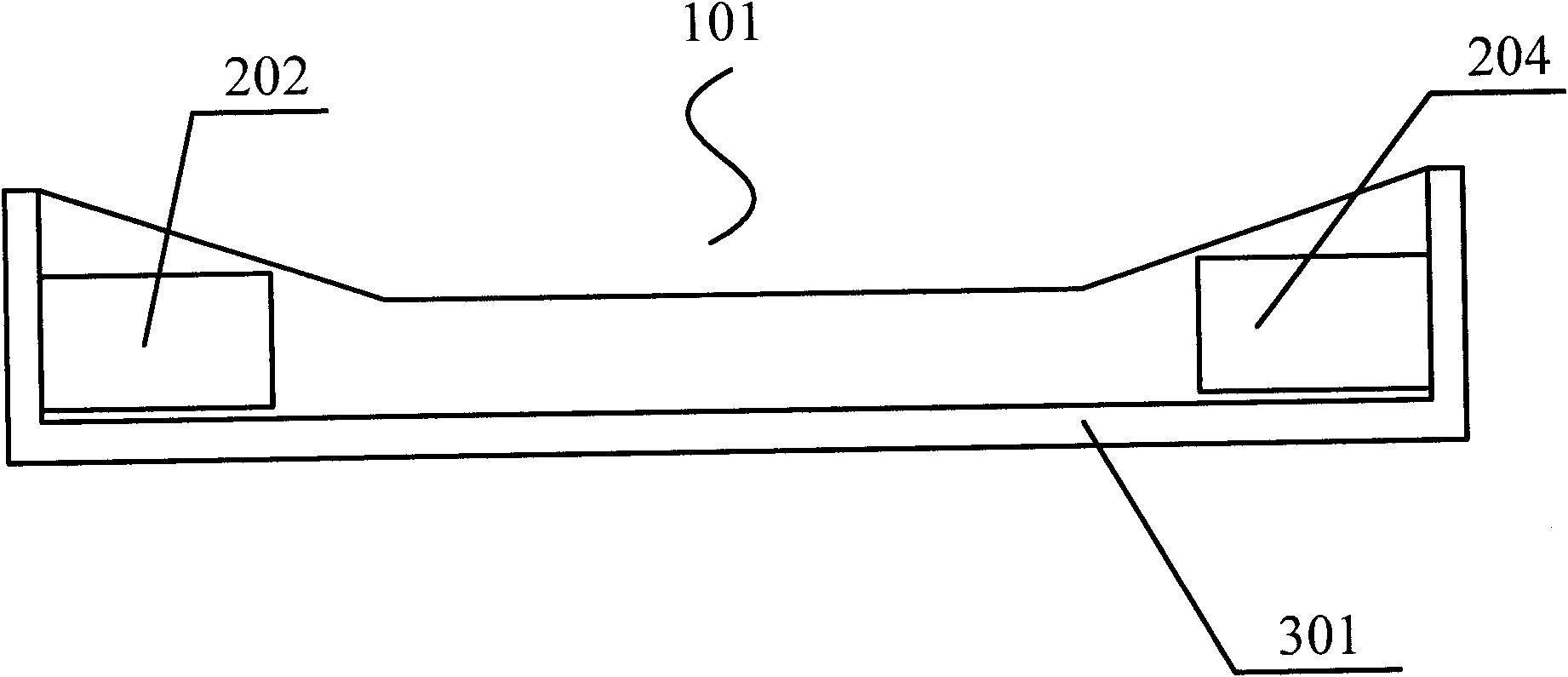

[0031] like figure 2 As shown, on the basis of the above examples, in the ultra-thin LED backlight module provided by this embodiment, LEDs are embedded in two or more sides of the light guide plate, for example, on the light guide plate LED202 is set on the side 203 of the light guide plate, LED202 is embedded in the light guide plate, LED204 is set on the side 205 of the light guide plate, LED204 is also embedded in the light guide plate, and the side 203 and side 205 are The opposite sides of the light guide plate, in this way, can make the distribution of the LEDs more uniform, and the light guide uniformity is good. For example, when the light guide plate is quadrilateral, rectangular, square or parallelogram, the LEDs are respectively located on two non-adjacent sides.

[0032] Moreover, when each LED is embedded in the light guide plate, it is parallel to the light guide surface 201 of the light guide plate, that is, the thickness direction of each LED is consistent w...

Embodiment 3

[0035] On the basis of the above examples, in the ultra-thin LED backlight module provided by this embodiment, the thickness of each LED film chip is set to 0.1mm-0.5mm, and preferably 0.3mm-0.4mm, ensuring that the LED The thickness of the thin-film chip is set to be the smallest, the luminous brightness per unit area is the strongest, and the number of P-N junctions set in each LED thin-film chip is the most reasonable. For example, the thicknesses of the LED thin film chips are respectively or both set to 0.1mm, 0.12mm, 0.15mm, 0.21mm, 0.24mm, 0.25mm, 0.36mm, 0.38mm, 0.385mm, 0.396mm, 0.399mm, 0.41mm, 0.5mm wait. For different light guide plates, the thickness of the LED film chip is set according to different product requirements.

[0036]Moreover, the ratio of the thickness of the LED to the thickness of the light guide plate is 0.8:1-1:1, because when the thickness of the light guide plate is greater than or equal to the thickness of the LED, the utilization rate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com